Portable automatic following wire pay-off spool

A self-following, portable technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., it can solve the problems of time-consuming and labor-intensive wire resistance, inconvenient transportation and storage in changing places, and scattered problems, so as to reduce labor Strength, save manpower, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

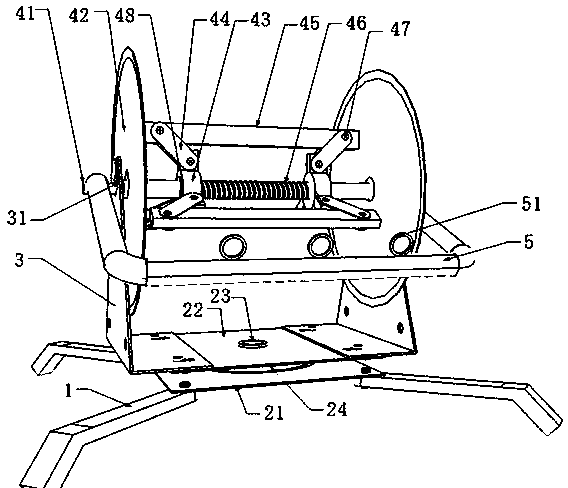

[0030] The following are specific examples to further describe the technical solution, but the present invention is not limited to these examples.

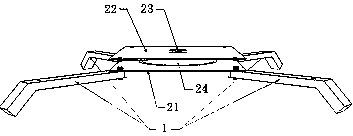

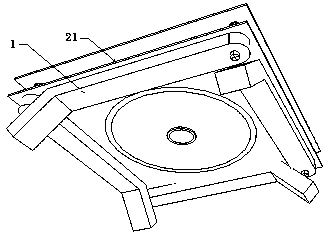

[0031] When using, first open the four supporting claws 1 ( figure 2 ), which will place the entire device firmly.

[0032] Hold the handle 5 to remove the self-adaptive spool assembly 4 from the bracket 3 along the quick loading and unloading opening 31 .

[0033] Take off the baffle plate 42 on any side; place the side of the baffle plate removed vertically on the bottom surface or other planes. Compress the three support rods 45 toward the axis 41 with both hands; then hold the support rods tightly with one hand to restrain their expansion, (the strength does not need to be very large) put the wires on the three support rods with the other hand, let go The support rods 45 are released so that the support rods 45 are braced outwardly, tightly against the inner diameter of the bundle of wires. Subsequent wire placement does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com