Thread sweeping device of electronic pattern sewing machine

A pattern machine and electronic technology, which is applied to thread hooks for sewing machines, sewing machine components, textiles and paper making, etc., can solve the problems of high production cost, difficult control, poor energy saving, etc., and achieves convenient assembly and maintenance, small space occupation, simplified The effect of the driver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

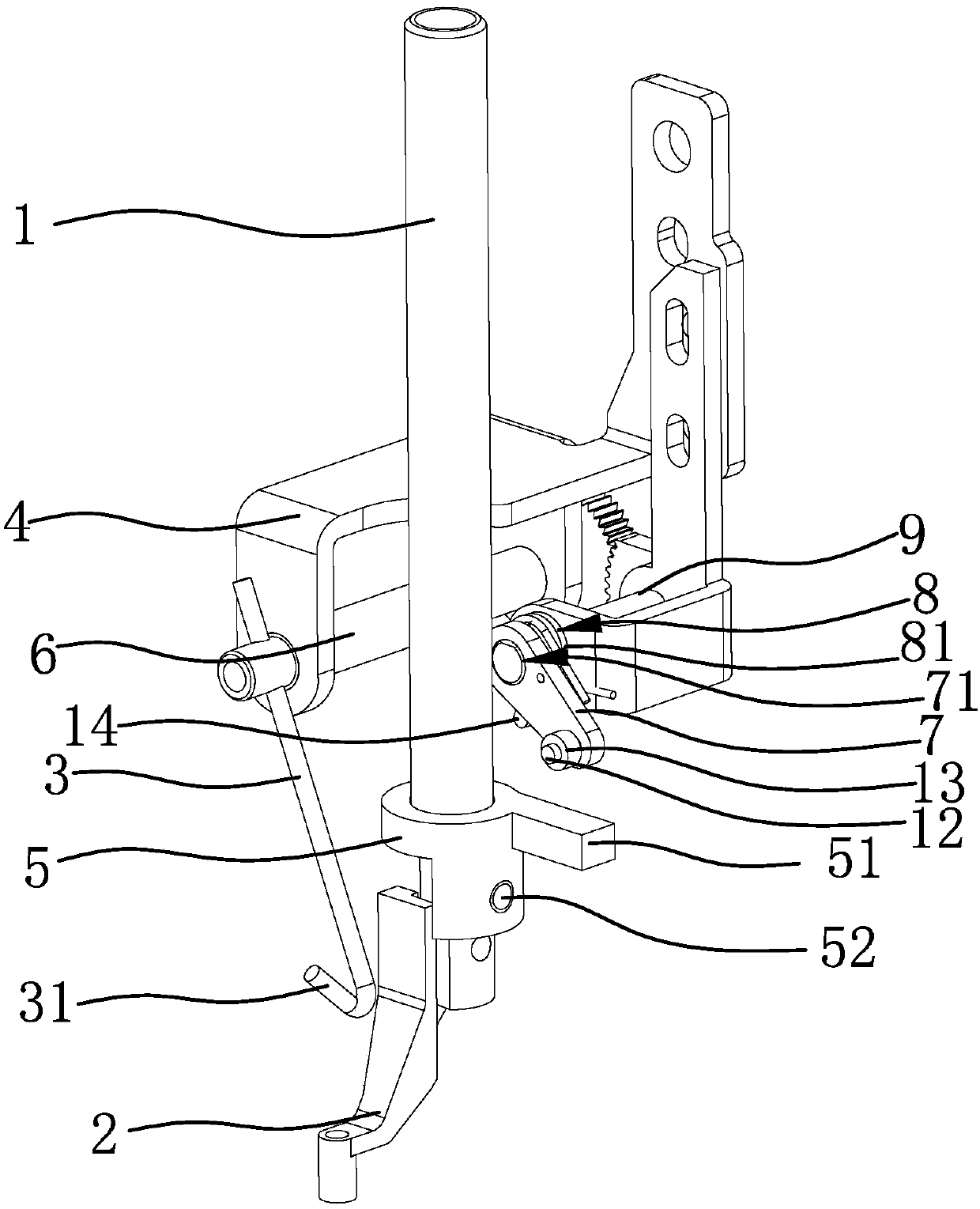

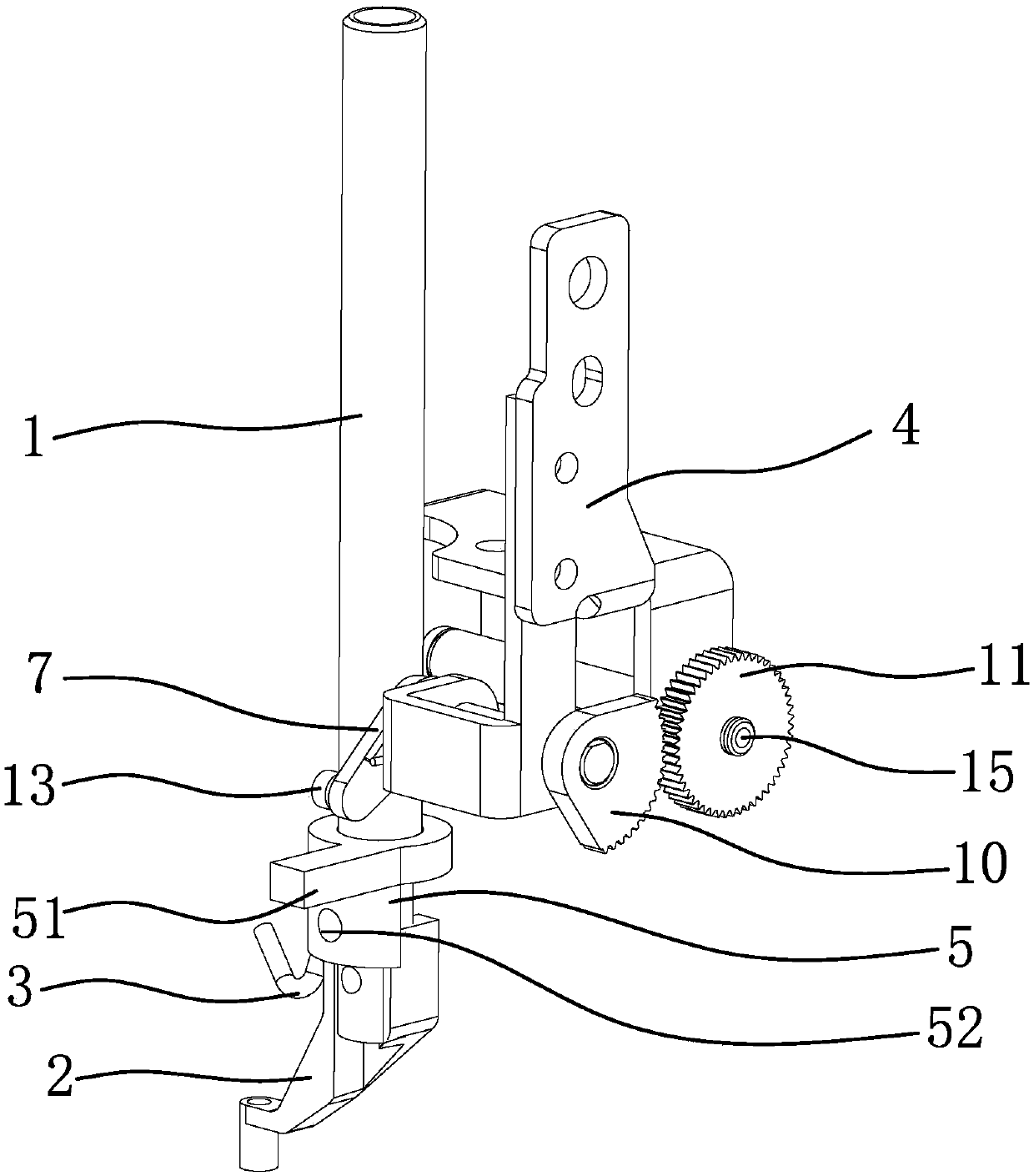

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0024] like figure 1 and figure 2 As shown, the electronic pattern machine includes a presser foot bar 1 capable of reciprocating up and down and a presser foot 2 arranged at the lower end of the presser foot bar 1 , and the thread sweeping device includes a thread sweeper bar 3 , a mounting frame 4 and a presser foot bar fixed on the presser foot bar 1 . The lifting block 5 is provided with a rotating shaft 6 and a swing arm 7 that can drive the rotating shaft 6 to reciprocate on the mounting frame 4. The swing arm 7 is located above the lifting block 5. 7 are in contact with each other and drive it to swing, one end of the thread sweeping rod 3 is connected to the rotating shaft 6, and the other end of the thread sweep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com