Composite spinneret for small-specification wire rod and manufacturing method thereof

A technology of laying tube and small size, which is used in the direction of manufacturing tools, rod connection, metal rolling, etc. Large and other problems, to achieve the effect of guaranteed service life, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

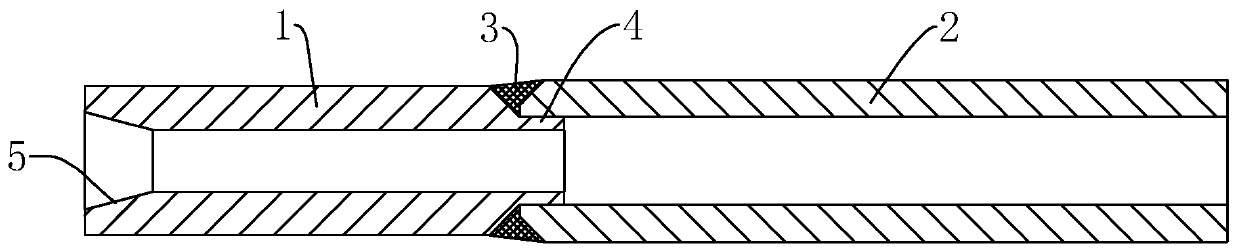

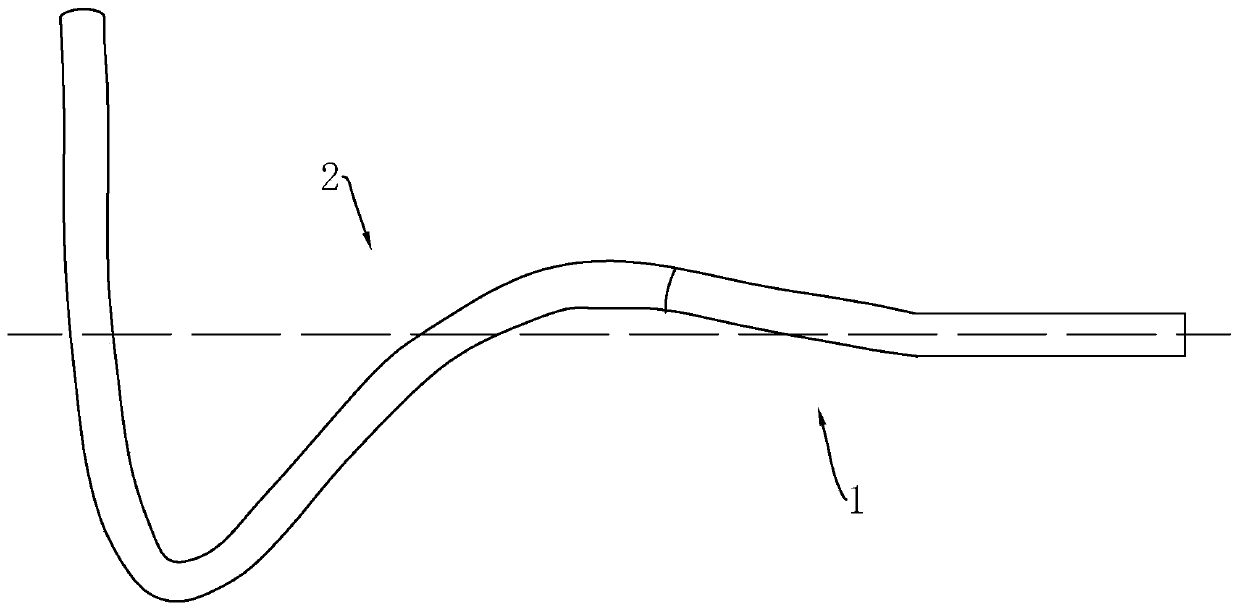

[0034] Example: A composite spinning tube used for small gauge wire, such as figure 1 As shown, it includes a tubular reinforced section 1 and a conventional section 2. The axial length of the reinforced section 1 is 975-1000mm, the outer diameter is φ50.5mm, and the inner diameter is φ33.7mm; the axial length of the conventional section 2 is 2800mm , The outer diameter is φ51mm, and the inner diameter is 38.4mm. The output end of the reinforced section 1 is formed with a connecting portion 4 extending along the axis. The connecting portion 4 is a tubular structure with a length of 20mm. Its inner diameter is the same as the inner diameter of the reinforced section 1, and the outer diameter is the same as the inner diameter of the conventional section 2. The connecting portion 4 can be stably inside It is embedded in the input end of the conventional section 2 to realize the pre-fixation of the reinforced section 1 and the conventional section 2.

[0035] Both the output end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com