Design method of micro perforated plate sound absorption body with maximized average sound absorption coefficient

A sound absorption coefficient and micro-perforated plate technology, which is applied in the direction of sound-generating devices and instruments, can solve problems such as difficult design ideas to achieve noise reduction optimization, and achieve the effects of reducing the quality of life, good application prospects, and strong comprehensive noise reduction capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

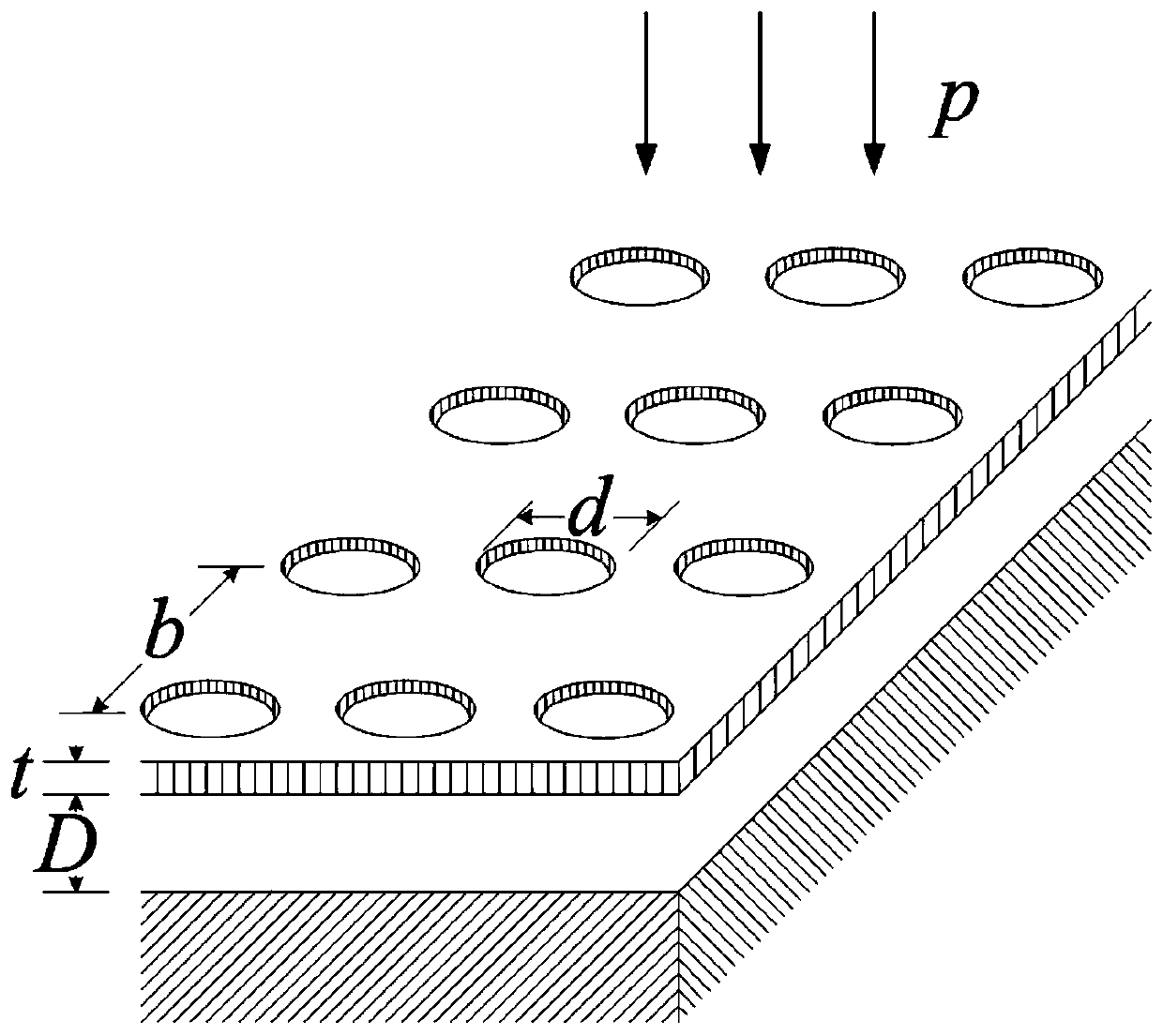

[0051] figure 1 is the structural diagram of the micro-perforated sound absorbing body, d, t, p, D and b respectively represent the diameter of the perforation, the thickness of the plate, the percentage of the total area of the perforation in the whole plate, the thickness of the cavity behind the plate and the distance between the hole centers, because d, p and b exist relationship, so as long as two of these three variables are determined, the remaining one is determined. Here, d, t, p and D are selected as design variables, and the goal is to maximize the impact of the micro-perforated plate sound absorbing body on the entire The average sound absorption coefficient of the frequency band;

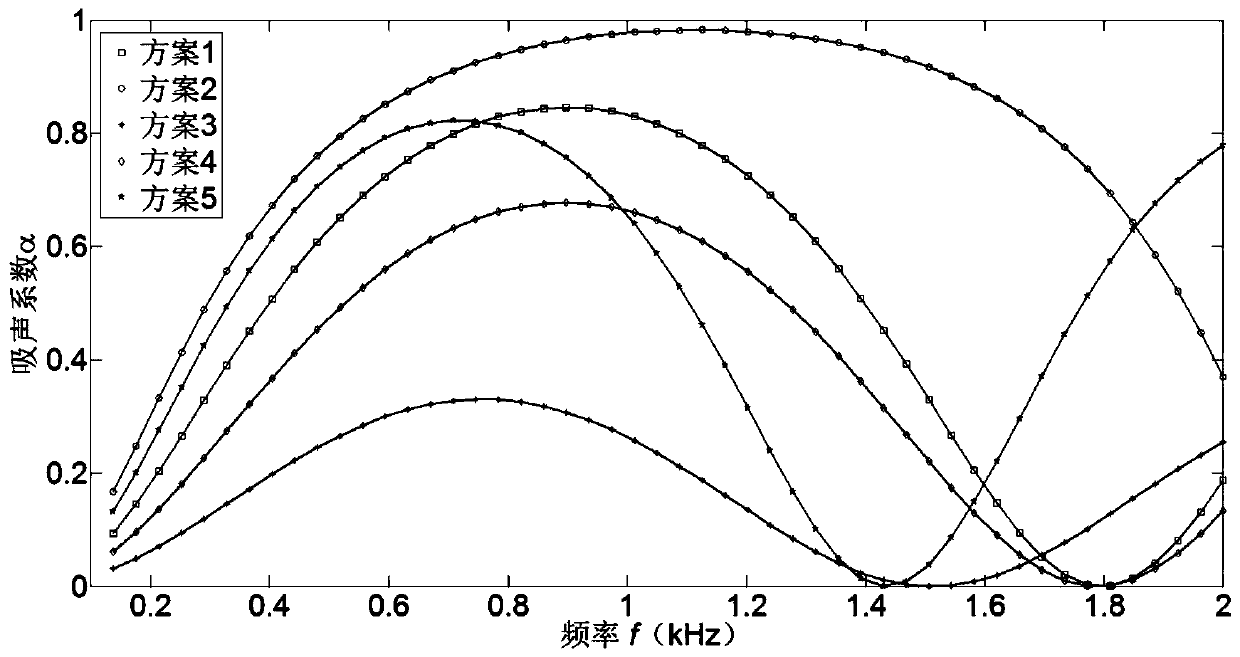

[0052] figure 2 Five frequency-absorption coefficient curves are shown, each representing a microperforated absorber design based on randomly generated solution vectors. Because the solution vector is randomly generated within the domain of definition, the five groups of solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com