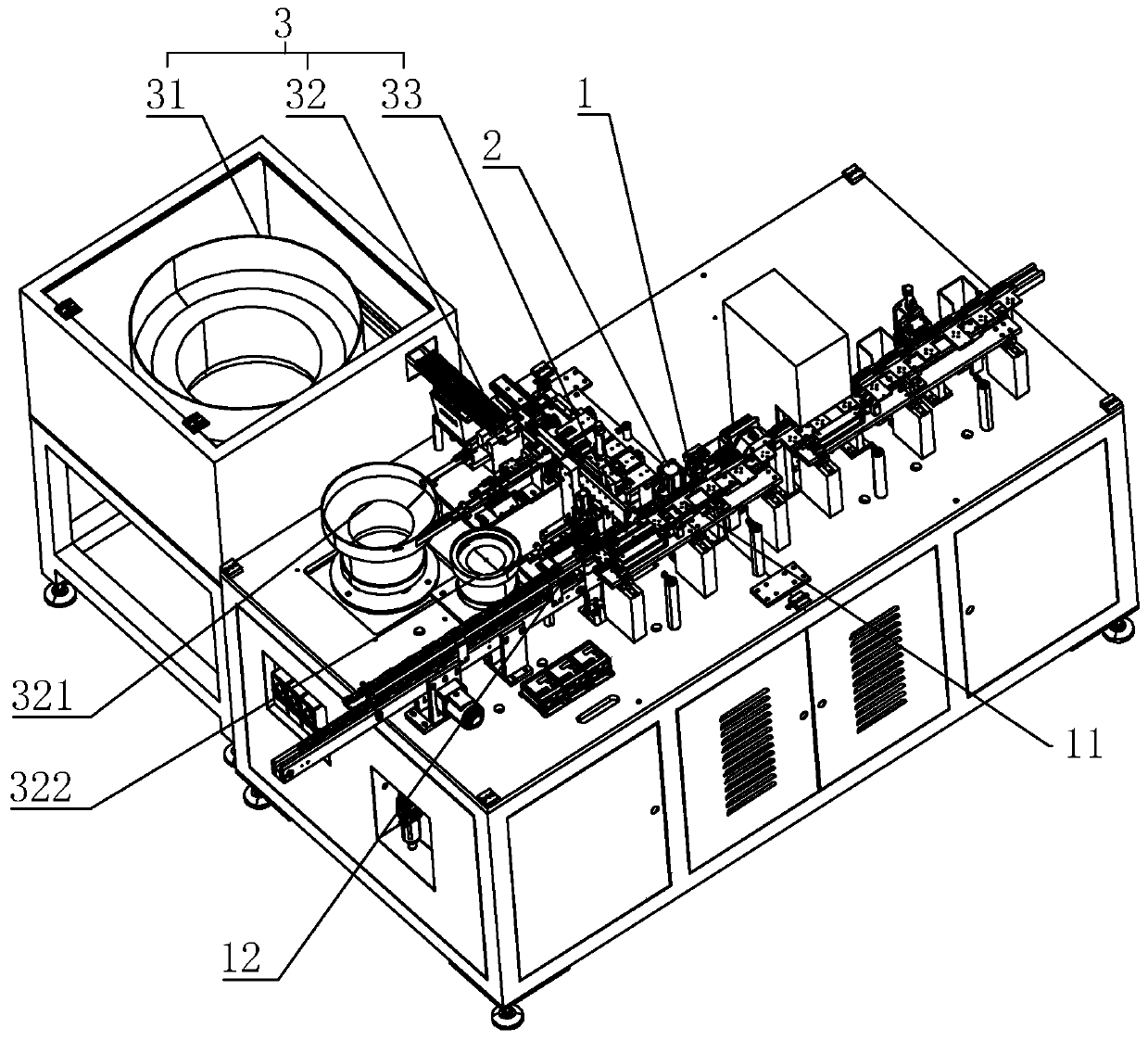

Relay base cover mounting device

A relay and cover feeding technology, applied in relays, circuits, electrical components, etc., can solve the problems of prone to misalignment, low placement efficiency, and reduced relay base capping efficiency, so as to reduce the probability of misplacement and increase placement efficiency. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

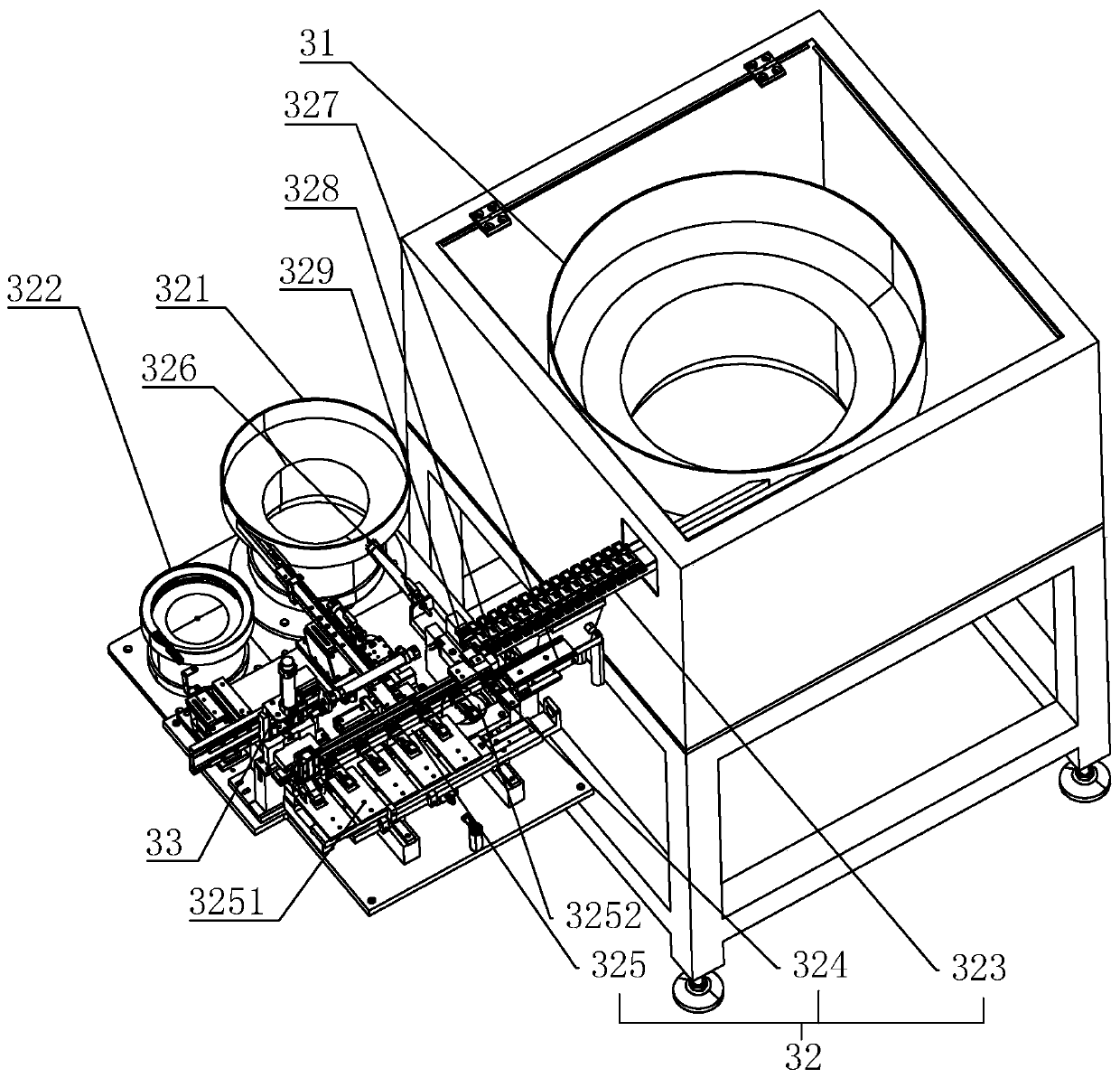

Examples

Embodiment approach

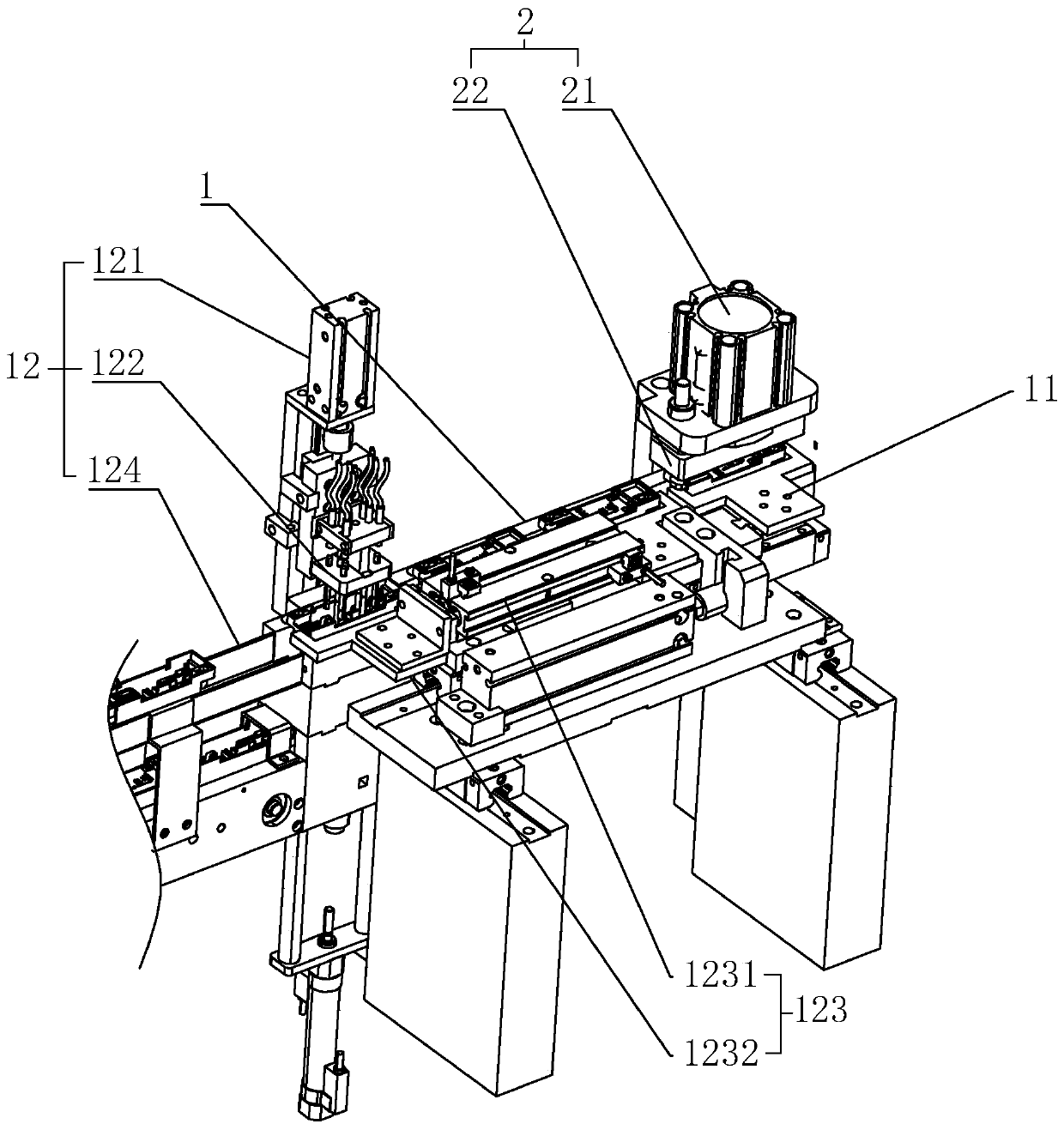

[0028] As an improved specific implementation, the detection and waste discharge mechanism 12 includes a detection cylinder 121, a detection head 122, a waste discharge assembly 123 communicating with the detection head 122, and a waste discharge track 124. One end of the waste discharge track 124 is connected to The ends of the transmission track 1 are connected, the detection cylinder 121 is fixed above the end of the waste discharge track 124 opposite to the transmission track 1, the detection head 122 is fixed on the push rod of the detection cylinder 121, and pushed by the detection cylinder 121, it extends into the Detect the assembled terminals in the casing, and output a signal to the waste discharge assembly 123 when the detection result is unqualified, the waste discharge assembly 123 pushes the current casing into the waste discharge track 124, through the cooperation of the detection head 122 and the detection cylinder 121 function, it can simply and effectively det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com