A two-way synchronous construction method for high-rise buildings

A two-way synchronization and construction method technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of long construction period of underground structures and affecting the construction period of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

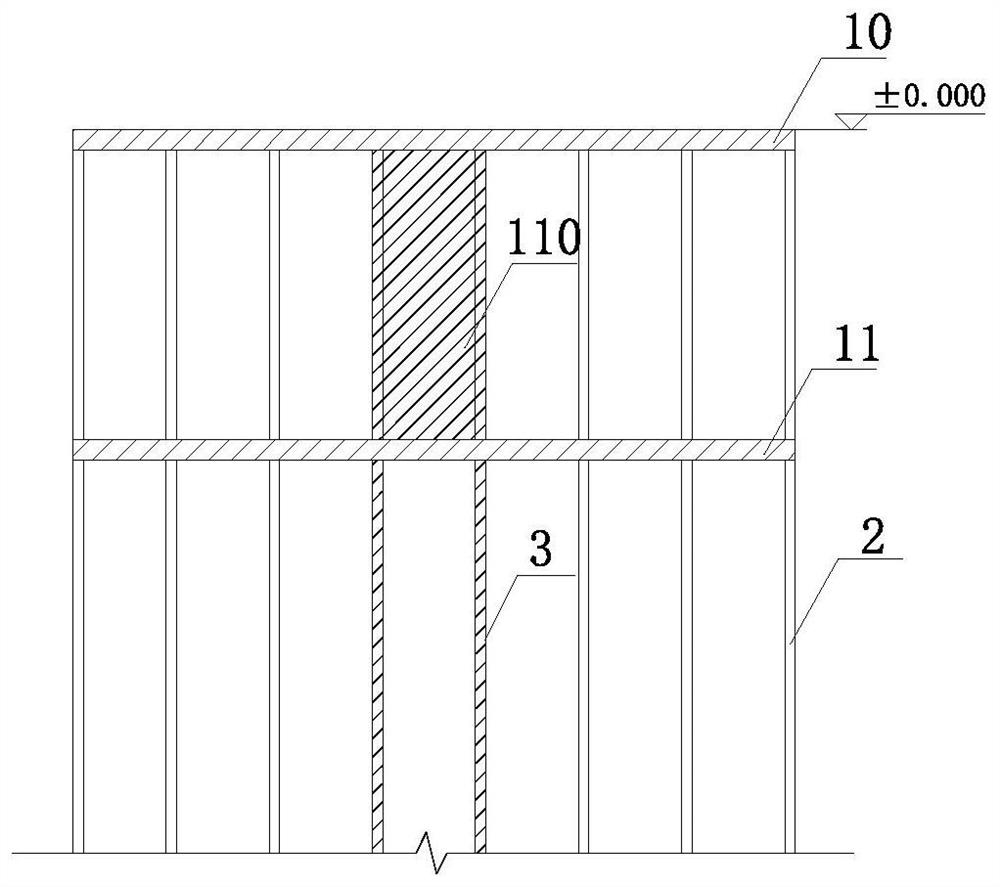

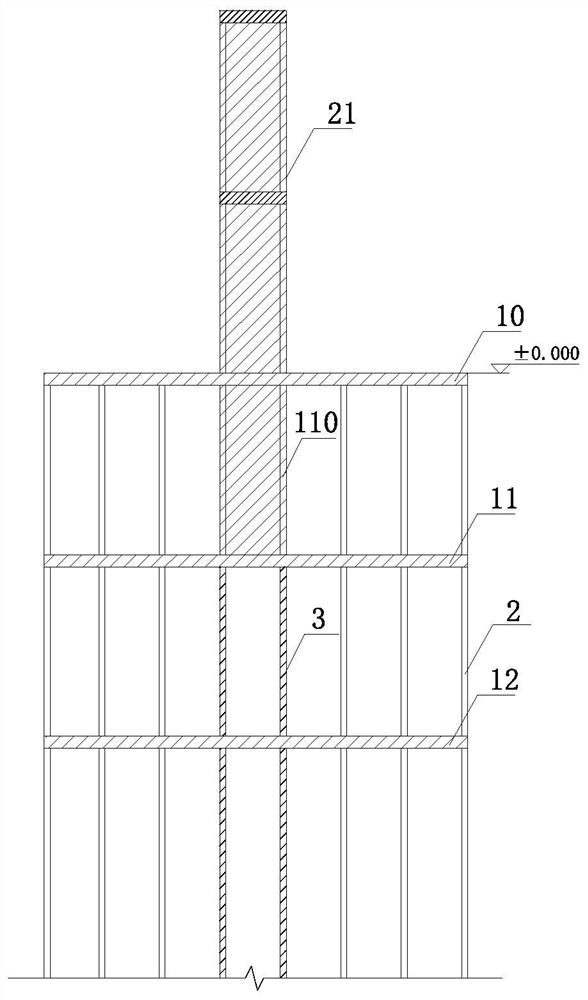

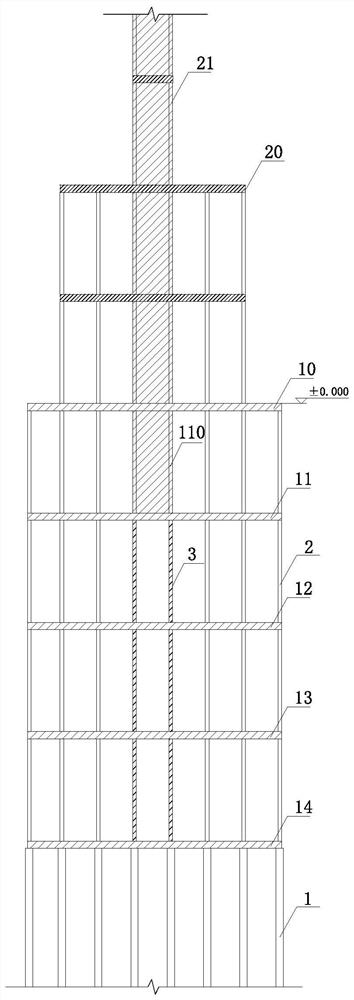

[0033] Combine 1 to Figure 4 As shown, the high-rise building two-way synchronous construction method provided by the present embodiment includes the following steps:

[0034] In the first step, the cast-in-place pile 1 is constructed to form foundation engineering piles, and the steel column 2 of the building structure is inserted into the pile foundation, and the steel column 2 at the shear wall of the core tube and the cast-in-situ pile 1 below are densified to form an effective vertical force transmission system. Wherein, the steel column 2 may be a steel column, a steel tube column or a steel tube concrete column. Due to the two-way simultaneous construction of high-rise buildings and the construction of the basement, the above-ground core tube is constructed simultaneously, and the core tube shear wall is not suitable for simultaneous construction with the basement due to the construction process from bottom to top. In order to effectively transfer the stress of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com