Novel artificial fur weaving machine

A technology of artificial fur and knitting machines, which is applied in knitting, textiles and papermaking, etc. It can solve problems such as ghosting and uneven fiber distribution, and achieve the effects of reducing labor intensity, uniform fiber distribution, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be further described based on preferred embodiments with reference to the accompanying drawings.

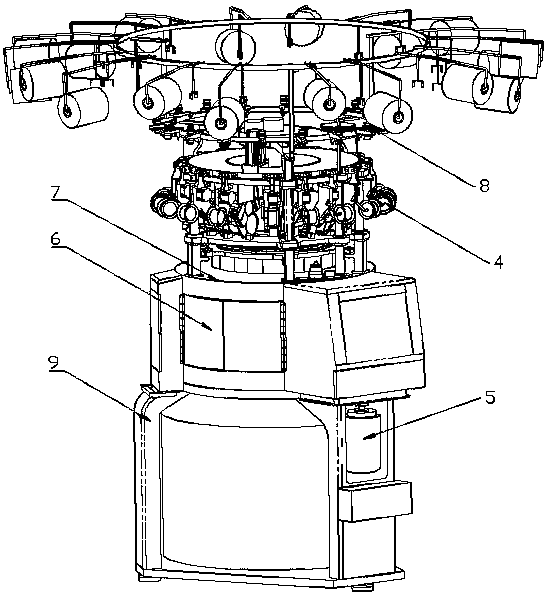

[0033] Please refer to figure 1 , a novel artificial fur knitting machine, comprising a fuselage 9, a yarn feeder 8, a carding device, a weaving device 7, a cloth rolling device 6, and a main control motor 5, and the main control motor 5 drives the yarn feeder 8 , the weaving device 7 and the cloth rolling device 6 work in motion.

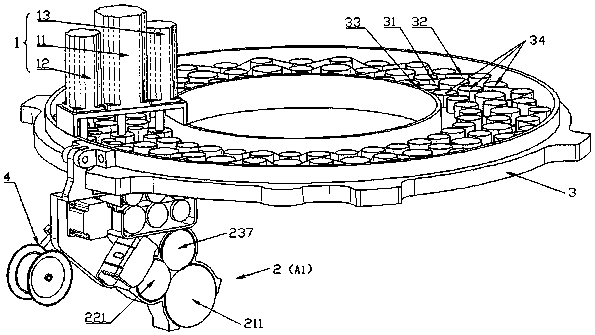

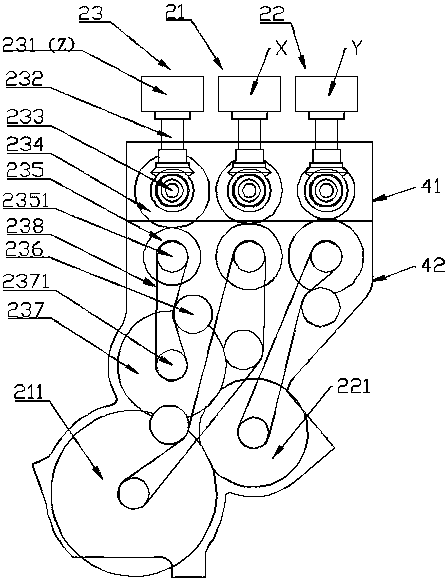

[0034] Please refer to figure 2 , the combing device includes a driving table 3 and several combing heads 2 connected to the driving table 3. Preferably, the working wheel sets in the several combing heads 2 have the same structure so as to move synchronously. In this implementation In example, the quantity of described comb head 2 is 18, but the quantity of comb head 2 of the present invention includes and is not limited to 18, can also be 12, 16, 21, 24 etc., only increase or decrease the number of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com