Pasture processing device for animal husbandry breeding

A treatment device and animal husbandry technology, applied in the field of animal husbandry, can solve the problems of large drying heat loss, time-consuming forage, and slow drying speed, etc., to achieve the effects of reducing heat loss, increasing convenience, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

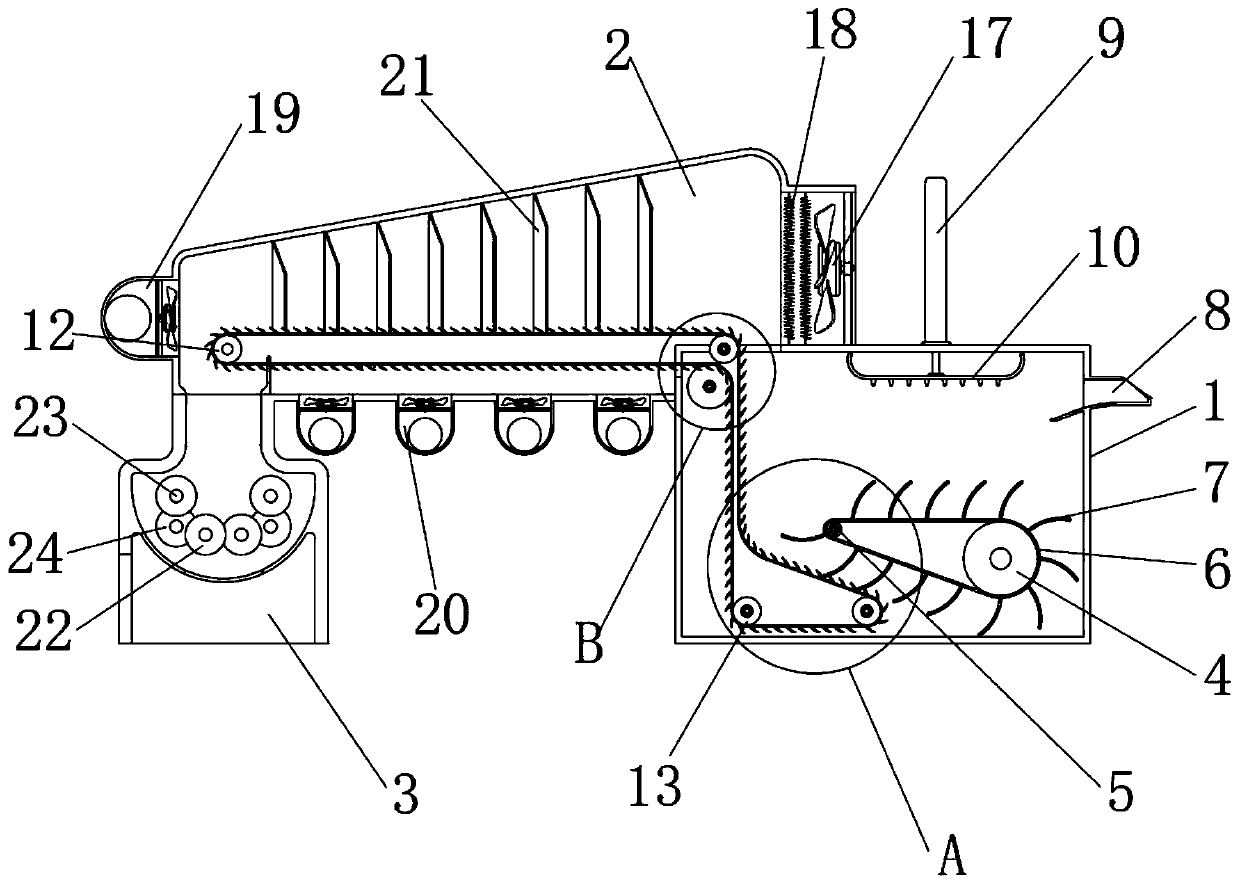

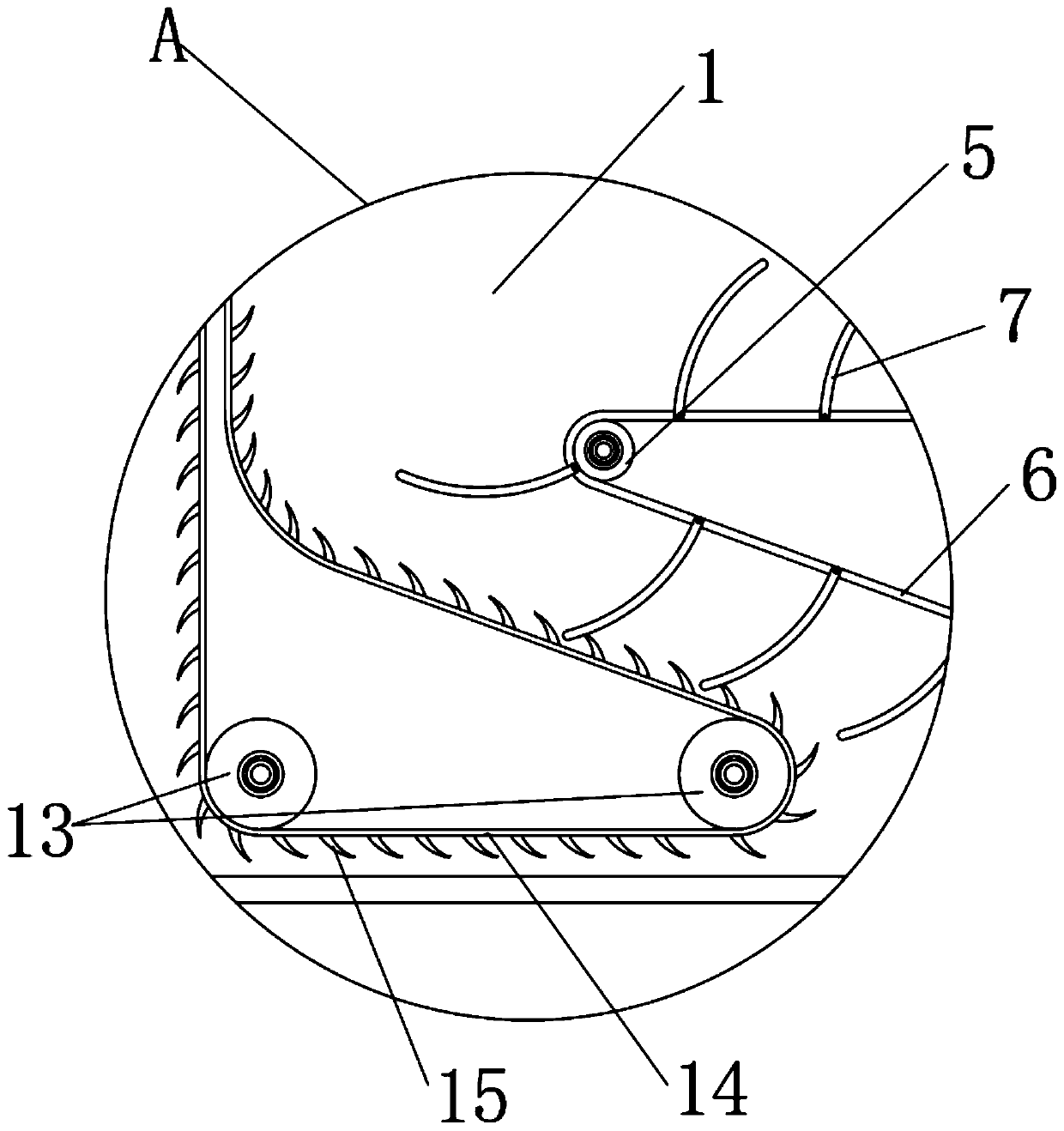

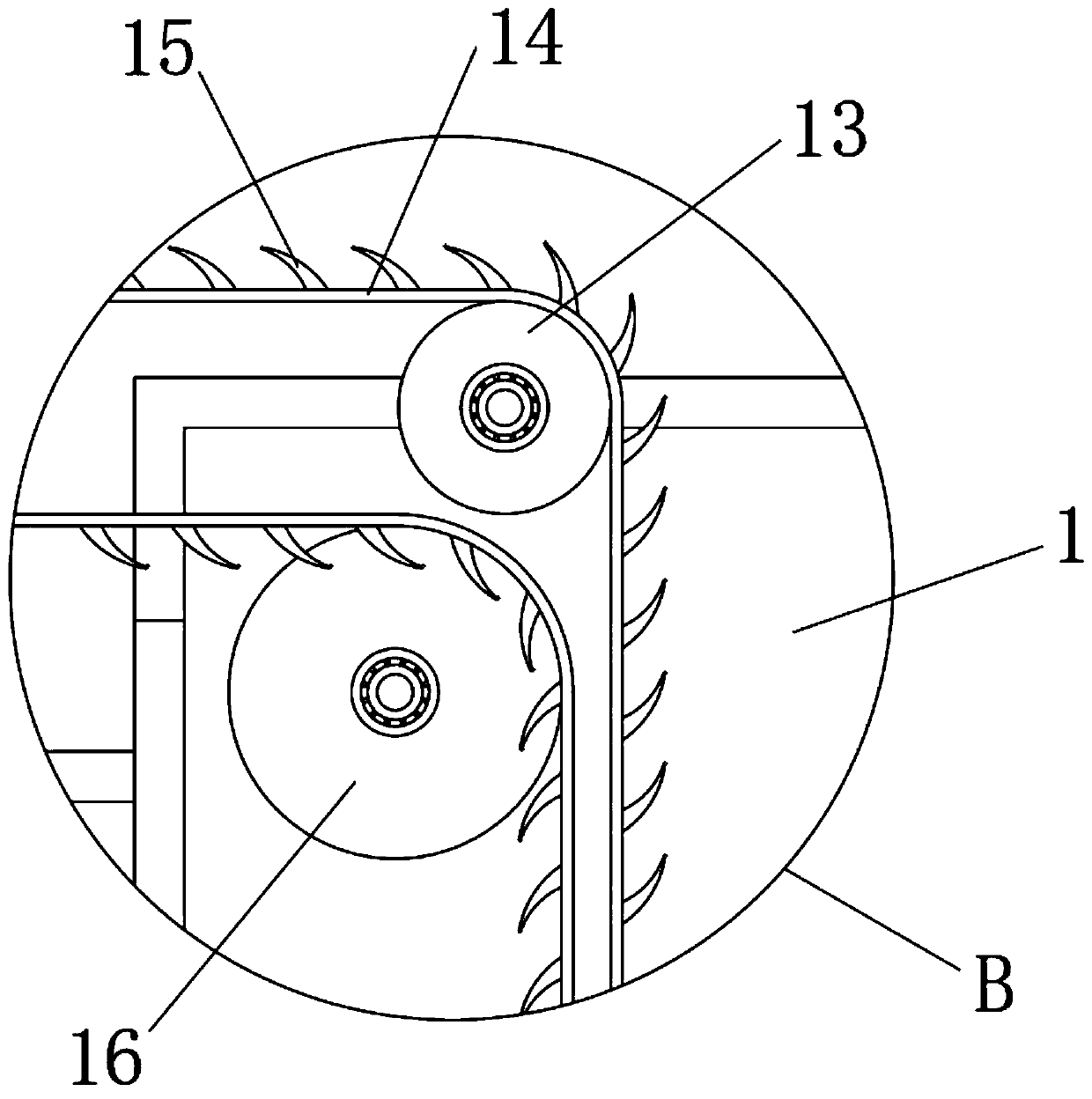

[0030] The invention provides a pasture processing device for animal husbandry, see the attached figure 1 As shown, it includes a cleaning pool 1, a drying box 2 and a pulverizer 3, the pulverizer 3 is installed on one side of the cleaning pool 1, one end of the drying box 2 is installed above the pulverizer 3, and the other end of the drying box 2 Installed above the cleaning tank 1, the inside of the cleaning tank 1 is provided with a first driving roller 4 and a driven roller 5, and the outside of the first driving roller 4 and the driven roller 5 is sleeved with a first transmission belt 6, the first transmission The outer surface of the belt 6 is fixed with a toggle lever 7, refer to the attached figure 1 And attached Figure 6 As shown, the upper surface of the cleaning tank 1 is equipped with a hydraulic cylinder 9 through bolts, the output shaft of the hydraulic cylinder 9 runs through the cleaning tank 1 and is equipped with a pressure rod 10, and through the first d...

Embodiment 2

[0041] The invention provides a pasture processing device for animal husbandry, see the attached figure 1 And attached Figure 7 As shown, it includes a cleaning pool 1, a drying box 2 and a pulverizer 3, the pulverizer 3 is installed on one side of the cleaning pool 1, one end of the drying box 2 is installed above the pulverizer 3, and the other end of the drying box 2 Installed above the cleaning tank 1, the inside of the cleaning tank 1 is provided with a first driving roller 4 and a driven roller 5, and the outside of the first driving roller 4 and the driven roller 5 is sleeved with a first transmission belt 6, the first transmission The outer surface of the belt 6 is fixed with a toggle lever 7, refer to the attached figure 1 , attached Figure 6 And attached Figure 7 As shown, the upper surface of the cleaning tank 1 is equipped with a hydraulic cylinder 9 through bolts, the output shaft of the hydraulic cylinder 9 runs through the cleaning tank 1 and is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com