Compounded diesel pour point depressant, and preparation method and application thereof

A diesel pour point depressant and technology of pour point depressant, which are used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of unsatisfactory diesel fluidity improvement effect and limited pour point depressant effect, and improve the pour point depressant effect. , Improve low temperature flow performance, overcome the effect of poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A composite diesel pour point depressant containing polar nitrogen-containing compounds, comprising the following components and contents in parts by weight:

[0036] 30 parts of ethanolamine,

[0037] 30 parts of triethanolamine,

[0038] Myristyl methacrylate-N-vinylimidazole pour point depressant 40 parts.

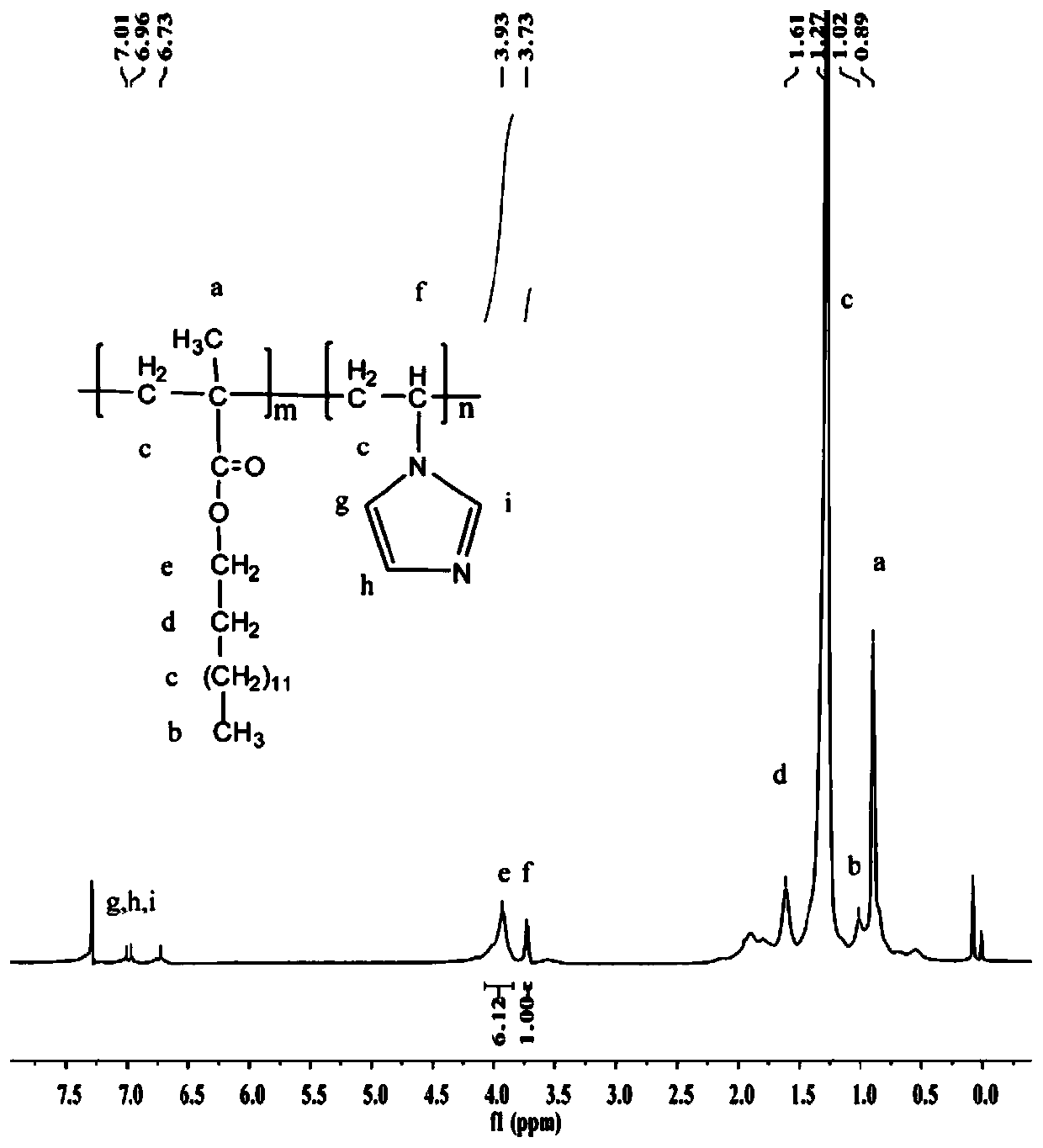

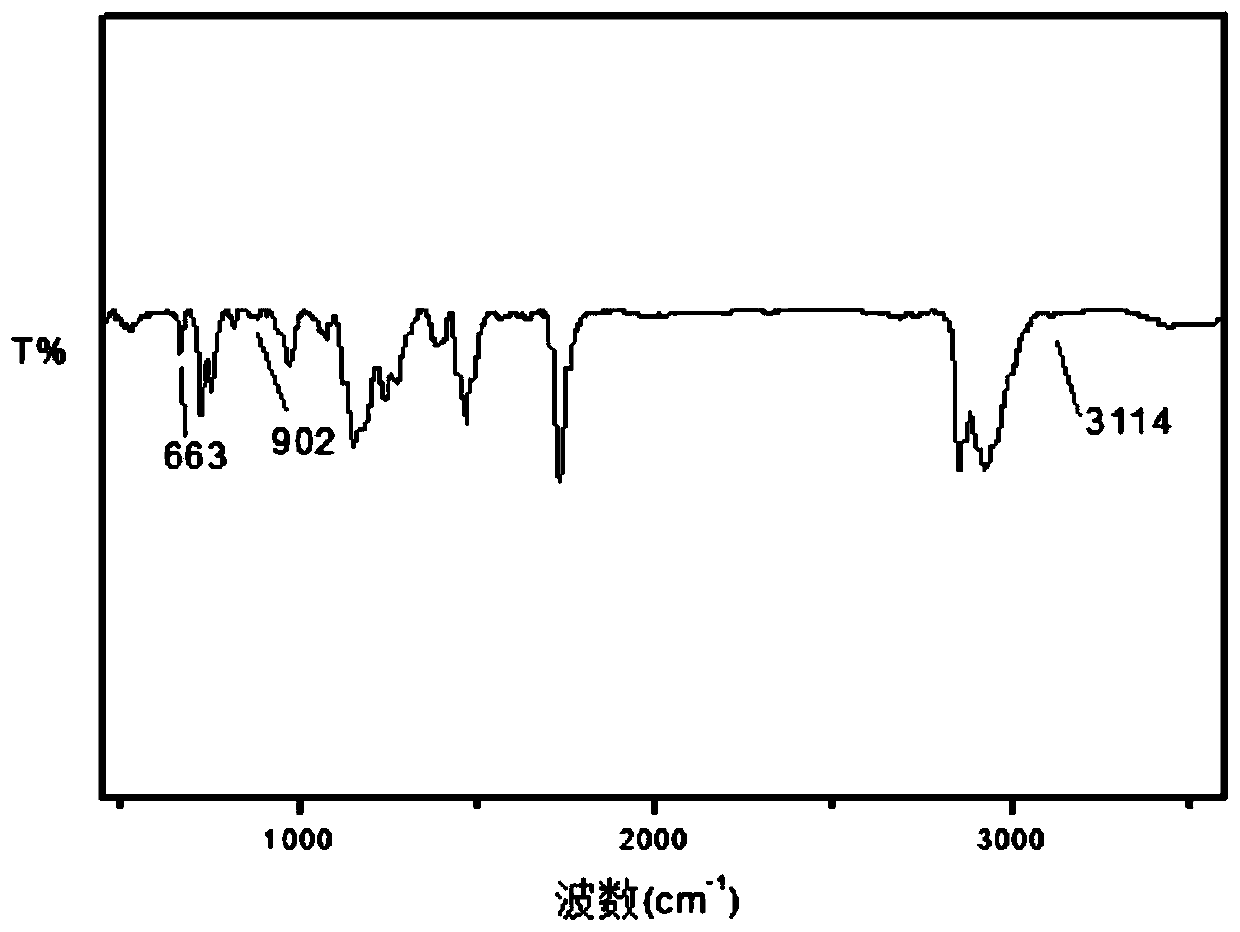

[0039] Wherein, the preparation method of myristyl methacrylate-N-vinylimidazole pour point depressant is: after myristyl methacrylate and N-vinylimidazole are mixed in a mol ratio of 3:1, join in toluene solvent, Under the condition that 0.9% of the total mass of reactants is benzoyl peroxide as an initiator, the reaction is carried out at 120°C for 9 hours, and the tetradecyl methacrylate-N-vinylimidazole pour point depressant is used. The tetradecyl methacrylate-N-vinylimidazole pour point depressant that obtains is carried out NMR and infrared characterization, the result is respectively as follows figure 1 , figure 2 shown. Depend on figure 1 It can b...

Embodiment 2

[0043] A composite diesel pour point depressant containing polar nitrogen-containing compounds, comprising the following components and contents in parts by weight:

[0044] 10 parts of ethanolamine,

[0045] 30 parts of triethanolamine,

[0046] 60 parts of myristyl methacrylate-N-vinylimidazole pour point depressant.

[0047] Wherein, the preparation method of myristyl methacrylate-N-vinylimidazole pour point depressant is: after myristyl methacrylate and N-vinylimidazole are mixed in a mol ratio of 3:1, join in toluene solvent, Under the condition that 0.9% of the total mass of reactants is benzoyl peroxide as an initiator, the reaction is carried out at 120°C for 9 hours, and the tetradecyl methacrylate-N-vinylimidazole pour point depressant is used.

[0048] The preparation method of the composite diesel pour point depressant is as follows: directly mixing ethanolamine, triethanolamine and myristyl methacrylate-N-vinylimidazole pour point depressant.

[0049] When the ...

Embodiment 3

[0051] A composite diesel pour point depressant containing polar nitrogen-containing compounds, comprising the following components and contents in parts by weight:

[0052] 30 parts of ethanolamine,

[0053] 10 parts of triethanolamine,

[0054] 60 parts of myristyl methacrylate-N-vinylimidazole pour point depressant.

[0055]Wherein, the preparation method of myristyl methacrylate-N-vinylimidazole pour point depressant is: after myristyl methacrylate and N-vinylimidazole are mixed in a mol ratio of 3:1, join in toluene solvent, Under the condition that 0.9% of the total mass of reactants is benzoyl peroxide as an initiator, the reaction is carried out at 120°C for 9 hours, and the tetradecyl methacrylate-N-vinylimidazole pour point depressant is used.

[0056] The preparation method of the composite diesel pour point depressant is as follows: directly mixing ethanolamine, triethanolamine and myristyl methacrylate-N-vinylimidazole pour point depressant.

[0057] When the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com