Pressure grinding type gravel making machine

A sand making machine and grinding disc technology, which is applied in the field of mining machinery and equipment, can solve problems such as the inability to adjust the gap between the pressure roller and the grinding disc, and the inability to produce gravel, so as to reduce operating noise and production costs, improve the quality of gravel, and ensure equipment operation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

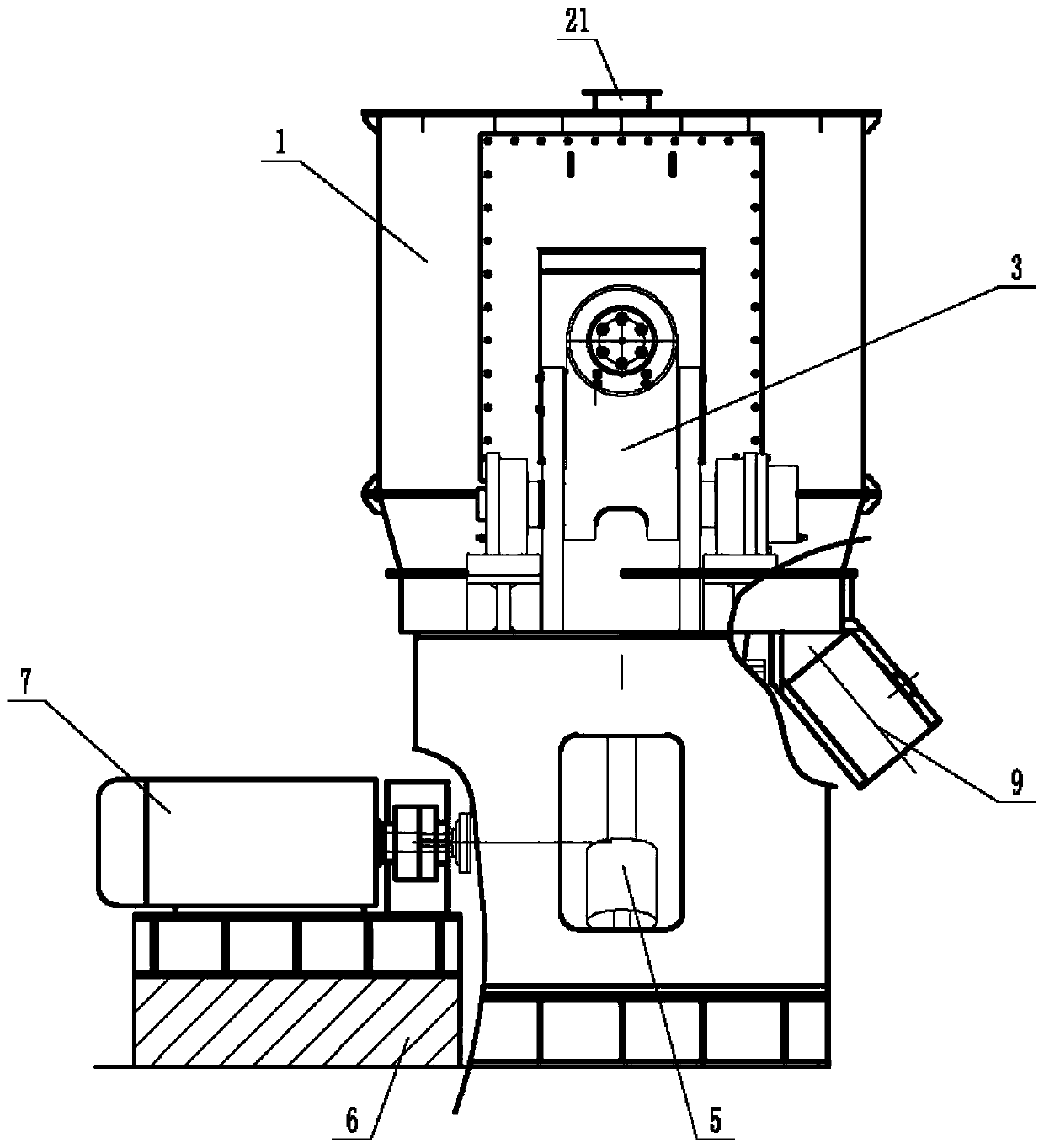

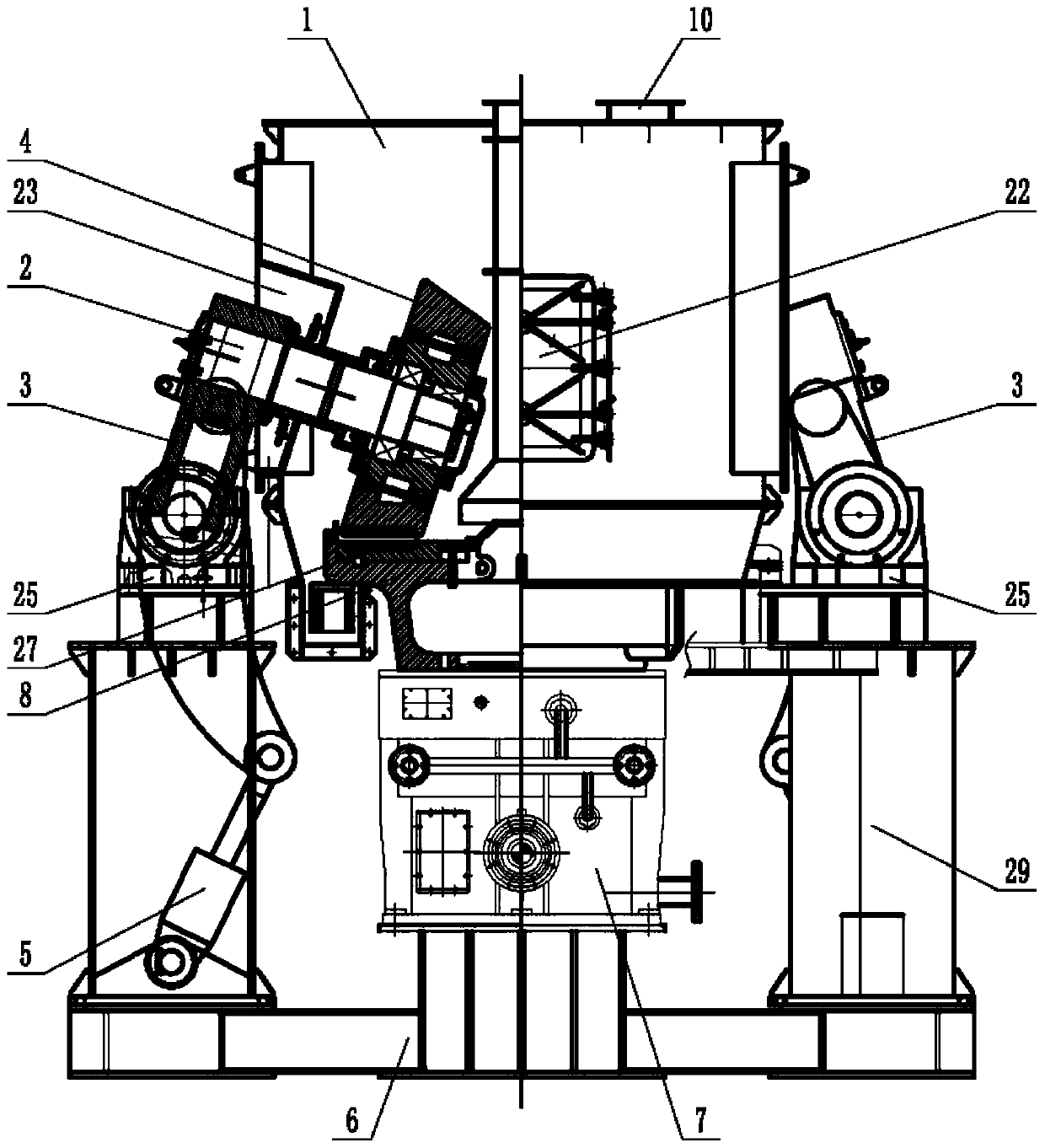

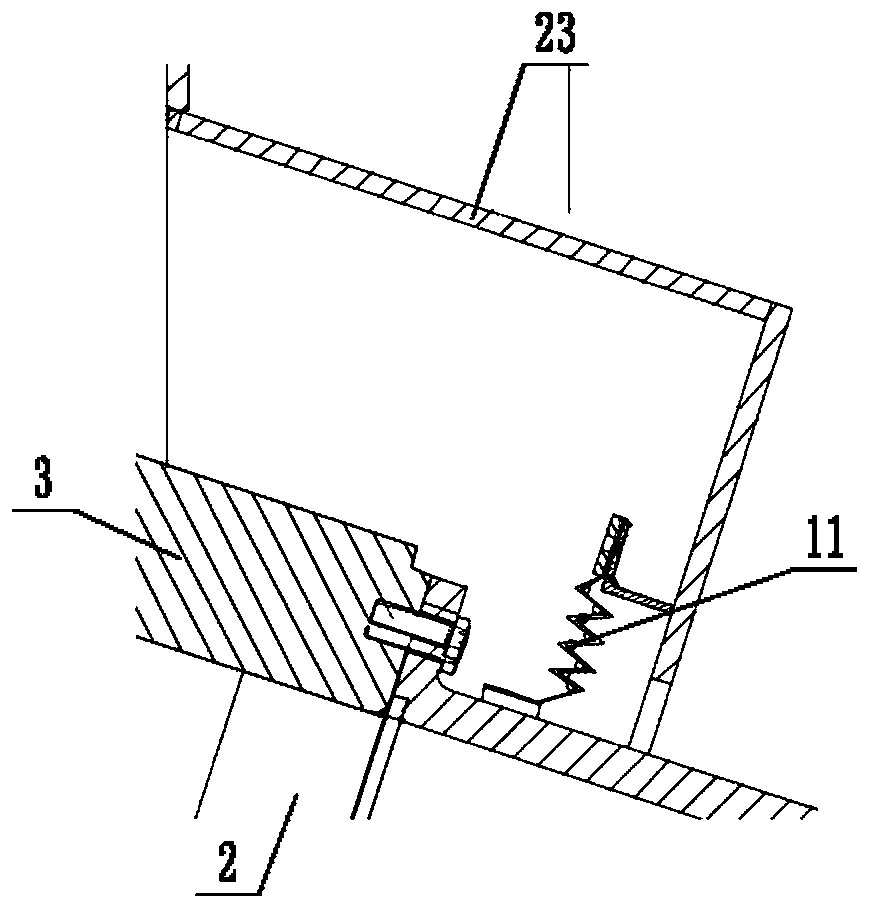

[0019] Such as Figures 1 to 4 As shown, a disc-type sand making machine includes a base 6 on which an adjusting oil cylinder 5, a geared motor assembly 7 and a bracket 29 are mounted, on which a housing 1 and at least one mounting seat 25 are installed, and the housing 1 is provided with an inlet 21 on the top, an outlet 9 on its bottom, at least one opening 23 on its side, and a grinding disc 14 installed inside. The central axis of the grinding disc 14 is perpendicular to the base 6. 7 drives the grinding disc 14 to rotate around its central axis, and a rotating arm 3 is installed on the mounting base 25. The axis of rotation of the rotating arm 3 is parallel to the base 6, and one end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap