Electric rotating lifting swing lifting rod

An electric rotating and boom technology, applied in the direction of load hanging components, entertainment, stage installations, etc., can solve the problems of waste of hanging points, poor stage effect, inability to realize multi-angle rotation, lift and swing of hanging points, etc., to achieve convenient configuration. Installation work, compact structure, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

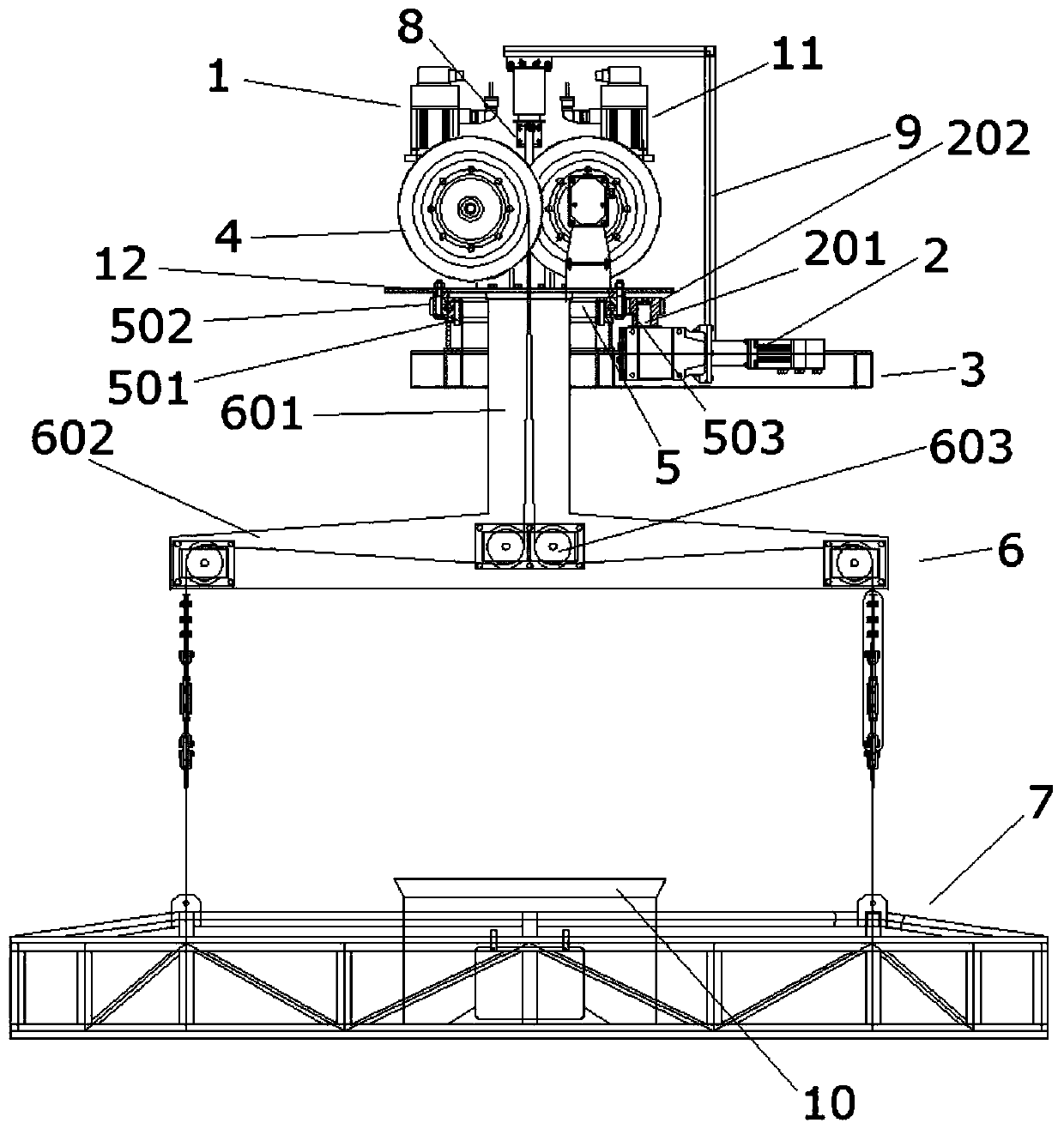

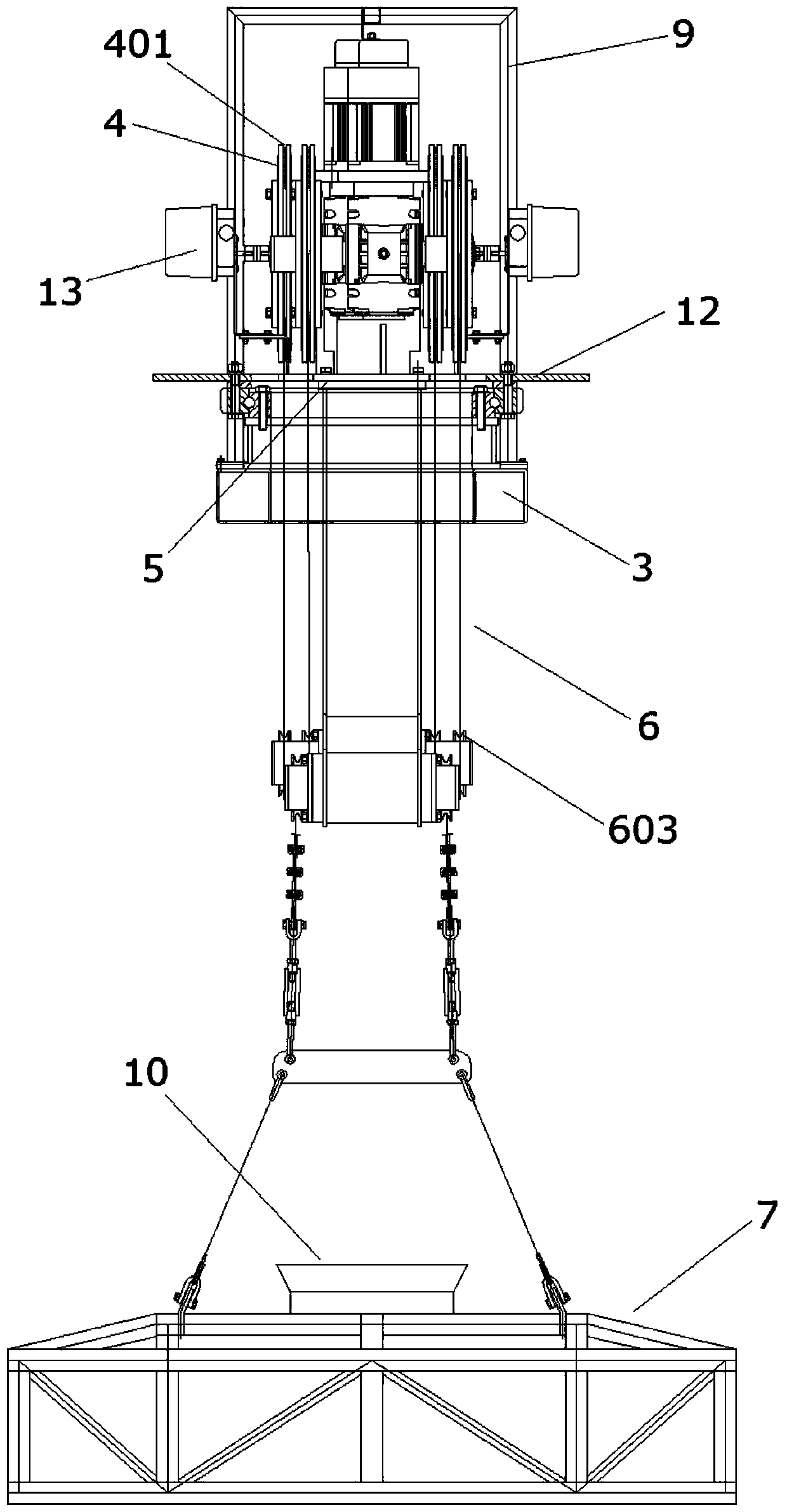

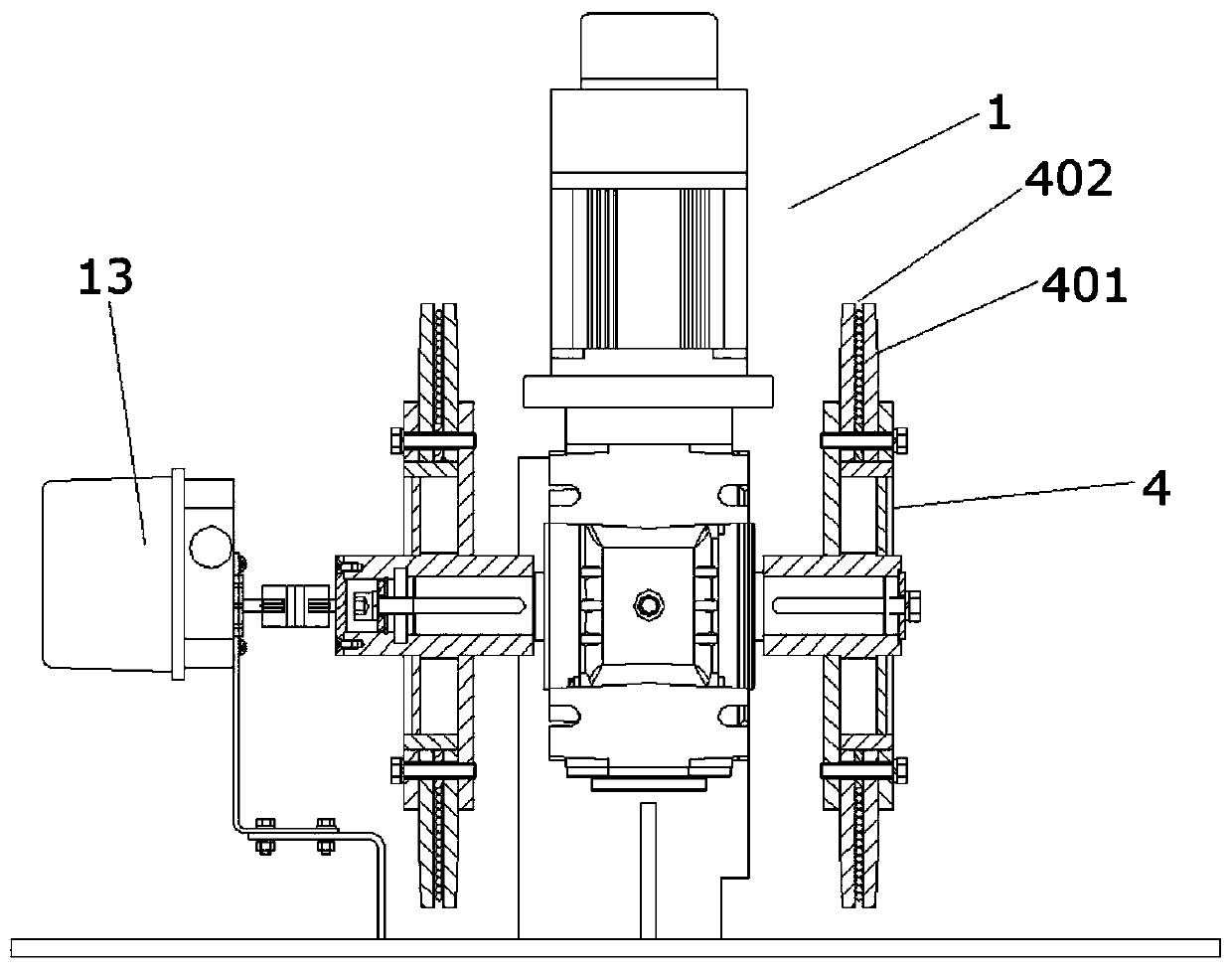

[0028] Such as figure 1 , 6 As shown, it is the electric rotary lifting and swinging boom of the present invention, which includes a rotating motor 2 and a base 3. The rotating motor 2 is connected to a slewing support 5, and a T-shaped beam assembly 6 is fixedly connected to the slewing support 5. The bottom of the T-beam assembly 6 is connected with a boom assembly 7, and the boom assembly 7 is provided with a plurality of suspension points for installing stage equipment; the base 3 is located below the slewing support 5, and includes at least Two lifting motors, that is, the first lifting motor 1 and the second lifting motor 11, each lifting motor is hoisted with different lifting points, and the at least two lifting motors are independent of each other; the rotating motor 2 is installed on the base 3 and placed horizontally.

[0029] The slewing support 5 of this embodiment has an inner ring 501 and an outer ring 502, and the slewing support 5 is fixed on the base 3 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com