Wall dismantling device

A wall and mounting plate technology, applied in building maintenance, construction, building construction, etc., can solve the problems of personal injury, difficulty in improving the efficiency of wall demolition, high labor cost, etc., to improve efficiency, easy operation, and improve demolition The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

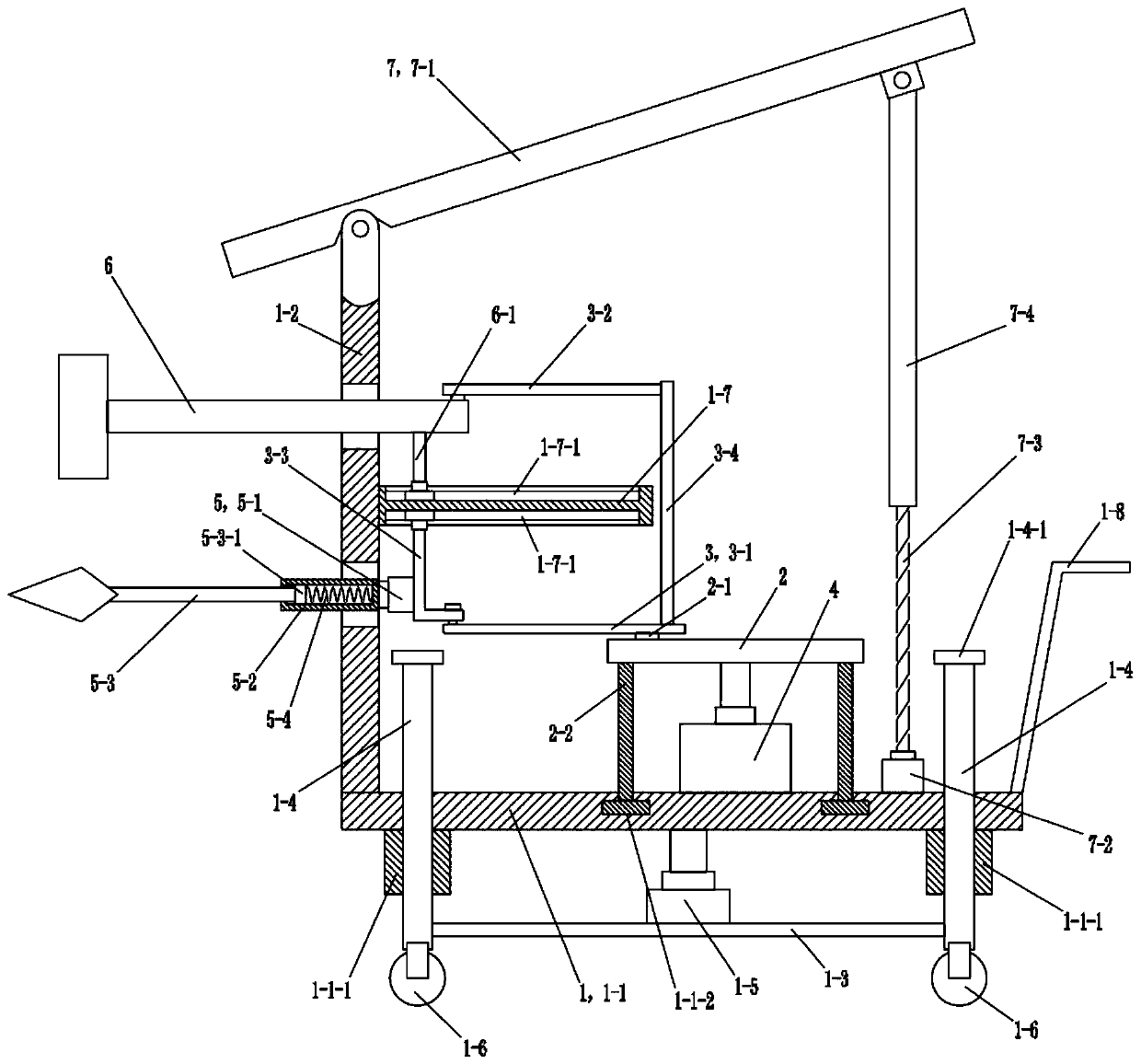

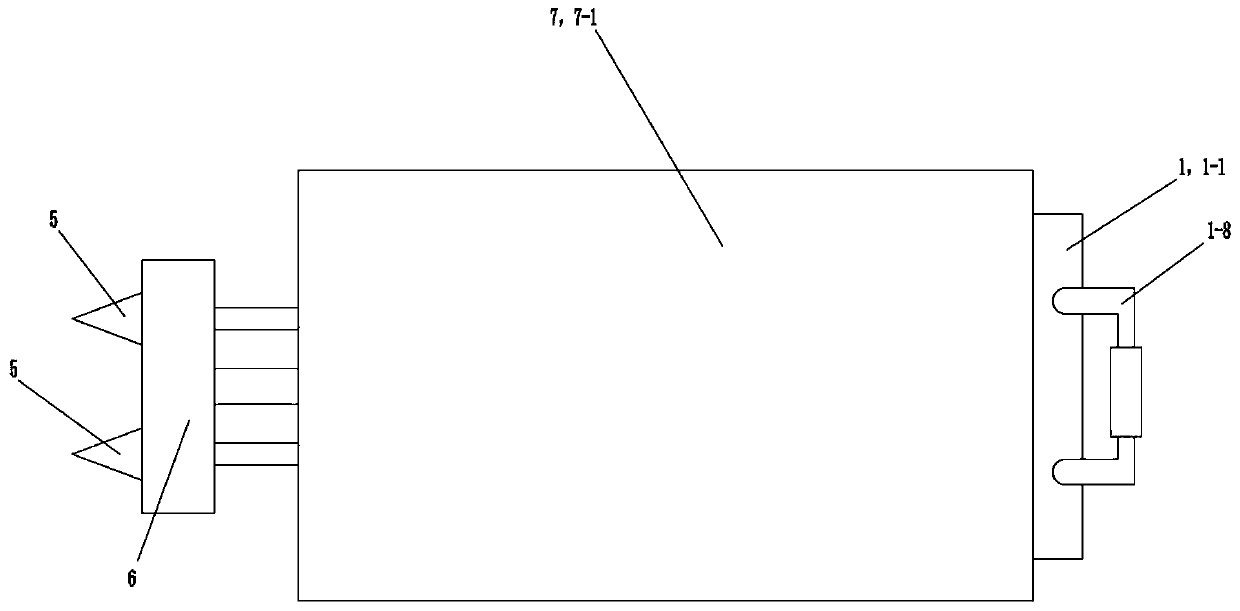

[0030] See figure 1 and figure 2 , The wall removal device of this embodiment includes a vehicle frame 1 , a drive plate 2 , a linkage frame 3 , a drive motor 4 , a drill assembly 5 , an impact hammer 6 and a baffle assembly 7 . Both the drill assembly 5 and the impact hammer 6 are located at the front of the vehicle frame 1 . The driving motor 4 is arranged on the vehicle frame 1 , and the driving shaft of the driving motor 4 is connected with the driving plate 2 . The driving disc 2 is rotatably connected with the linkage frame 3 . The linkage frame 3 is connected with the drill bit assembly 5 and the rear end of the percussion hammer 6 . The baffle assembly 7 includes a baffle 7-1 and a jacking assembly. The baffle plate 7-1 is located above the vehicle frame 1. The jacking assembly drives the rear portion of the baffle plate 7-1 to move upward.

[0031] The vehicle frame 1 includes a chassis 1-1, a mounting plate 1-2, a base plate 1-3, a column 1-4 and a lifting cyl...

Embodiment 2

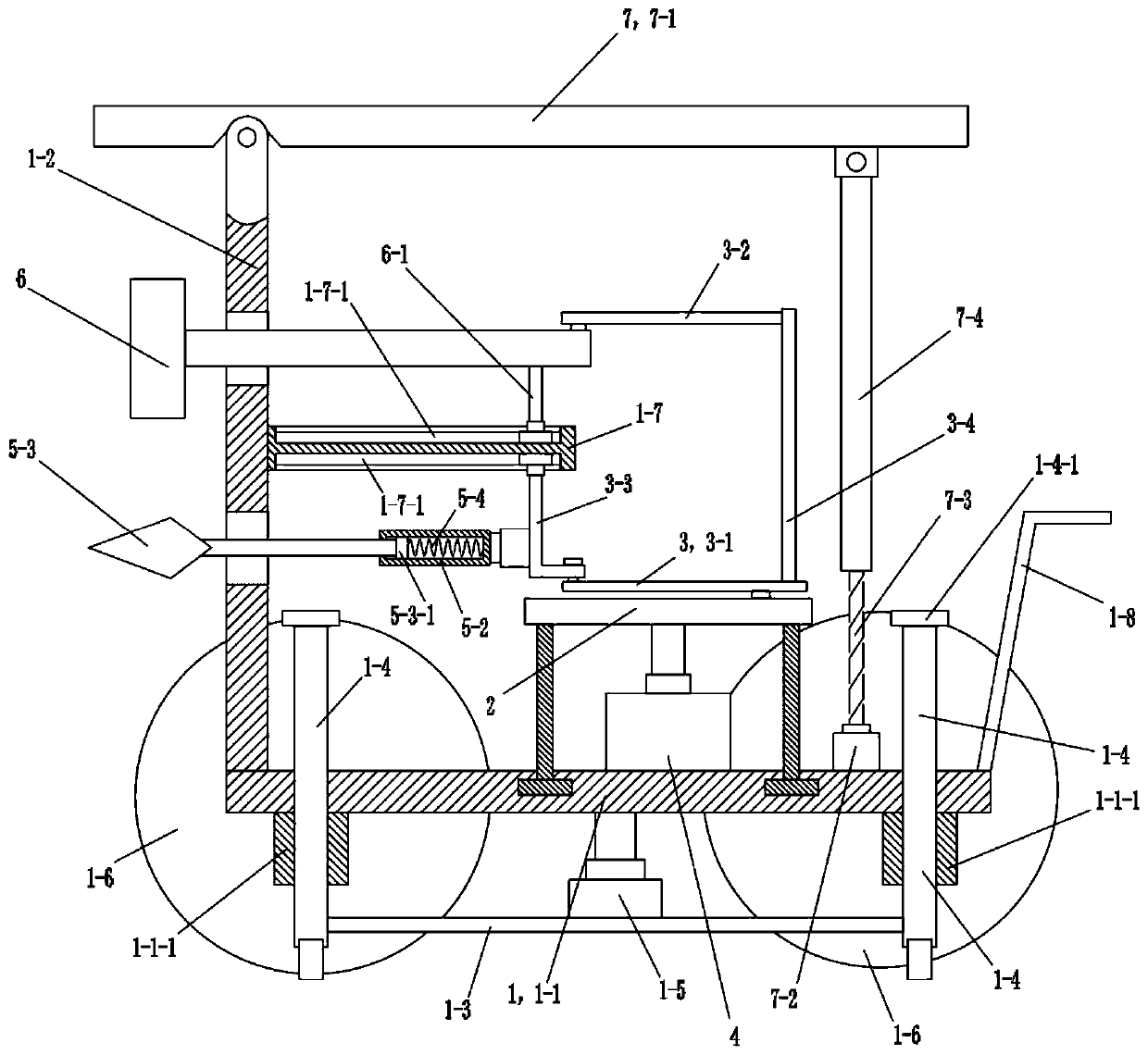

[0041] See image 3 , this embodiment is basically the same as Embodiment 1, the difference is:

[0042] The front portion of the chassis 1-1 of the vehicle frame 1 is provided with wheels 1-6. The radius value of the wheel 1-6 is greater than the minimum distance value between the bottom end of the column 1-4 and the chassis 1-1.

[0043] During use, the lifting cylinder 1-5 drives the chassis 1-1 to move upward, so that each column 1-4 extends downward to support the ground, and the wheels 1-6 are suspended in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com