System and method for safety monitoring control of crane brake

A technology of safety monitoring and brakes, which is applied in the direction of brake types, safety devices, mechanical equipment, etc., can solve problems such as heavy lifting devices, loss of braking torque, and limited strokes, so as to ensure safe use, reduce maintenance and manufacturing costs, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

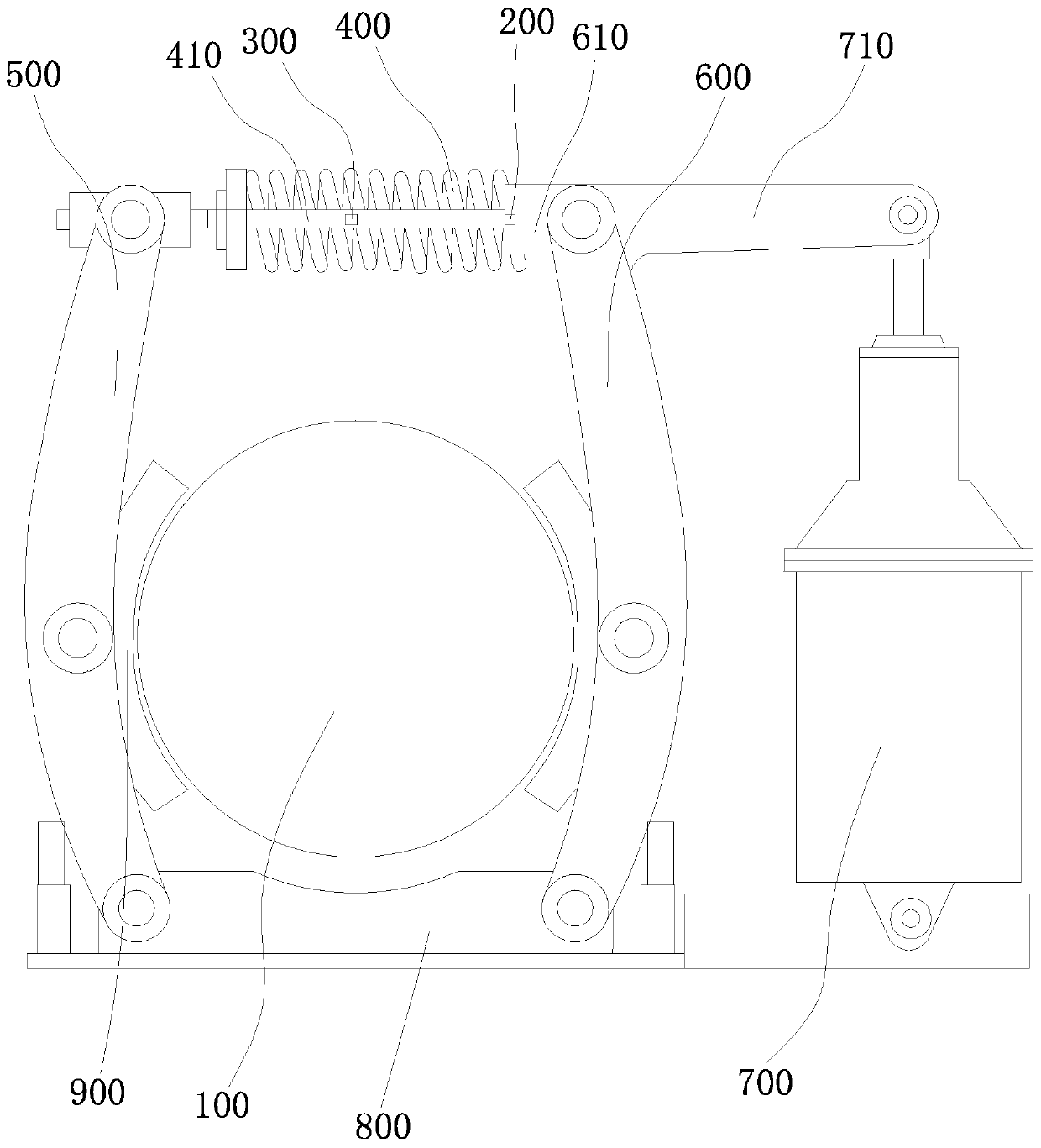

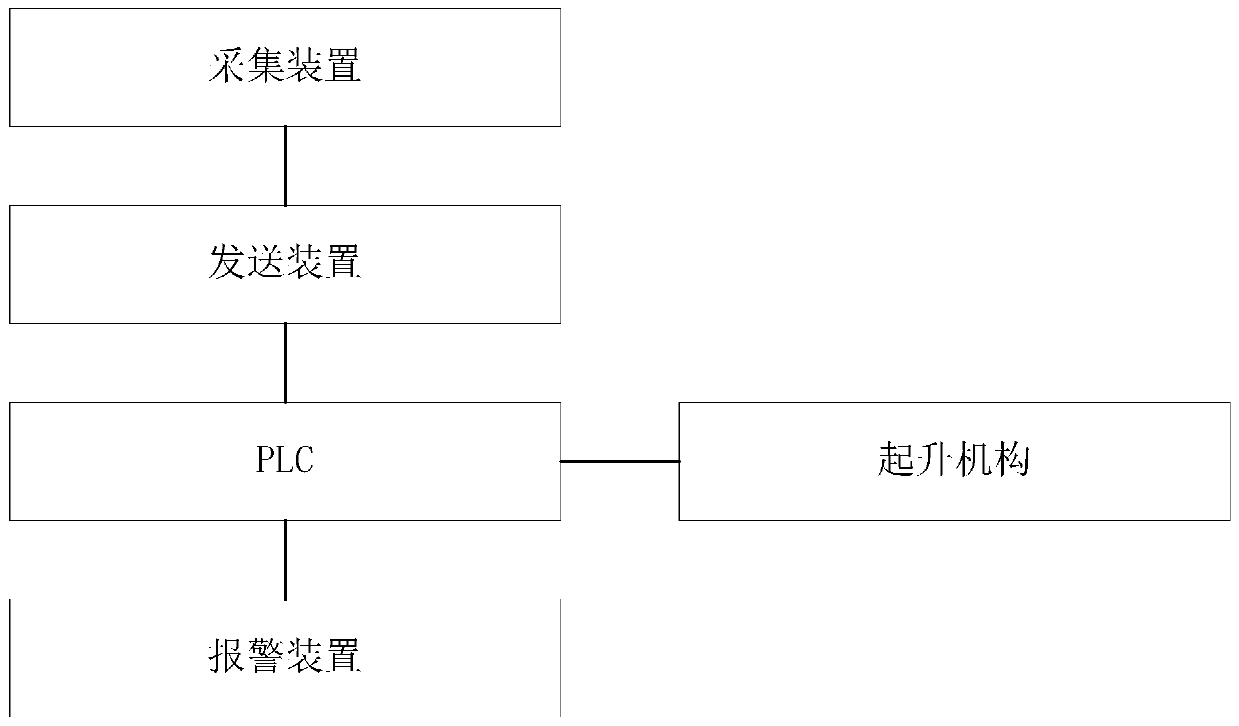

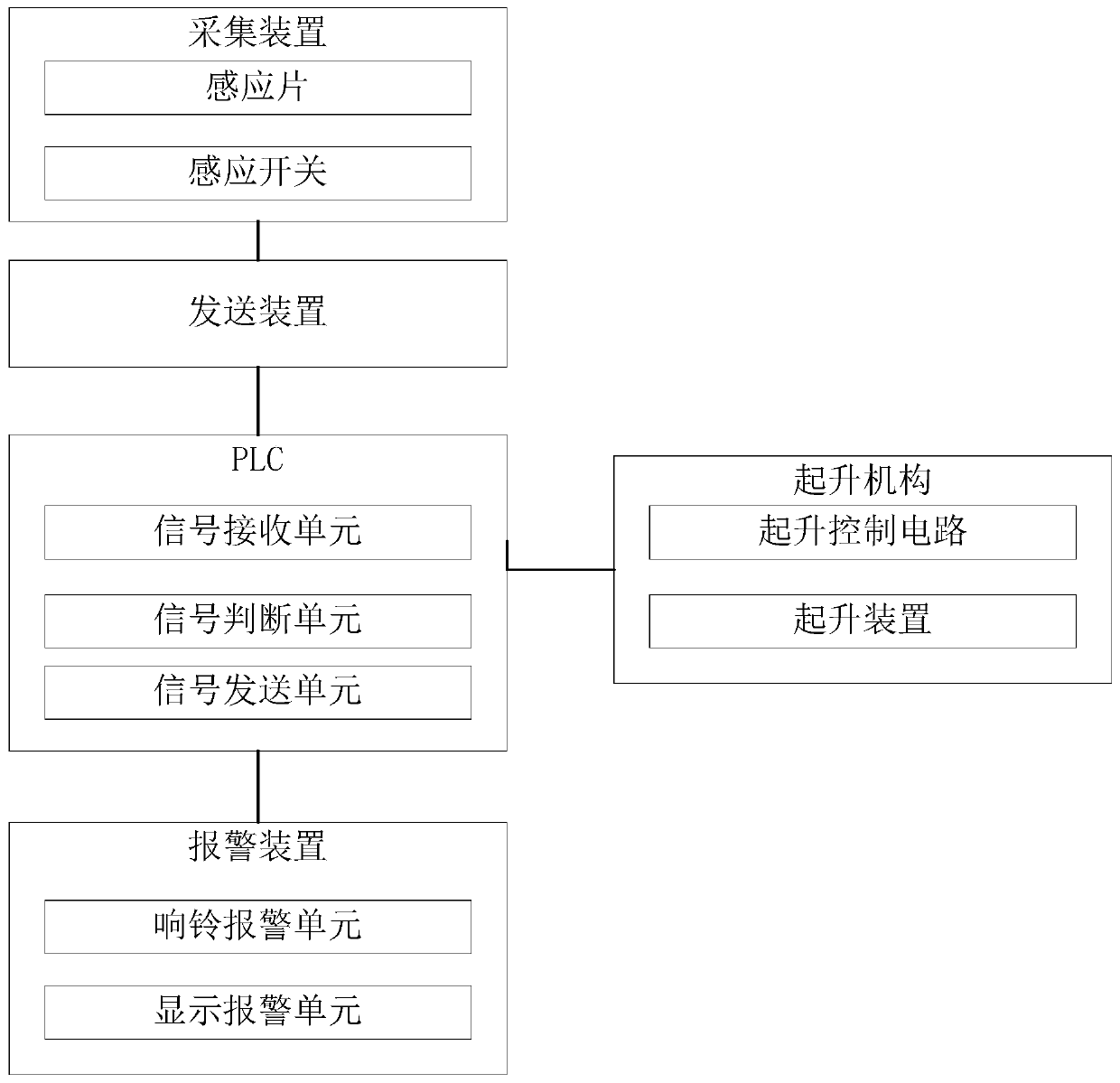

[0057] This embodiment provides a system for safety monitoring and control of crane brakes, which is used to solve the problem of potential safety hazards when multiple sets of brakes need to be installed to solve the brake torque loss, such as Figure 1 to Figure 3 As shown, the system includes:

[0058] A system for crane brake safety monitoring and control, comprising: a collection device, a sending device, a PLC, a lifting mechanism, and an alarm device;

[0059] The collection device is used to collect the compression amount of the brake spring when the brake is released;

[0060] The sending device is used to send the collected compression amount of the brake spring to the PLC when the brake is released;

[0061] PLC, used to control the stop of the lifting mechanism when the elongation of the brake spring is equal to the sum of the limit compensation stroke and the lifting height of the push rod when the brake is applied, and send a preset alarm signal to the alarm dev...

Embodiment 2

[0087] This embodiment provides a method for crane brake safety monitoring and control, such as figure 1 , Figure 4 as well as Figure 5 As shown, the method includes the steps of:

[0088] A method for crane brake safety monitoring and control, comprising the steps of:

[0089] S1: collect the compression amount of the brake spring when the brake is released;

[0090] S2: Send the collected compression amount of the brake spring to the PLC when the brake is released;

[0091] S3: Judging by PLC whether the compression of the brake spring is equal to the sum of the limit compensation stroke and the lifting height of the push rod when the brake is released;

[0092] S4: If the compression amount of the brake spring is equal to the sum of the limit compensation stroke and the lifting height of the push rod when the brake is released, control the lifting mechanism to stop lifting, and send a preset alarm signal to the alarm device;

[0093] Further, step S1 includes:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com