Patents

Literature

36 results about "N-vinylimidazole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Vinylimidazole polymerizes radically in an aqueous or alcoholic solution to form homopolymers with average molar masses of from 2,000 to 50,000, which, ... such as mercaptoethanol, the undesired residual content of the N-vinylimidazole can be reduced to less than 50 ppm, although the molar mass of the polymer obtained also decreases.

Electroplating solution for acid copper-plating for printed circuit board as well as preparation method and application method for same

The invention discloses an electroplating solution for acid copper-plating for a circuit board as well as a preparation method and an application method for the same. The electroplating solution disclosed by the invention is characterized in that a home-made synthesised levelling agent is added, and the levelling agent is matched with water-soluble copper salt, sulphuric acid, a brightening agent, chloride ions, a gloss agent and a surfactant to form the electroplating solution. The home-made levelling agent is one or more of the copolymer of N-vinyl imidazole onium salt and propenyl esters, and the polymer of N-vinyl imidazole and epoxides. The electroplating solution containing the home-made synthesised levelling agent is great in covering power and the dispersing power, capable of improving the uniform distribution of copper layers in the through holes of the printed circuit board, and capable of effectively reducing the ratio of the thickness of the surface copper layers to the thickness of the copper layers in the centres of the holes.

Owner:CENT SOUTH UNIV

Cosmetic and/or dermatological use of a composition containing at least one oxidation-sensitive hydrophilic active principle and at least one N-vinylimidazole polymer or copolymer

InactiveUS20030124161A1Good cosmetic effectIncrease differentiationCosmetic preparationsBiocideWater activityAcoric acid

The invention relates to the use of a composition containing, preferably in a physiologically acceptable medium comprising an aqueous phase, at least one oxidation-sensitive hydrophilic active principle selected from the group consisting of ascorbic acid and its derivatives and at least one non-crosslinked N-vinylimidazole polymer or copolymer, the active principle and the polymer or copolymer both being present in the aqueous phase, for promoting the synthesis of epidermal ceramides and / or for improving the barrier function of the skin, among other uses.

Owner:LOREAL SA

Method for inhibiting or controlling inorganic scale formations with copolymers of acrylamide and quaternary ammonium salts

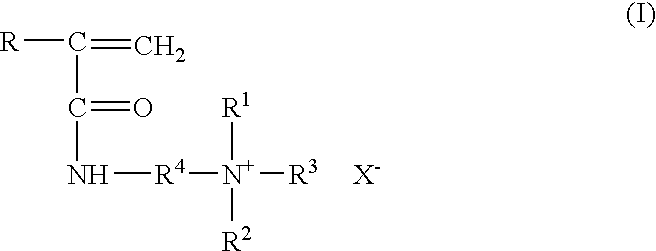

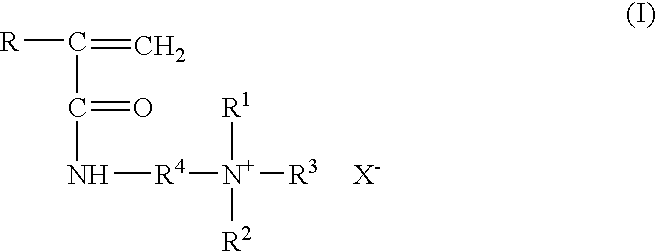

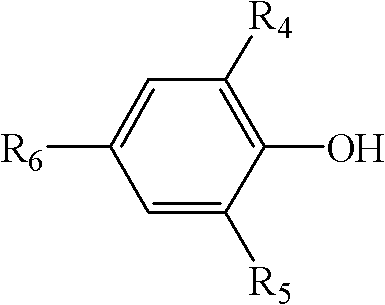

InactiveUS7398824B1Improve efficiencyImprove thermal stabilityCleaning apparatusFluid removalZinc bromideMethyl group

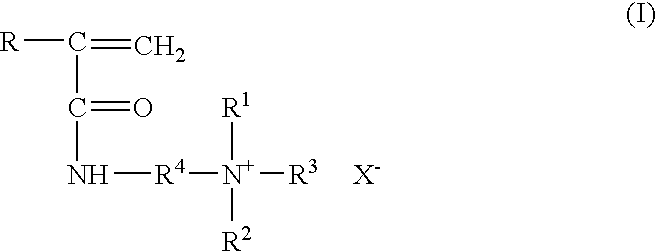

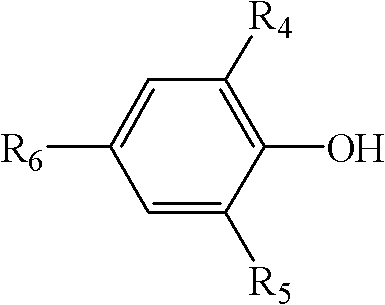

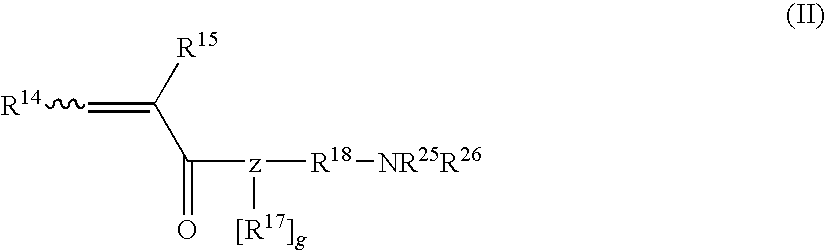

A formulation containing a copolymer derived from a cationic monomer effectively inhibits and controls the formation of inorganic scales. Suitable copolymers include those comprising an acrylamide unit and a quaternary ammonium salt group, and optionally an acrylate and / or nitrogen heterocyclic monomer including those wherein the quaternary ammonium salt is a unit of the formula:wherein R is methyl or hydrogen; R4 is a C1 to C6 alkyl group, optionally substituted with halogen, hydroxyl and alkoxy groups, X is halogen; and R1, R2 and R3 are independently selected from the group consisting of alkyl and alkoxy groups. Suitable nitrogen heterocyclic compounds include N-vinylpyrrolidone, N-vinylformamide, N-vinylacetamide, N-vinylcaprolactam, N-vinylimidazole and N-vinylpyridine. The copolymers have particular applicability in the control and inhibition of zinc sulfide or iron sulfide scales, typically formed when zinc bromide brines are used as fluids in the treatment of a gas or oil well, such as a completion fluid.

Owner:BAKER HUGHES INC

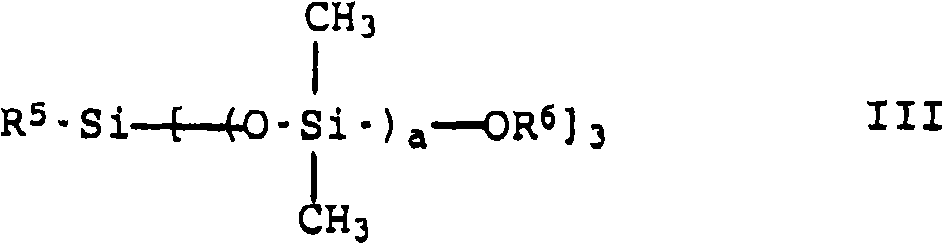

Polar grafted polyolefins, methods for their manufacture, and lubricating oil compositions containing them

InactiveUS20020042349A1Excellent Low Temperature ViscosityLess expensiveAdditivesPolyolefinPolymer science

A grafted polyolefin containing one or more of N-vinylimidazole, 4-vinylpyridine, or other ethylenically-unsaturated nitrogen-containing or oxygen-containing graftable monomers grafted to a polyolefin copolymer is disclosed. The grafted polyolefin preferably has a weight average molecular weight of from about 20,000 to about 500,000, a polydispersity of less than about 10, and an ADT value of at least about 8. The grafted polyolefin can be defined as containing more than about 1.2% by weight of grafted monomer on a polyolefin, or as containing at least about 13 moles of graftable monomers per mole of polyolefin, or as having an asphaltene dispersancy test (ADT) value of at least about 8. Also described is a lubricating oil comprising a lubricant base oil and a grafted polyolefin as described above. Also described is a method of making a dispersant viscosity index improver. N-vinyl-imidazole or other ethylenically unsaturated nitrogen-containing and / or oxygen-containing graftable monomers and a graftable polyolefin are reacted with enough of an initiator to graft the monomer to the polyolefin. The initiator and / or graftable monomer is added to the other ingredients, maintained at the reaction temperature, over a period of time. The reaction temperature is maintained at a level high enough to give acceptable reaction times. The N-vinylimidazole and the initiator each can be added at a uniform, relatively slow rate during the reaction.

Owner:CASTROL LTD

Functional polymer and preparation method and application thereof

InactiveCN101885797ALarge specific surface areaThe synthetic route is simpleComponent separationMaterial weighingPolymer scienceHeteroatom

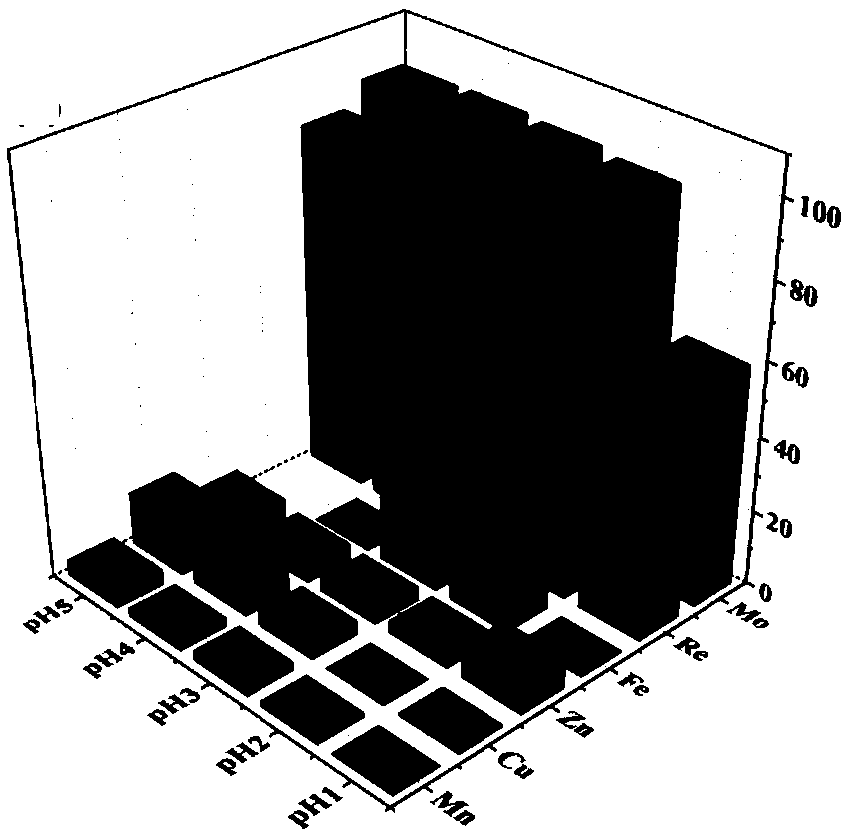

The invention discloses a functional polymer. The functional polymer is a random copolymer consisting of N-vinylimidazole structural unit and 2-mercaptobenzothiazole derivative structural unit, and the weight-average molecular weight of the random copolymer is 6,000 to 15,000; and the molar percentage content of the N-vinylimidazole structural unit in the random copolymer is 20 to 45 percent, and the molar percentage content of the 2-mercaptobenzothiazole derivative structural unit is 55 to 80 percent. The invention also discloses a preparation method for the functional polymer and application. The polymer structure contains bonding points of an imidazole ring and S and N heteroatom groups easily coordinated with heavy metal ions, so the polymer prepared by the method and a film thereof can selectively adsorb and detect the heavy metal ions in the water.

Owner:ZHEJIANG UNIV

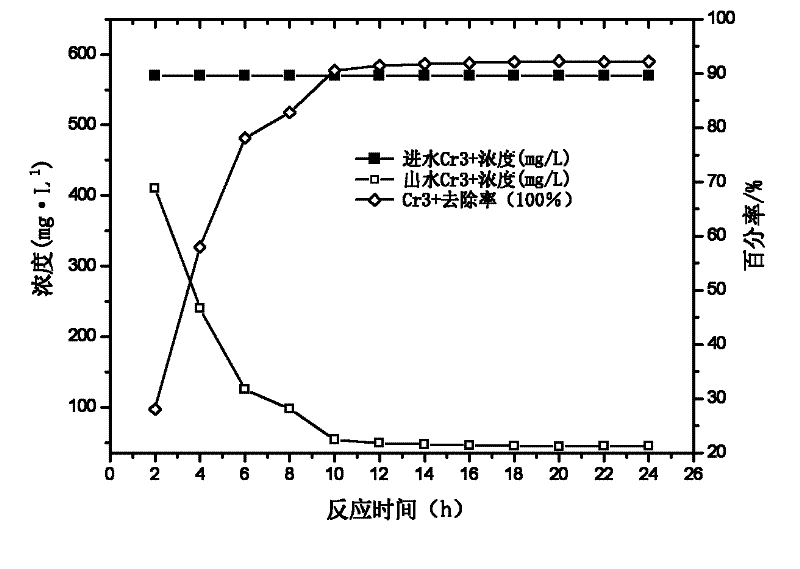

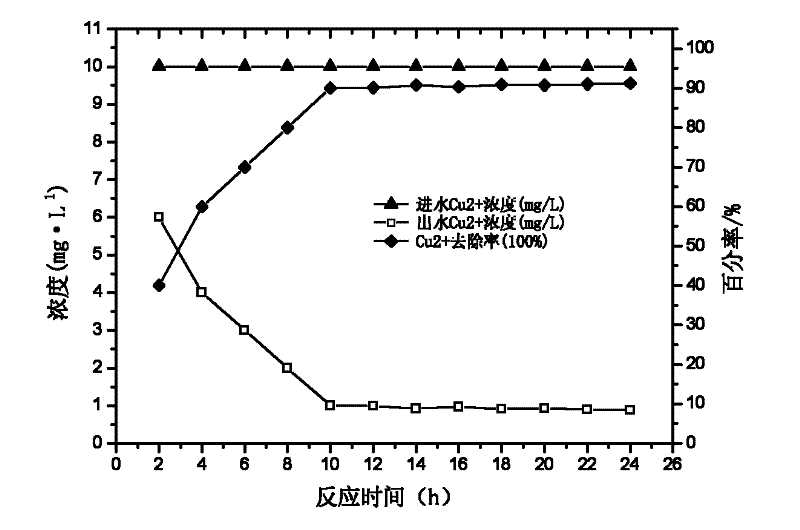

Polymer hydrogel, preparation method and application thereof to water treatment

InactiveCN102199245AGuaranteed pureImprove pore structureOther chemical processesWater contaminantsPolymer scienceHigh energy

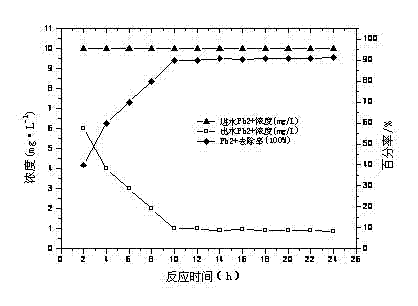

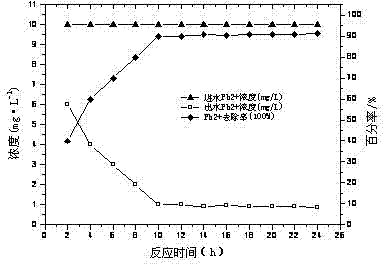

The invention relates to polymer hydrogel and a preparation method thereof. The polymer hydrogel comprises polymerized N-vinyl imidazole and hydroxyethyl acrylate, wherein the molar ratio of the N-vinyl imidazole to the hydroxyethyl acrylate is 1:1 to 1:9. The preparation method comprises the following steps of: uniformly mixing the N-vinyl imidazole, the hydroxyethyl acrylate and water; then charging nitrogen, and polymerizing by adopting high-energy ray irradiation at the temperature of minus 63 DEG C to minus 95 DEG C to obtain the polymer hydrogel. The polymer hydrogel provided by the invention has a good pore structure, contains multiple functional groups capable of adsorbing heavy metals, has high capacity of adsorbing ions including Pb<2+>, Cr<3+>, Cd<2+> and Cu<2+>, can effectively adsorb and chelate heavy metal ions, has certain mechanical strength and long service life, and can be used for sewage treatment. In the preparation method, an initator does not need to be added so that the pureness of the polymer is ensured; and the preparation method is simple and easy to operate.

Owner:NANJING UNIV

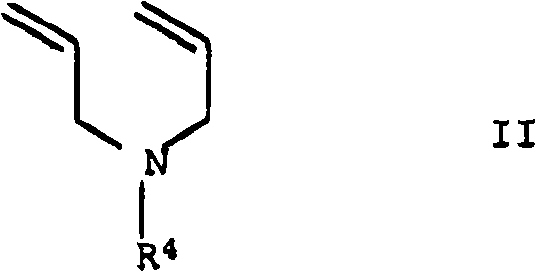

Use of polymers based on n-vinyl caprolactam in hair cosmetics

Use of polymers of 30-65% by weight of N-vinylcaprolactam, 35-65% by weight of a monomer mixture of N-vinylimidazole and vinylpyrrolidone, where the weight ratio of N-vinylimidazole to vinylpyrrolidone is between 0.085 and 0.30, 0-15% by weight of a nitrogen-containing quaternizable monomer (A), which is different from N-vinylimidazole, where the sum of monomer (A) and N-vinylimidazole is less than 18% by weight, in cosmetic preparations.

Owner:BASF AG

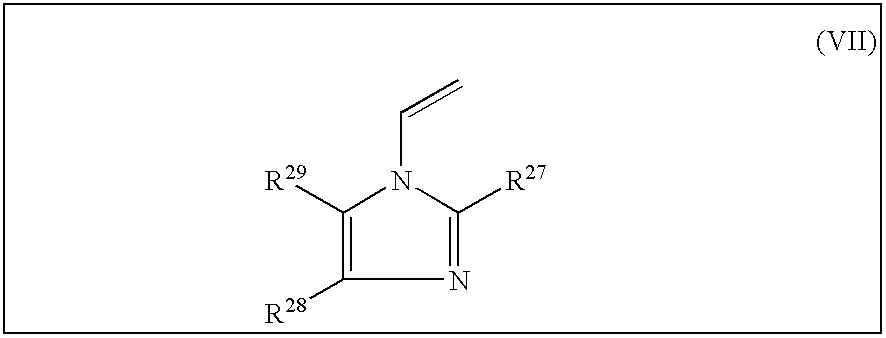

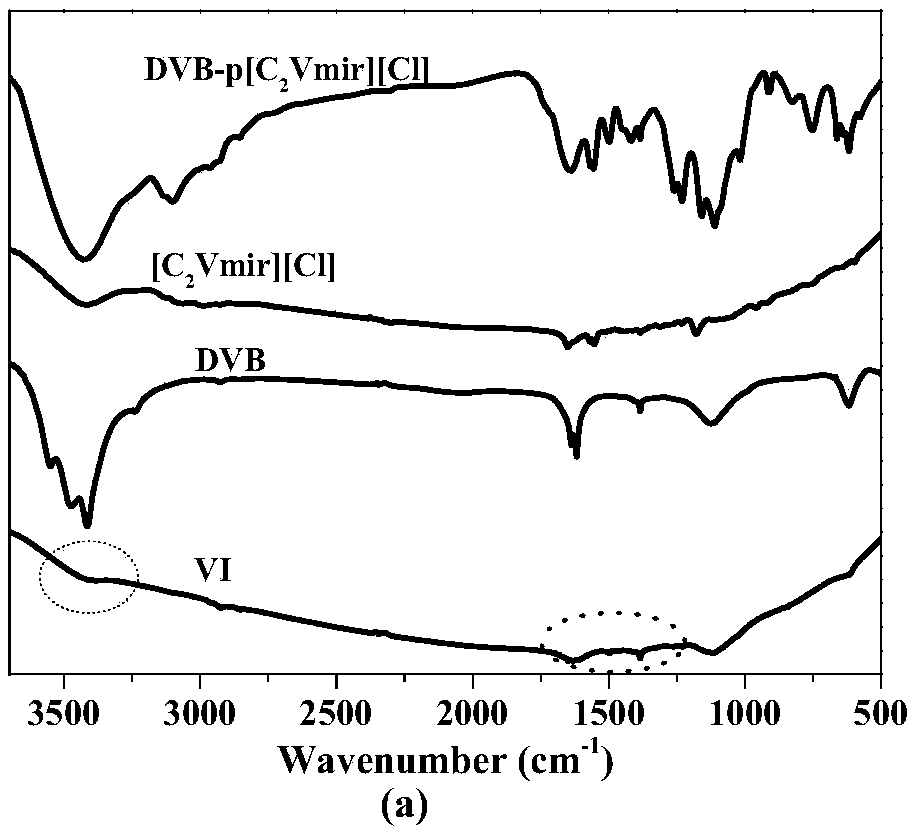

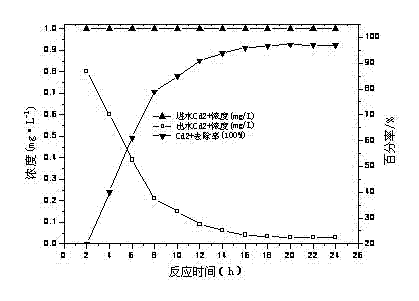

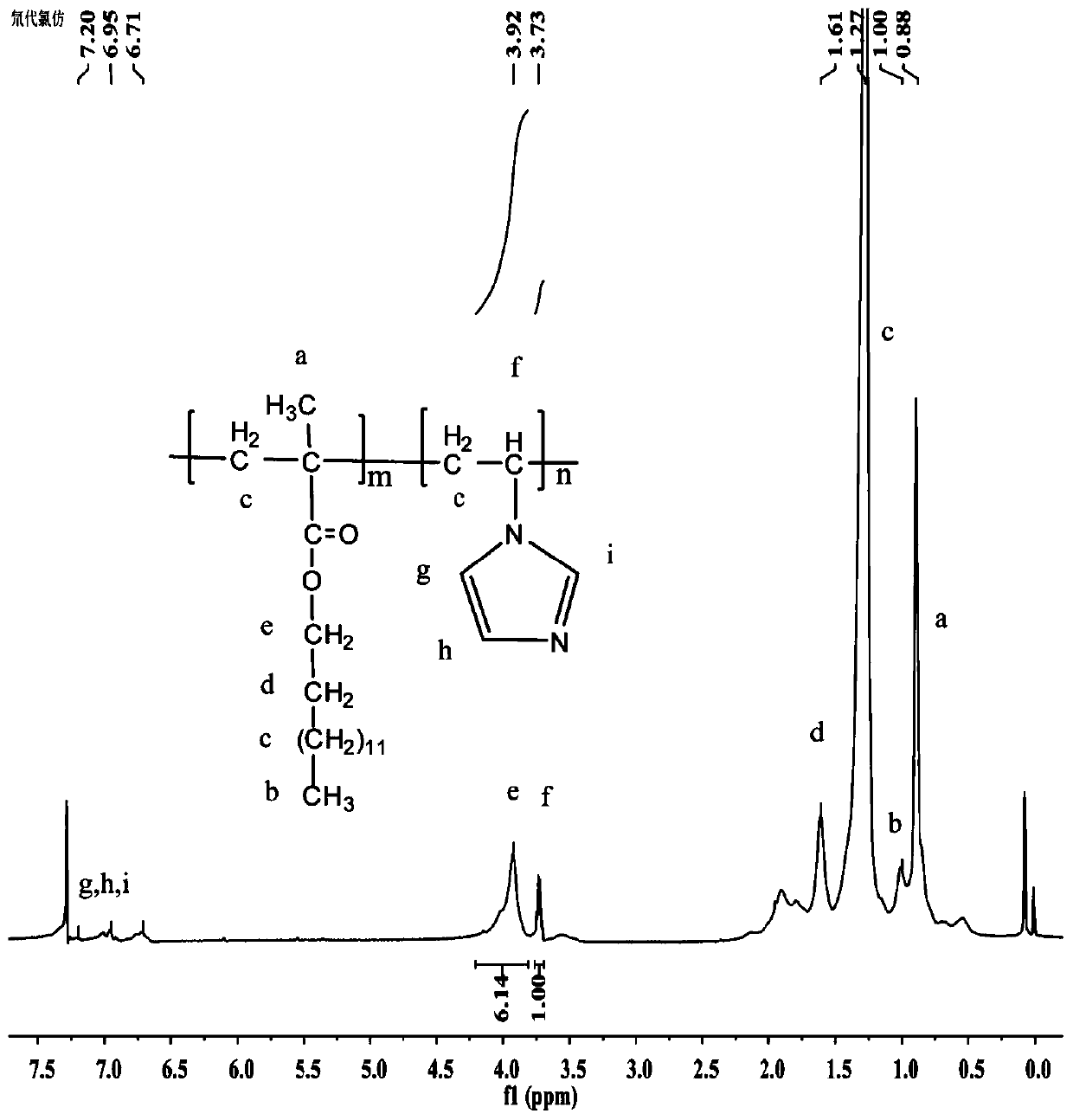

Polyimidazole ionic liquid based copolymer, and preparation method and application thereof

ActiveCN108912269AImprove separation efficiencyLarge adsorption capacityOther chemical processesWater contaminantsRheniumPotassium persulfate

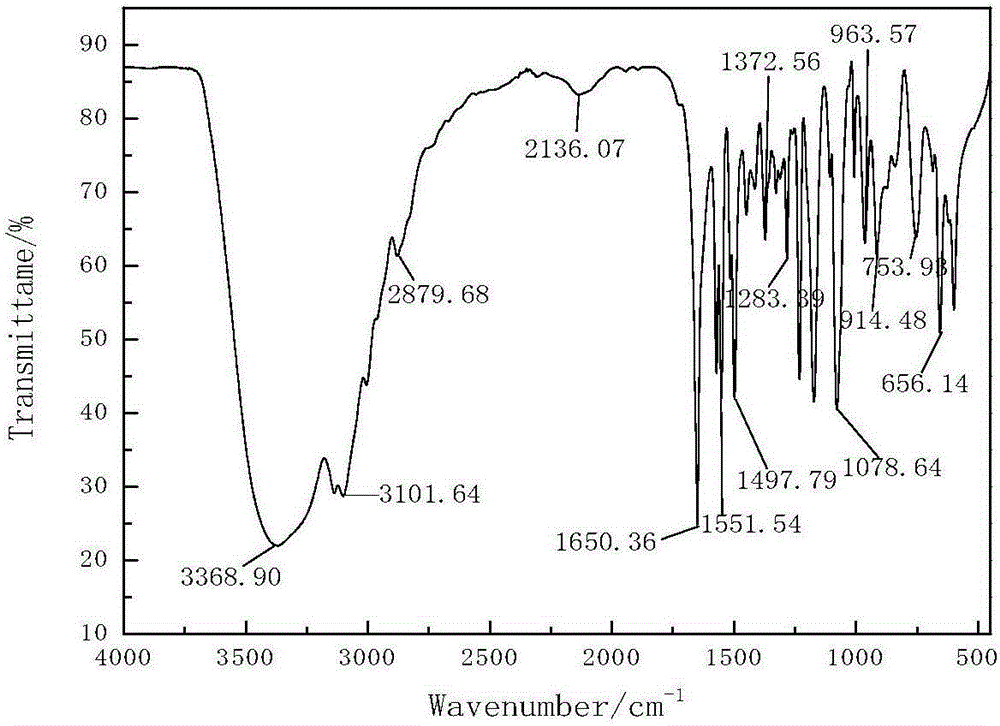

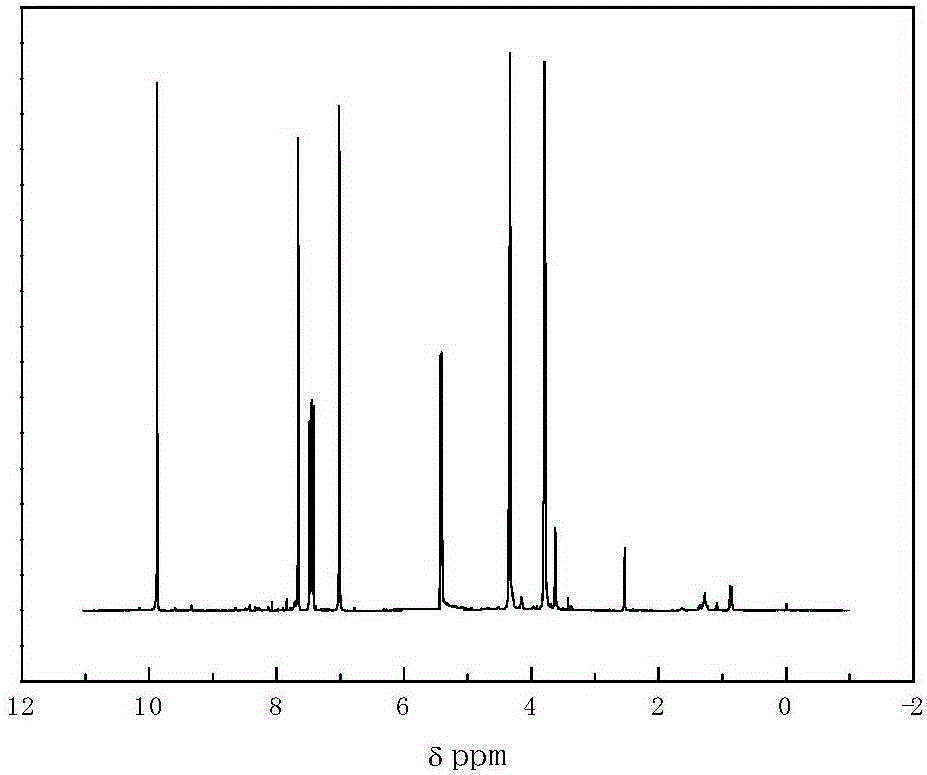

The invention relates to a polyimidazole ionic liquid based copolymer, and a preparation method and an application thereof, belonging to the field of adsorbent synthesis. The preparation method comprises the following steps: weighing N-vinylimidazole and dichloroalkane, then adding the N-vinylimidazole and the dichloroalkane into a reactor, adding acetonitrile, carrying out uniform mixing, carrying out a reaction at 70 to 80 DEG C for 8 to 12 h, carrying out reduced pressure distillation to remove the acetonitrile, and carrying out washing and purifying so as to obtain an imidazole ionic liquid with a formula of [CxVmir][Cl]; and subjecting the imidazole ionic liquid with the formula of [CxVmir][Cl], N,N-methylene bisacrylamide MBA, divinyl benzene DVB and the acetonitrile to ultrasonic and uniform stirring, adding potassium persulfate, carrying out a reaction at 70 to 80 DEG C for 18 to 24 hours, and carrying out cooling, vacuum filtering, washing, purifying and vacuum drying so as toobtain a target product namely the polyimidazole ionic liquid based copolymer with a formula of DVB-p[CxVmir][Cl]. The preparation method provided by the invention is simple and safe, has high adsorption efficiency to rhenium, is energy-saving and environmentally-friendly, and has large adsorbing capacity and application practicality.

Owner:LIAONING UNIVERSITY

Magnetic supported catalyst and application thereof in preparing polyphenyleneoxide in aqueous medium

InactiveCN102060990ALarge specific surface areaHigh catalytic efficiencyChemical recyclingWater solublePolyphenyl ether

The invention discloses a magnetic supported catalyst, which is a complex of a nano magnetic particle surface grafted polyvinyl imidazol ligand and metal ions. A molar ratio of imidazol groups to the metal ions in the complex is (0.5-300):1; and the polyvinyl imidazol ligand is homopolymer of N-polyvinyl imidazol monomers or copolymer of N-polyvinyl imidazol monomers and one or more types of water-soluble monomers. The catalyst has high catalytic efficiency, and can be separated from a reaction medium by applying a magnetic field, so that the catalyst is recycled, and solves the problem that the conventional catalyst has low catalytic efficiency of preparing polyphenyleneoxide (PPO) in a reaction medium, particularly in an aqueous medium, and is difficult to recycle. The invention also discloses a preparation method and application of the magnetic supported catalyst. The preparation method is easy to operate and control, and is suitable for industrial production.

Owner:ZHEJIANG UNIV

Composition containing at least one oxidation-sensitive hydrophilic active principle and at least one N-vinylimidazole polymer or copolymer useful to prevent and/or treat cutaneous signs of intrinsic ageing

InactiveUS20030125378A1Good cosmetic effectPowder deliveryCosmetic preparationsPolymer chemistryN-vinylimidazole

The invention relates to a composition containing, preferably in a physiologically acceptable medium comprising an aqueous phase, at least one oxidation-sensitive hydrophilic active principle selected from the group consisting of ascorbic acid and its derivatives and at least one non-crosslinked N-vinylimidazole polymer or copolymer, the active principle and the polymer or copolymer both being in the aqueous phase, useful for preventing and / or treating cutaneous signs of intrinsic ageing.

Owner:LOREAL SA

Use of cationic copolymers of amine-containing acrylates and N-vinylimidazolium salts in hair cosmetic preparations

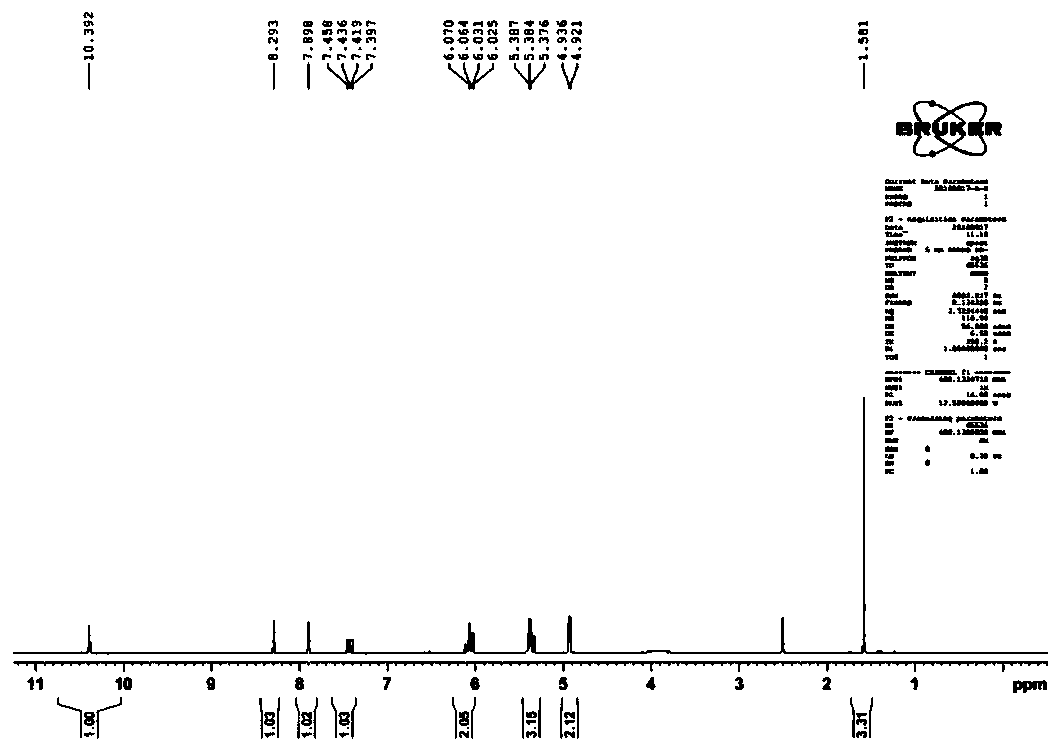

The present invention relates to the use of cationic polymers obtainable by free-radical copolymerization of a) 60 to 99 mol % of at least one 1-vinylimidazole monomer, b) 1 to 40 mol % of at least one free-radically polymerizable quaternizable monomer b1) or methacrylic acid b2) and c) 0 to 30 mol % of at least one further free-radically copolymerizable monomer different from a) and b) in hair cosmetic preparations.

Owner:BASF SE

Use of a composition containing at least one oxidation-sensitive hydrophilic active principle and at least one N-vinylimidazole polymer or copolymer

InactiveUS20030124075A1Good cosmetic effectMaintain good propertiesCosmetic preparationsHair cosmeticsWater activityAdditive ingredient

The invention relates to the use of a composition contains at least one oxidation-sensitive hydrophilic active principle selected from the group consisting of ascorbic acid and its derivatives and at least one non-crosslinked N-vinylimidazole polymer or copolymer, the active principle and the said polymer or copolymer both being in the aqueous phase, for lightening and / or depigmenting the skin and / or hair, including body hair.

Owner:LOREAL SA

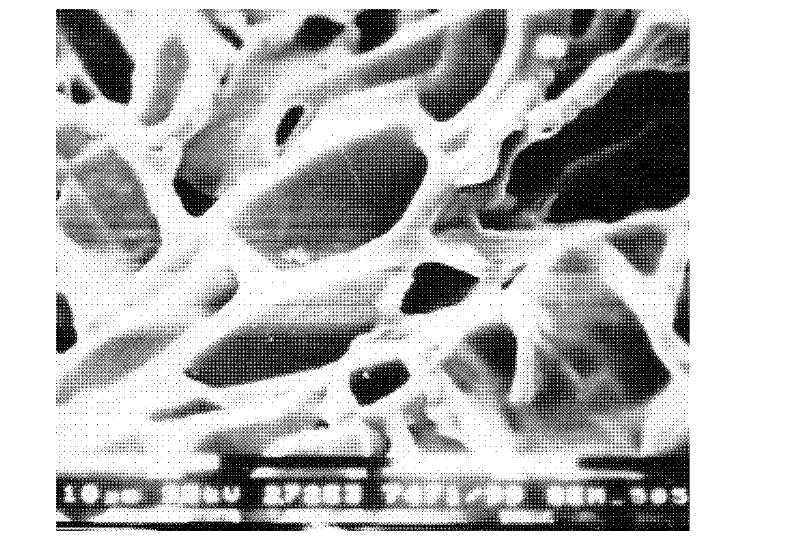

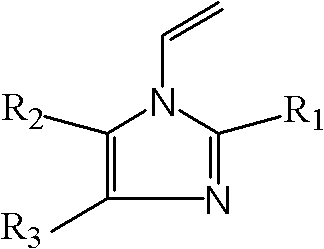

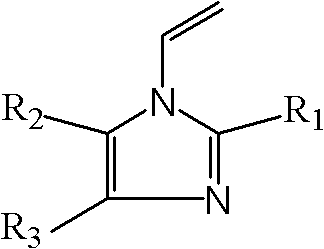

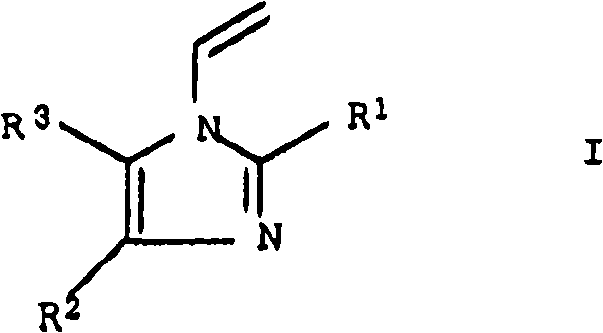

Method for preparing heat insulating polyurethane automotive trim leather

ActiveCN105040461AGood heat insulationImprove comfortTextiles and paperPolyurethane dispersionSurface layer

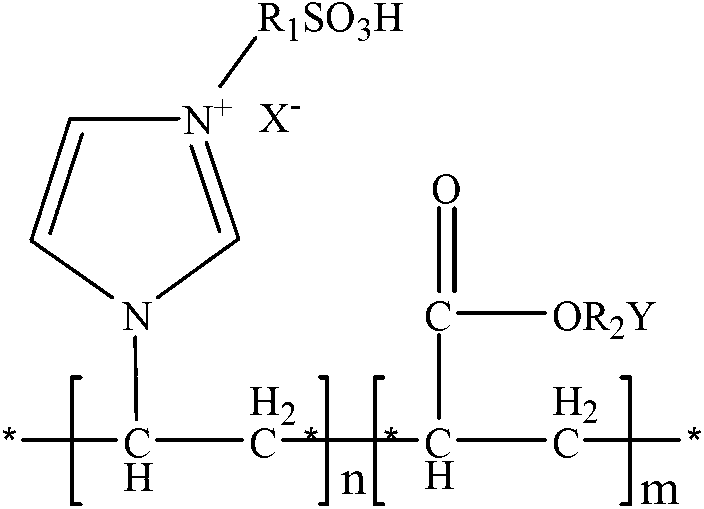

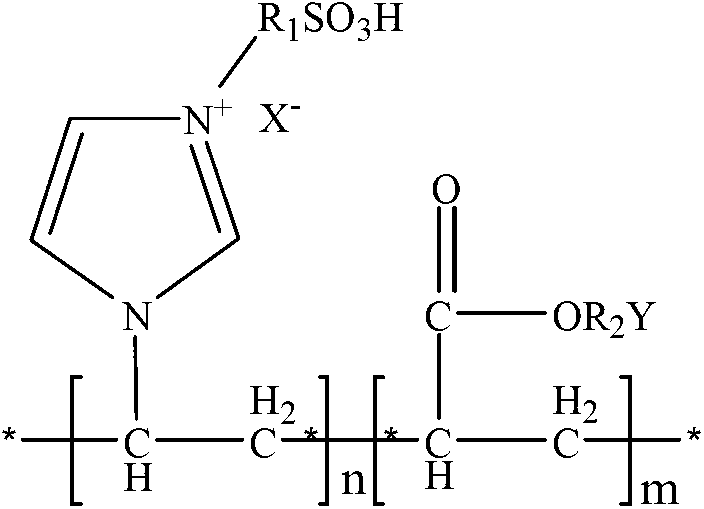

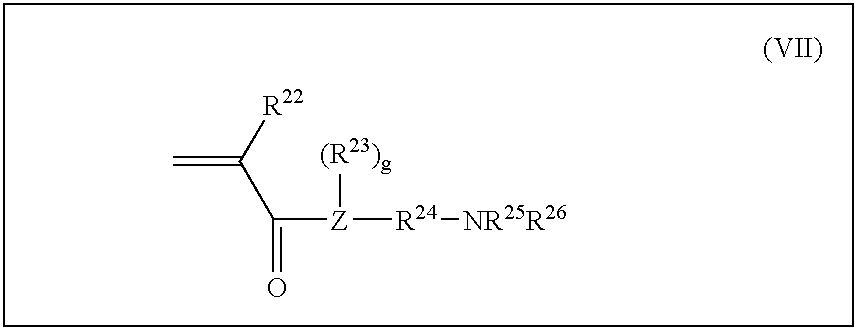

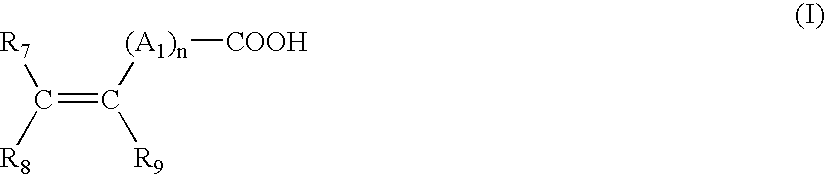

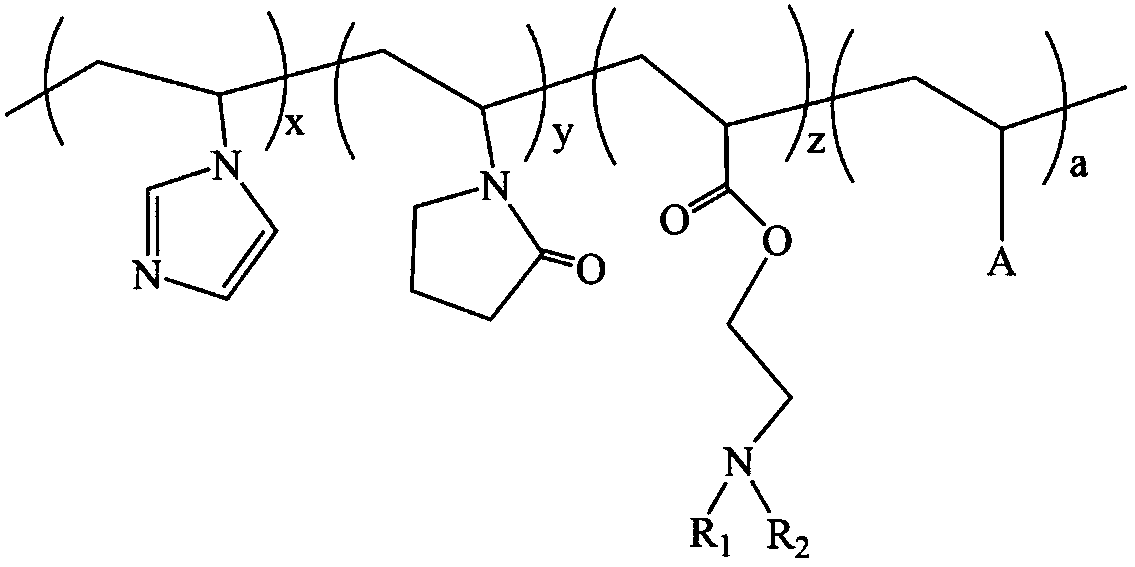

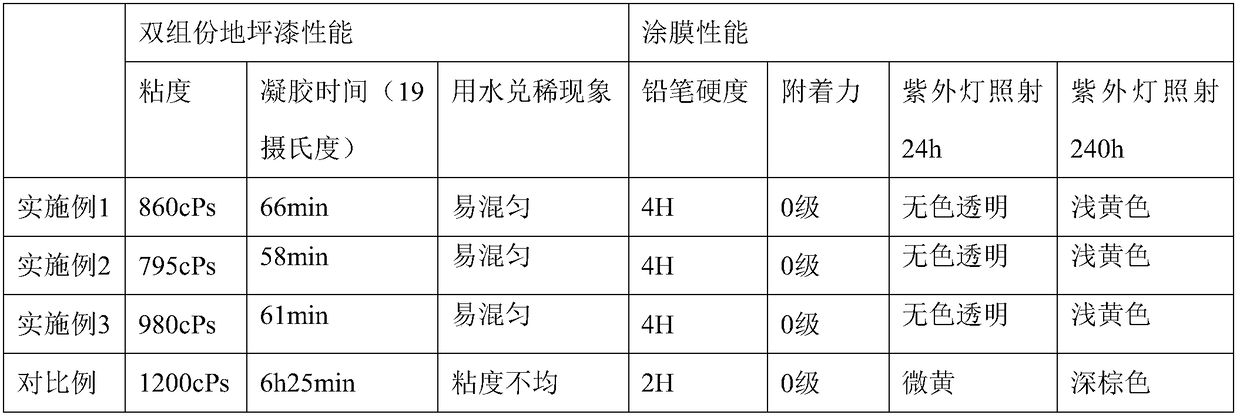

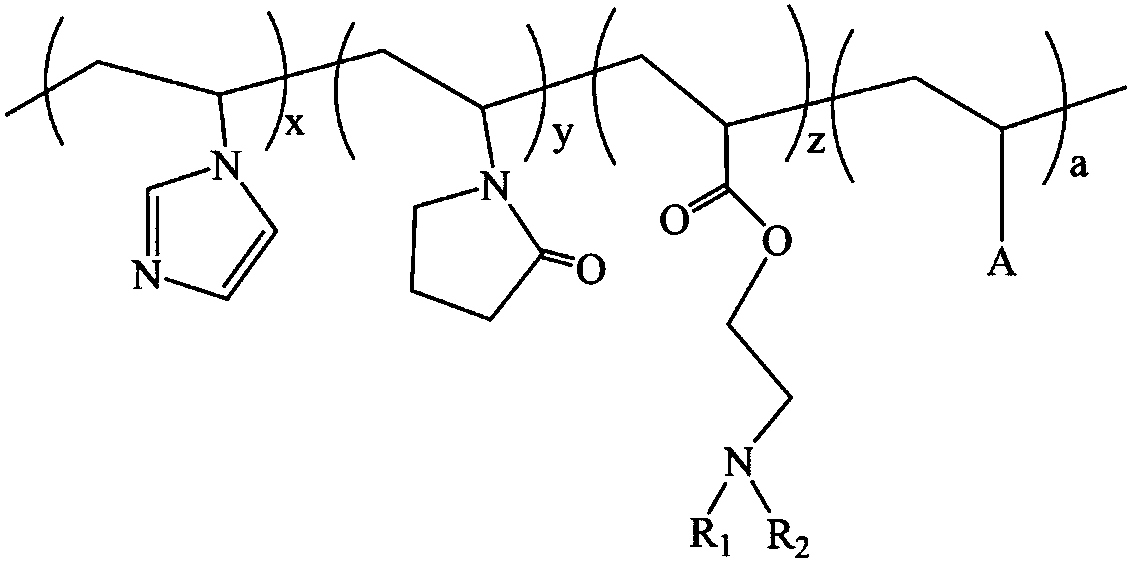

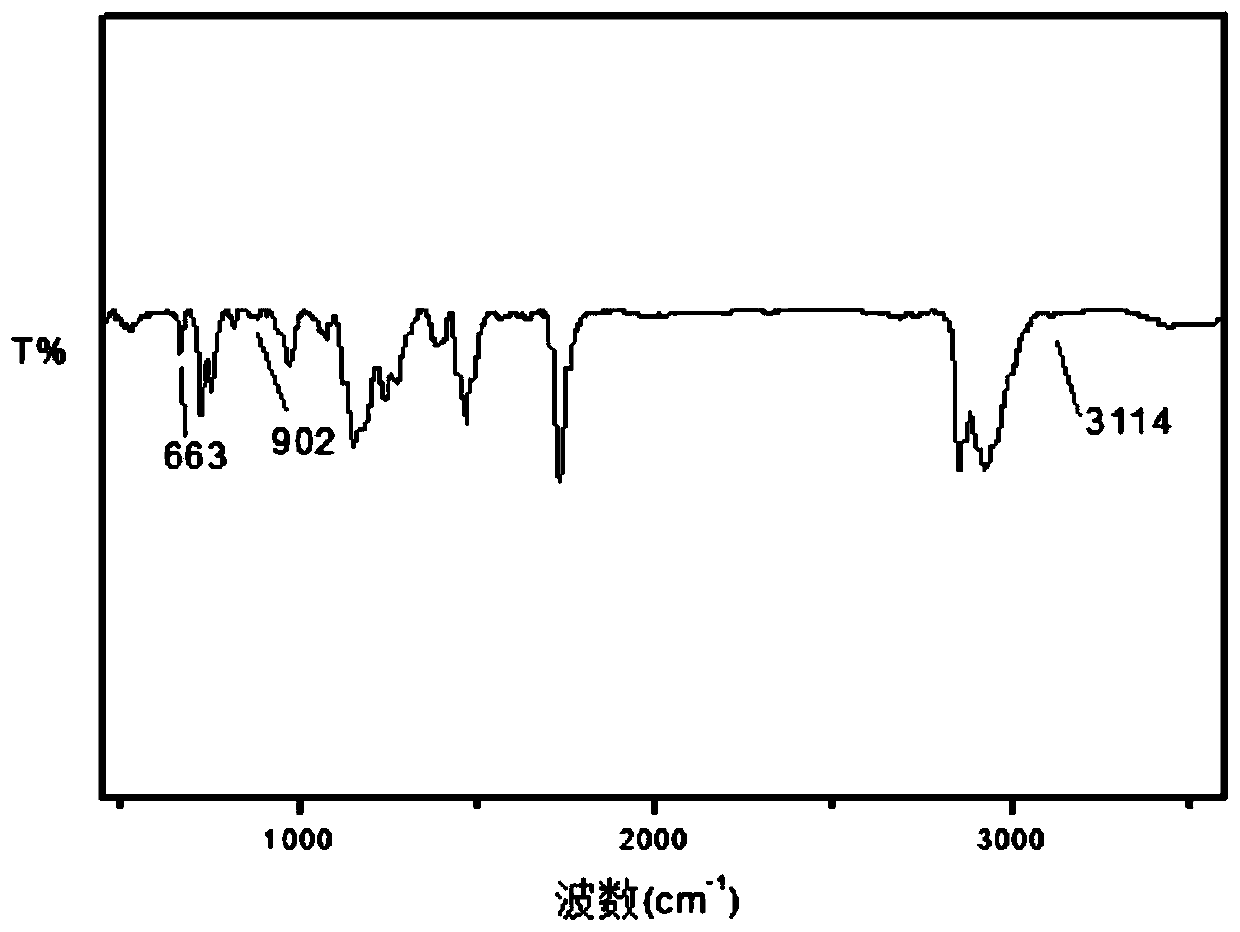

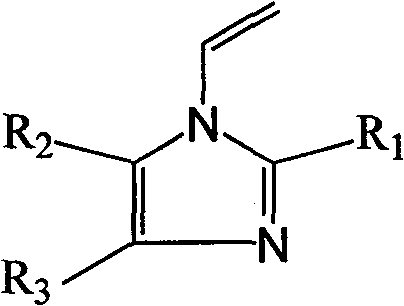

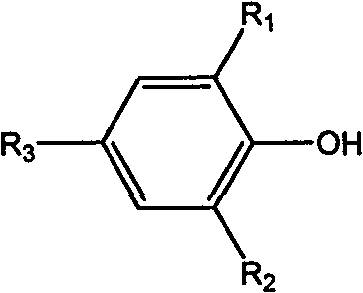

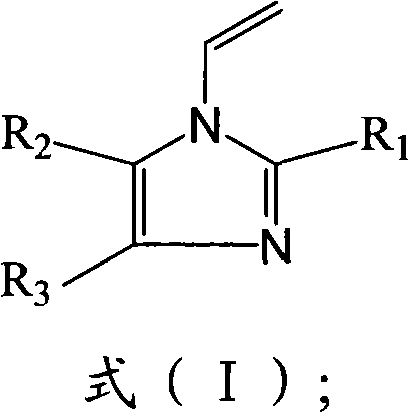

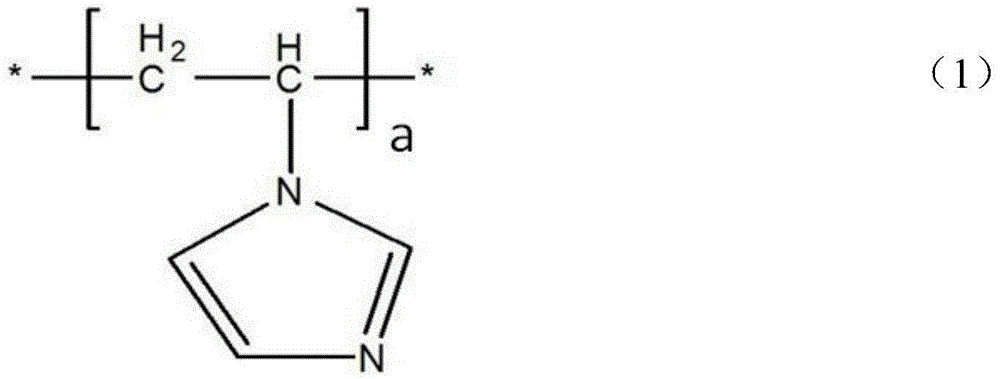

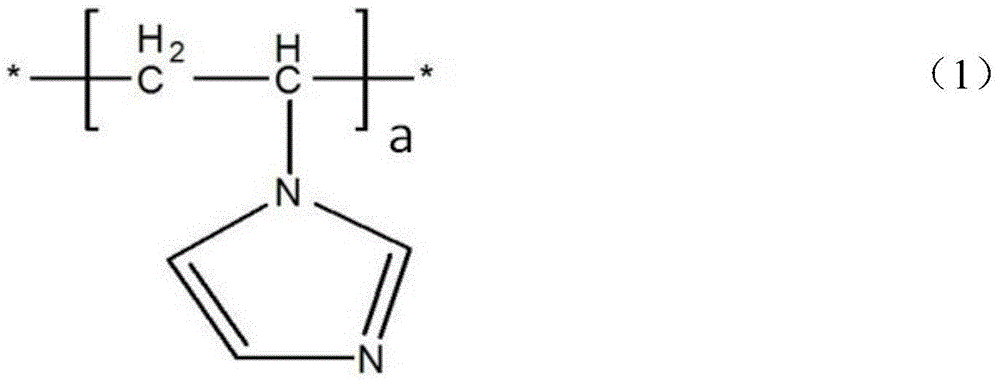

The invention relates to a method for preparing heat insulating polyurethane automotive trim leather. The method includes the following steps that a, the surface of release paper is coated with waterborne polyurethane dispersion, the release paper is placed at the temperature of 110-120 DEG C, and a surface layer is obtained after drying; b, the surface of the surface layer is coated with polyurethane and an expanding agent through mechanical foaming, then the surface layer is placed at the temperature of 110-120 DEG C to be dried for 20-40 min, and a porous foaming layer is formed; c, base cloth is attached to the foaming layer, the foaming layer is placed at the temperature of 100-120 DEG C to be cured for 10-15 hours, then, separation and winding are conducted, and the heat insulating polyurethane automotive trim leather is obtained. The waterborne polyurethane dispersion comprises, by mass, 75-80% of polyurethane resin, 10-15% of N-vinyl imidazole onium salt polymers, 3-5% of swelling powder, 1-2% of defoaming agent, 1-2% of flatting agent, 1-5% of nano graphene and 1-3% of feeling agent. The number-average molecular weight of the polyurethane resin is 1,000-5,000. The molecular structure general formula of the N-vinyl imidazole onium salt polymers is shown in the specification, and the number-average molecular weight of the N-vinyl imidazole onium salt polymers is 1,000-5,000. A vacuum environment can be formed, and no molecule exists in the vacuum environment so that heat cannot be conducted, and the good heat insulating effect is achieved.

Owner:江苏尚科聚合新材料有限公司

Aerosol device containing a hair composition

InactiveUS20080035166A1Strengthen the relative fixedGood cosmetic effectCosmetic preparationsHair cosmeticsAqueous mediumHair treatment

The invention relates to an aerosol device containing a hair composition for hair styling which comprises, in a cosmetically acceptable aqueous medium, at least one copolymer based on N-vinylpyrrolidone and N-vinylimidazole units having a molecular weight greater than 100 KDaltons, and dimethyl ether as propelling agent. The invention also relates to the use of this device and to a method of hair treatment.

Owner:BASF AG

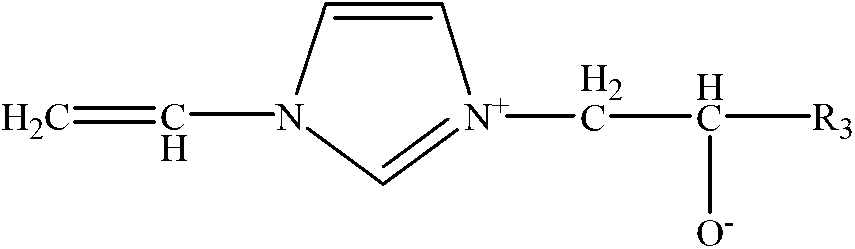

Ionic liquid and method for homogeneous phase-modified reed-reinforced PE (polyethylene) composite material thereof

The invention provides ionic liquid and a method for a homogeneous phase-modified reed-reinforced PE (polyethylene) composite material thereof, which belong to the field of synthesis and modification of materials. The ionic liquid is 1-vinyl-3-hydroxyethyl imidazole chlorine which is synthesized by N-vinyl imidazole and 2-chlorohydrin as raw materials according to the molar ratio of (1 to 1.5):1; the method adopts the ionic liquid, namely (1-vinyl-3-hydroxyethyl imidazole chlorine) to perform homogeneous phase modification on reeds, and the homogeneous phase-modified reed and PE are compounded, so that the homogeneous phase-modified reed-reinforced PE composite material is prepared. The ionic liquid designed by the invention can be used for effectively decreasing the surface polarity of the reeds, and increasing the dissolving capability of reed fibers. Compared with conventional methods, the method for performing homogeneous phase modification on the reeds by adopting the ionic liquid has the advantages of environment-friendly reaction solvents and recyclability; moreover, the homogeneous phase modification method improves the compatibility between the reeds and the PE, and the prepared homogeneous phase-modified reed-reinforced PE composite material has good mechanical property and excellent processability.

Owner:DALIAN POLYTECHNIC UNIVERSITY

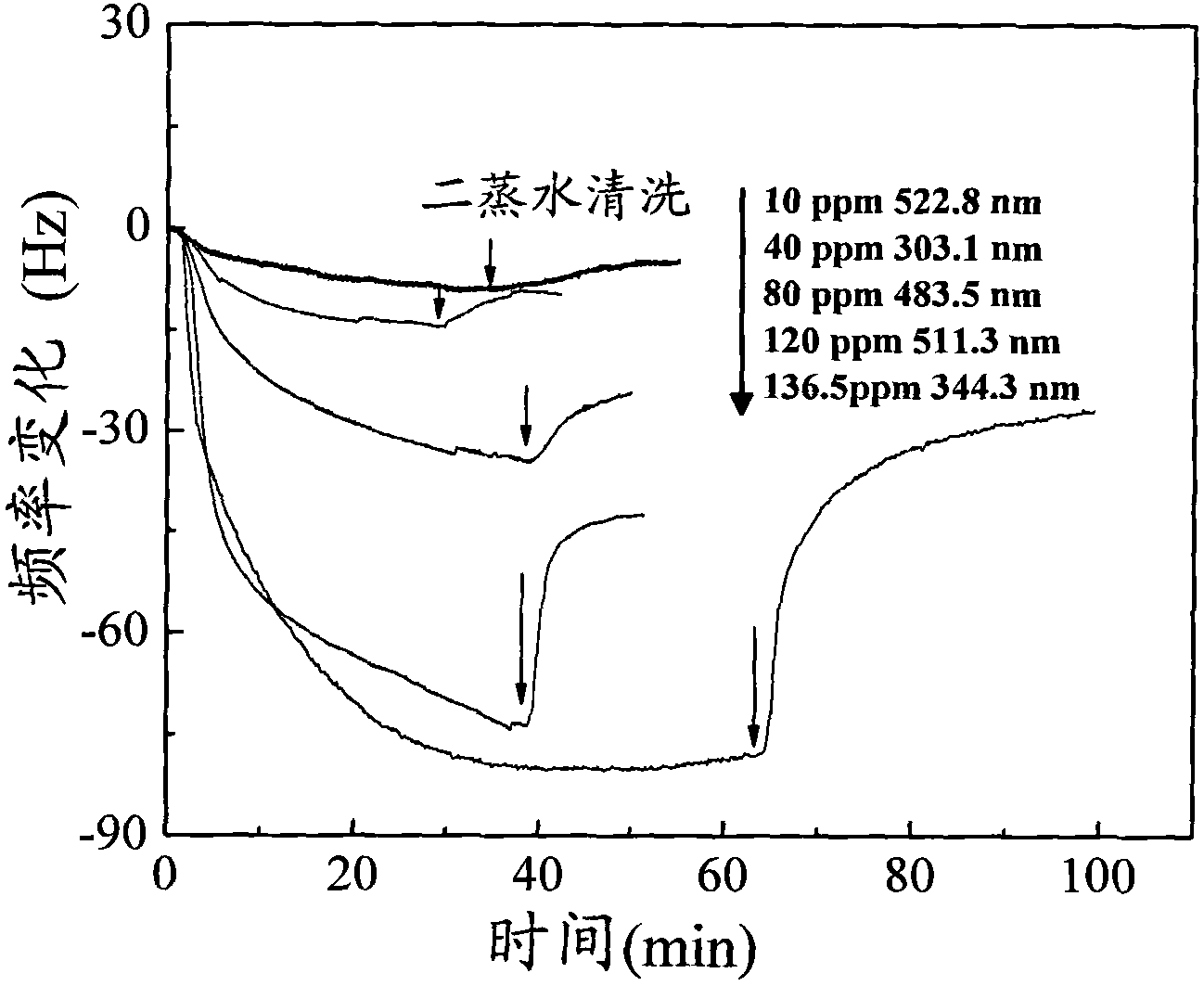

Radiation preparation method and application of polymer hydrogel-based nano iron oxide

InactiveCN102652915AImprove adsorption capacityEasy to operateOther chemical processesWater/sewage treatment by sorptionPolymer scienceHigh energy

The invention relates to a polymer hydrogel-based nano iron oxide which comprises polymer hydrogel formed by hydroxyethyl acrylate and N-vinyl imidazole in a polymerization form, and nano iron oxide is loaded on the polymer hydrogel, wherein the molar ratio between the hydroxyethyl acrylate and the N-vinyl imidazole is (1-9):1. A preparation method of the polymer hydrogel comprises the following steps of: (1) evenly mixing the hydroxyethyl acrylate, the N-vinyl imidazole and distilled water in a certain proportion, wherein the volume ratio of the mixture of the hydroxyethyl acrylate and the N-vinyl imidazole to the water is (1-2):5, and the molar ratio of the hydroxyethyl acrylate to the N-vinyl imidazole is (1-9):1; (2) after mixing, carrying out ultrasonic treatment for 7-13 minutes; (3) filling inert gas into the mixture obtained in the step (1) for guaranteeing an anaerobic state; and (4) adopting high-energy ray with the radiation dosage of 1*10<4>-1*10<8>Gy to irradiate the polymer hydrogel formed by polymerization within the temperature range of minus 63 DEG C to minus 95 DEG C.

Owner:NANJING UNIV

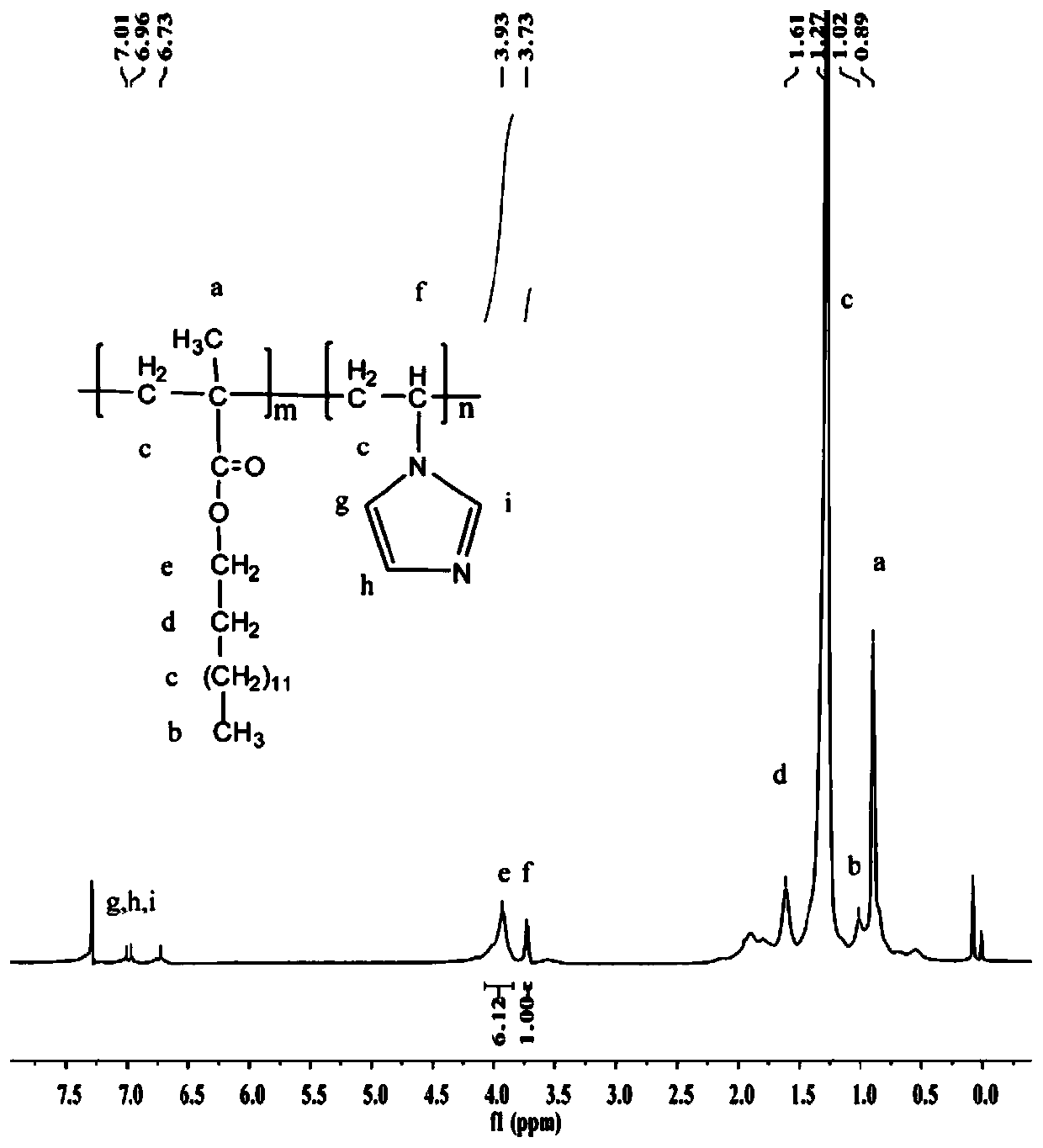

Reagent for reducing condensation point of diesel, and preparation method and application thereof

ActiveCN110093195AChanged crystallization behaviorChange crystal shapeLiquid carbonaceous fuelsFuel additivesSynthesis methodsCold filter plugging point

The invention provides a reagent for reducing the condensation point of diesel, and a preparation method and an application thereof. The reagent for reducing the condensation point of diesel comprisesa tetradecyl methacrylate-N-vinylpyrrolidone copolymer, or comprises the tetradecyl methacrylate-N-vinylpyrrolidone copolymer and a tetradecyl methacrylat-N-vinylimidazole copolymer. The above polymer diesel pour point depressant can further improve the low-temperature fluidity of the diesel, and has the advantages of simple synthesis method, small dosage, and small use amount of raw materials. The condensation point of diesel containing the reagent is 24-26 DEG C less than that of diesel free from the pour point depressant, and the cold filter plugging point of the diesel containing the reagent is 9-11 DEG C less than that of the diesel free from the pour point depressant, so that the diesel has a good fluidity at a low temperature.

Owner:SHANGHAI INST OF TECH

Method for preparing N-vinyl imidazole

InactiveCN102382059AReduce pollutionReduce manufacturing costOrganic chemistryDistillationEthane Dichloride

The invention relates to a method for preparing N-vinyl imidazole, comprising the steps of: carrying out substitution reaction on imidazole and first alkali metal hydroxide at a temperature of 50-90 DEG C in deionized water under the existence of an acid binding agent so as to generate imidazole alkali metal salt; adding the generated alkali metal salt into solution of dichloroethane and alcohol; carrying out the substitution reaction at a temperature of 60-100 DEG C so as to generate chloroethane imidazole; finally adding second alkali metal hydroxide into the chloroethane imidazole and carrying out elimination reaction at a temperature of 65-95 DEG C; after the reaction is finished, filtering and removing the alkali metal salt; reducing pressure and distilling out water, unreacted dichloroethane and alcohol at a temperature of 80-90 DEG C; and continuing raising the temperature to 100-110 DEG C and carrying out reduced pressure distillation so as to obtain the N-vinyl imidazole. The method provided by the invention has the advantages of little environmental pollution, low production cost, good product quality and high yield.

Owner:YANCHENG KANGLEYU NEW MATERIAL TECH

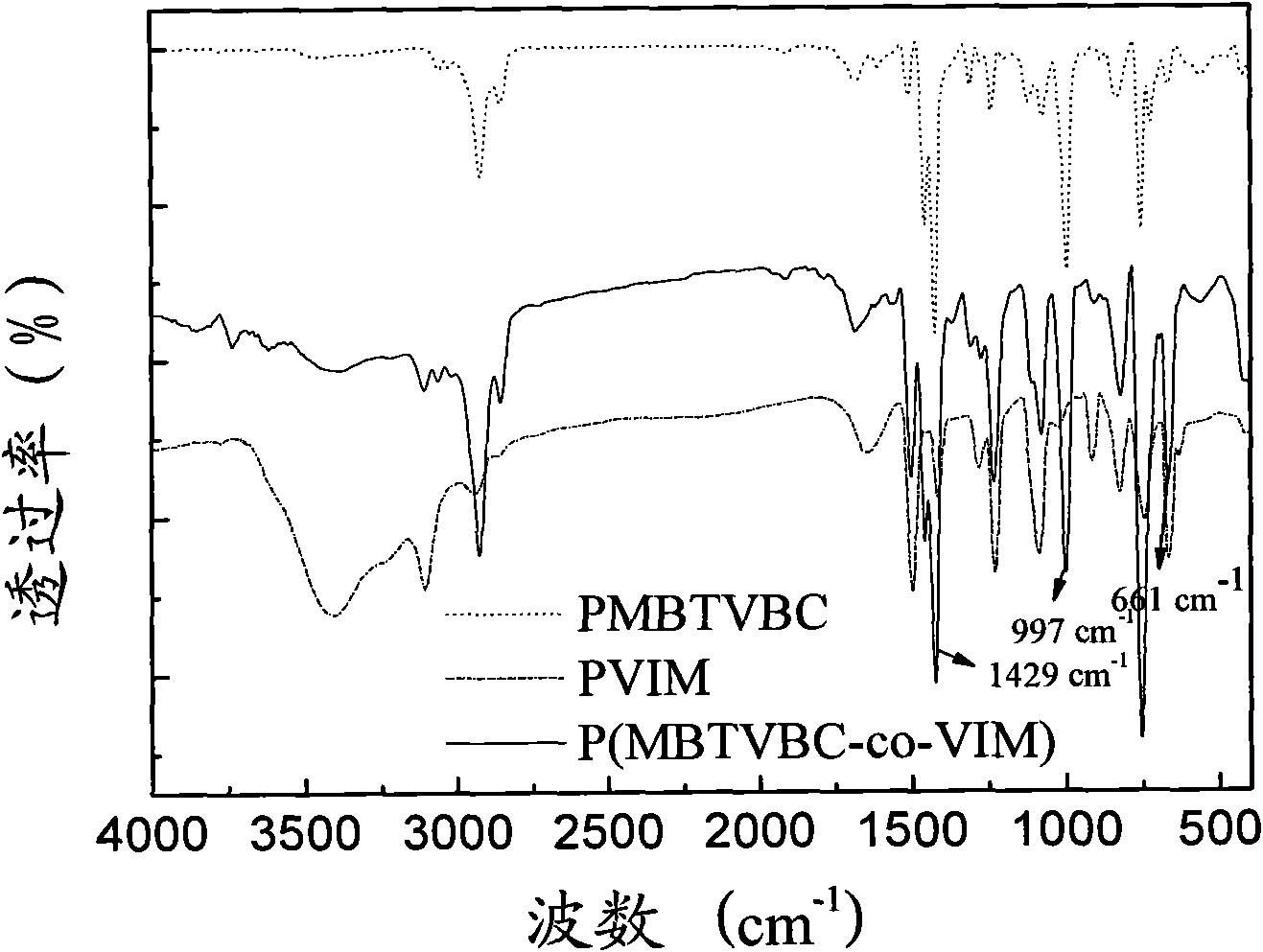

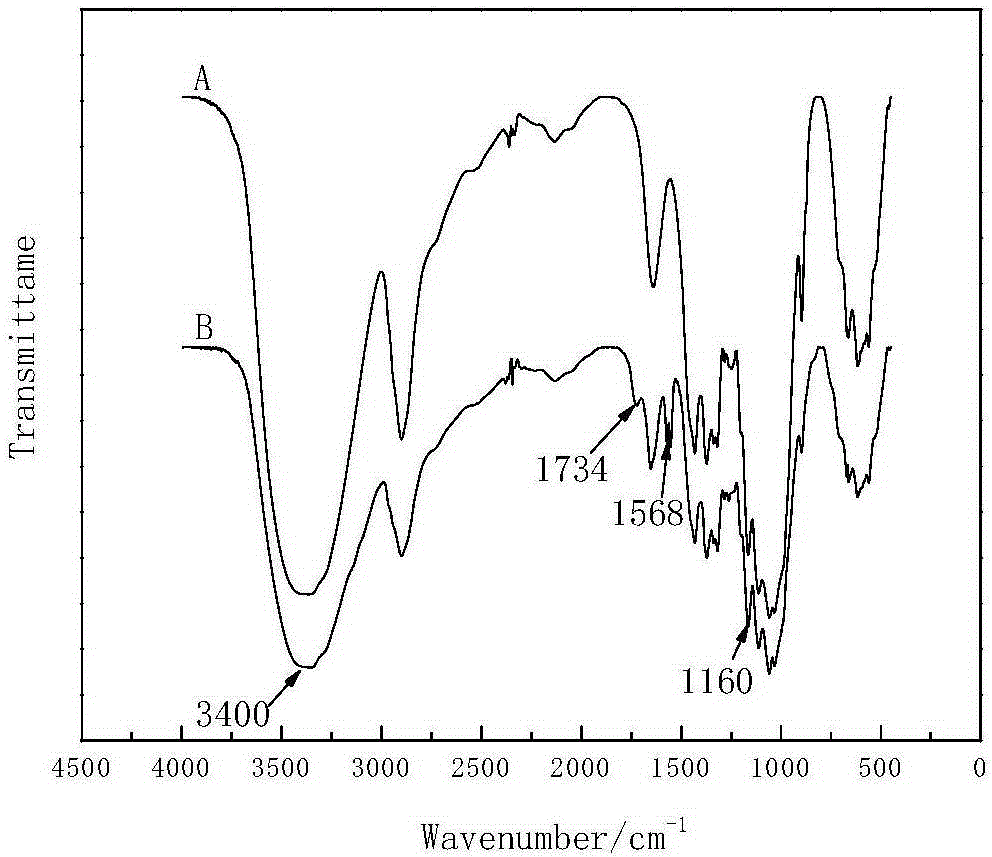

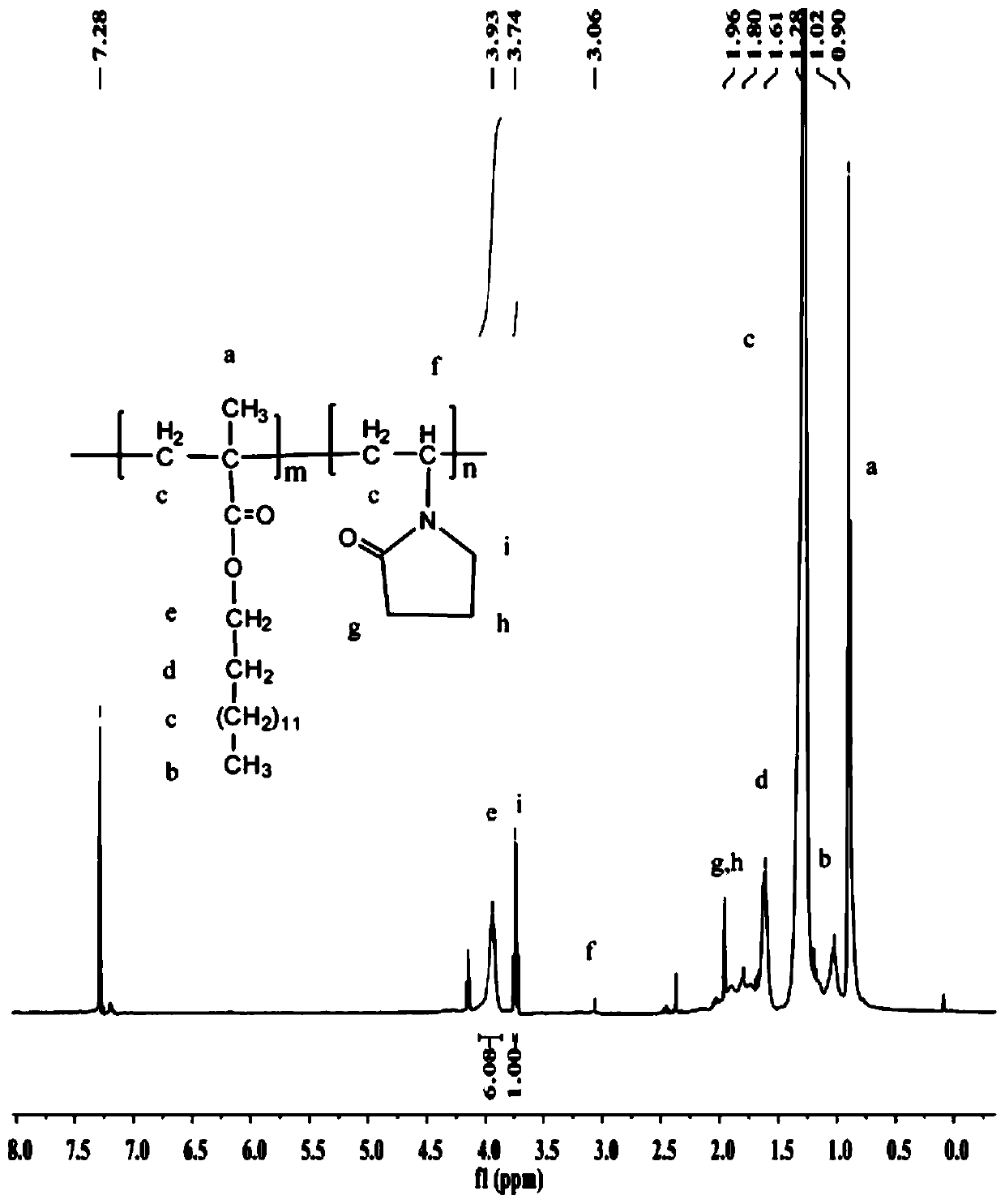

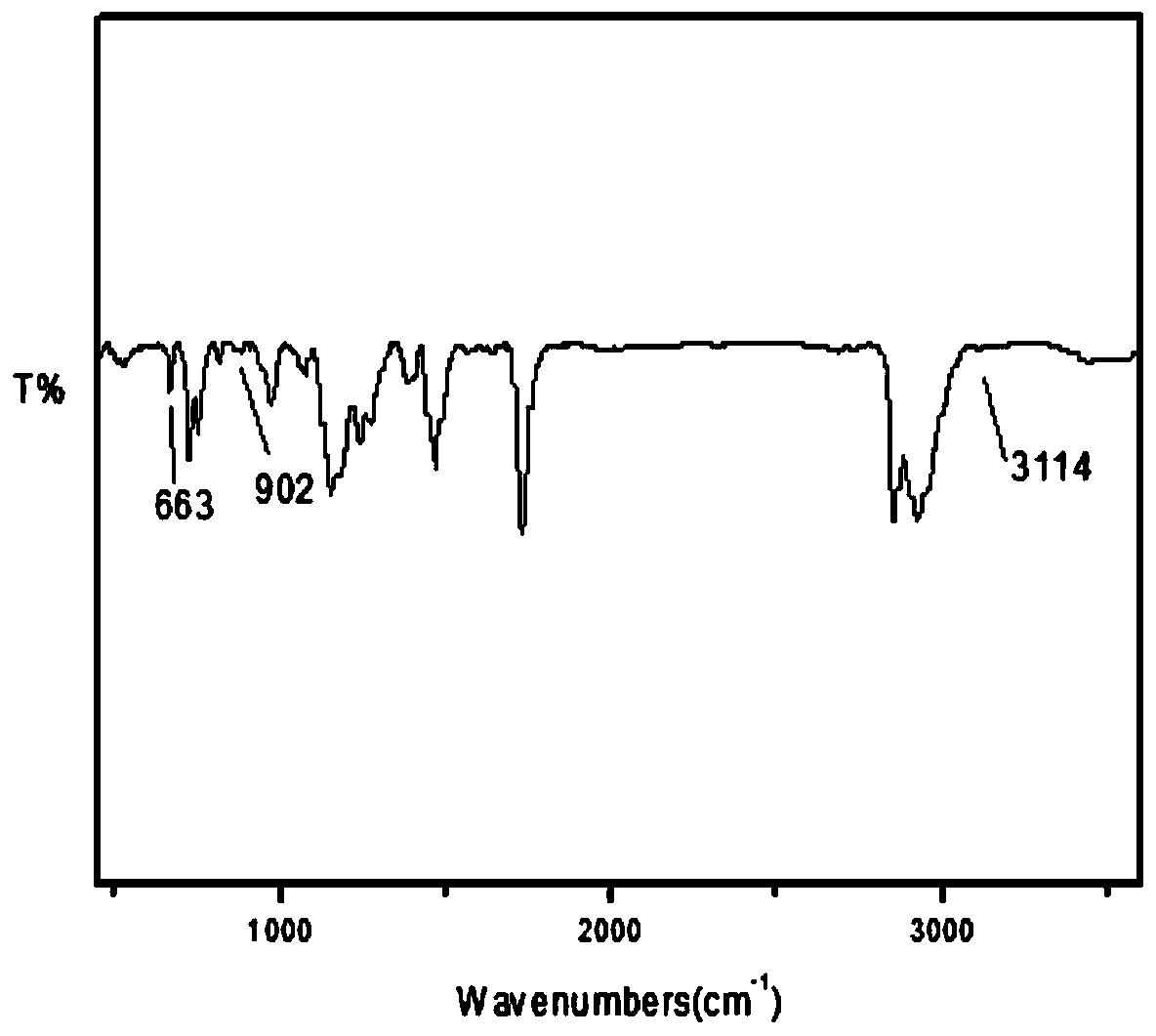

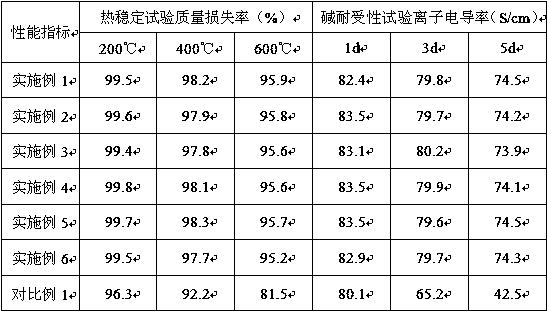

A hydroxide ion exchange membrane for preparing hydrogen for fuel cells and a preparation method thereof

InactiveCN109004253AGood effectImprove toleranceFinal product manufactureFuel cellsAcrylonitrileMechanical property

The invention belongs to the technical field of fuel cells, and provides a hydroxide ion exchange membrane for preparing hydrogen for fuel cells and a preparation method thereof. The method comprisescoupling a N-vinylimidazole with methyl iodide to alkylate N-vinylimidazole, copolymerization of styrene and acrylonitrile under ultrasonic vibration, crosslinking reaction with alkylated imidazole, and replacement of iodine with hydroxyl by sodium hydroxide. Compared with the traditional method, the prepared hydroxide ion exchange membrane of the present invention, At that same time, the raw material is environmentally friendly and pollution-free, the membrane can be directly synthesize at one time without subsequent membrane formation, the preparation process is simple, the conductivity andthe mechanical property are easy to control, and the membrane is suitable for large-scale industrial production. The invention has excellent hydrophilicity and the anion transmission rate, and remarkably improves the alkali tolerance and stability of the membrane material, and the raw material is environmentally friendly and pollution-free, and the membrane can be directly synthesized at one time.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Use of a composition containing at least one oxidation-sensitive hydrophilic active principle and at least one N-vinylmidazole polymer or copolymer

InactiveUS20030133889A1Maintain good propertiesLoss of elasticityPowder deliveryCosmetic preparationsUltravioletAcoric acid

The invention relates to the use of a composition containing, in a physiologically acceptable medium having an aqueous phase, at least one oxidation-sensitive hydrophilic active principle selected from the group consisting of ascorbic acid and its derivatives and at least one non-crosslinked N-vinylimidazole polymer or copolymer, the active principle and the polymer or copolymer both being in the aqueous phase, for preventing or combatting the harmful effects of UV radiation and / or of pollution on the skin, in particular loss of firmness and / or of elasticity of the skin.

Owner:LOREAL SA

Wheel and tire cleaner composition comprising an ethoxylated quaternary ammonium surfactant

InactiveUS7119053B2Easy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBetaineEngineering

An aqueous wheel cleaning solution for removing the dirt form the surface of aluminum, chrome, stainless steel, painted steel, painted aluminum, clear coated aluminum, rubber, and plastic wheels and tires without scrubbing by applying the cleaning solution to the wheel and / or tire then rinsing the wheel and / or tire with water. Selected polymers include a polyvinylpyrrolidone, a poly(N-vinylimidazole, a poly(4-vinylpyridine-betaine), and / or a poly(4-vinylpyridine-N-oxide) each one of which can be used with conventional wheel cleaning components such as an acid or alkaline-based cleaning formulation to dramatically improve its wheel cleaning power. These polymers can attach to organic and inorganic dirt particles forming a complex with them for easy removal from the wheel and / or tire during rinsing, leaving the wheel and / or tire clean without scrubbing the wheel or tire surface.

Owner:NITEO PROD LLC

Self-emulsifying aqueous low-temperature epoxy resin curing agent based on heterocyclic compound

ActiveCN109280154AFast dryingOvercome the disadvantage of slow curing speedEpoxy resin coatingsEpoxyRoom temperature

The invention relates to a self-emulsifying aqueous low-temperature epoxy resin curing agent based on a heterocyclic compound, and a formula comprises: 6-10 parts of N-vinylimidazole, 3-5 parts of aminoalkyl acrylate, 1-2 parts of N-vinylpyrrolidone, 1-2 parts of a reactive emulsifier, 15-30 parts of water, 0.05-0.1 part of an initiator, 0.02-0.05 part of a chain transfer agent, and 3-5 parts of ethanol. The curing agent of the invention can perform at a low temperature, has a high drying speed at normal temperature, overcomes the shortcoming of slow curing speed of a conventional aqueous curing agent / epoxy resin system; and the cured epoxy resin has high hardness.

Owner:广州飞思合成材料有限公司

Compounded diesel pour point depressant, and preparation method and application thereof

ActiveCN110093193AAvoid situations of reduced solubilityGuaranteed low temperature fluidityLiquid carbonaceous fuelsFuel additivesNitrogenCold filter plugging point

The invention relates to a compounded diesel pour point depressant, and a preparation method and an application thereof. The compounded diesel pour point depressant comprises, by weight, 20-80 parts of a polar nitrogen-containing compound and 20-80 parts of a tetradecyl methacrylate-N-vinylimidazole pour point depressant. The compounded diesel pour point depressant is prepared by uniformly mixingthe polar nitrogen-containing compound with the tetramethyl methacrylate-N-vinylimidazole pour point depressant. The compounded diesel pour point depressant is added to diesel when applied, and the mass percentage content of the compounded diesel pour point depressant in the diesel is 0.1-0.5%. Compared with diesel pour point depressants in the prior art, the compounded diesel pour point depressant of the present invention contains the polar nitrogen-containing compound, can reduce the condensation point of the diesel by 14-18 DEG C and reduce the cold filter plugging point by 6-8 DEG C in test after being added to the diesel, solves the problem of poor effect of the diesel pour point depressants at a low temperature, and can further improve the low temperature fluidity of the diesel and improve the low temperature flowing performance.

Owner:SHANGHAI INST OF TECH

Metallic ion-polyvinyl imidazol complex catalyst and preparation method and application thereof

InactiveCN101544755BIncrease local concentrationSolve the problem of low catalytic efficiencyEthylene HomopolymersWater soluble

The invention discloses a metallic ion-polyvinyl imidazole complex catalyst, which is a complex of a metallic ion and a polyvinyl imidazole ligand, wherein the molar ratio of imidazole groups to the metallic ion is 0.5 to 300; the metallic ion is a copper ion or manganese ion; and the polyvinyl imidazole ligand is a homopolymer of a N-vinyl imidazole monomer or copolymer of the N-vinyl imidazole monomer and another one or various water-soluble monomers and has a weight average molecular weight of 10<3> to 10<7>. The polyvinyl imidazole ligand has a large number of imidazole groups and can significantly increase the local concentration of the catalyst in a reaction medium after the complexation with the metallic ion, so the catalyst has greatly improved catalytic efficiency, achieves high PPO yield with a very small dosage when used in the preparation of PPO in a water medium, and solves the problem of the low catalytic efficiency of the prior polyphenylether catalyst prepared in the water medium.

Owner:ZHEJIANG UNIV

Method for environmentally-friendly and efficient production of electrolytic metal manganese and electrolytic additive

ActiveCN105603454AImprove current efficiencyReduce solubilityPhotography auxillary processesElectrolytic agentSolubility

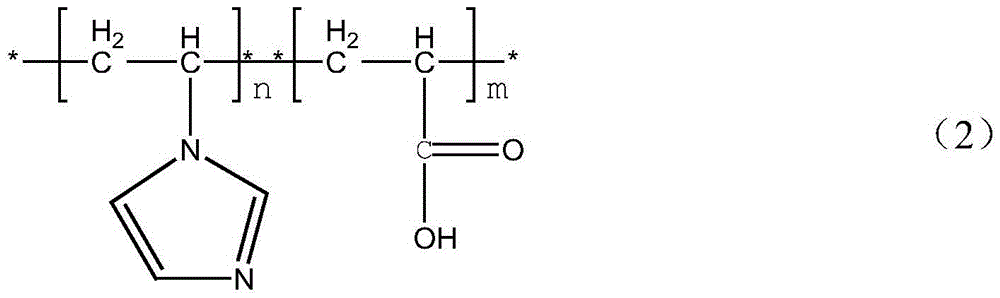

This invention belongs to the technical field of chemical production and provides a method for environmentally-friendly and efficient production of electrolytic metal manganese and an electrolytic additive. A poly N-vinyl imidazole and N-vinyl imidazole-acrylic copolymer is used as an electrolysis additive and is added to the electrolyte containing manganese sulfate and ammonium sulfate for electrolytic manganese production when being used, and the content of the electrolysis additive in the electrolyte is controlled to be 1 to 40 mg / L. The electrolysis additive is an environmentally-friendly non-toxic polymer, can be used for replacing currently and widely used toxic or pollution-carrying selenium dioxide and sulfur dioxide, is very small in solubility, does not accumulate in the electrolyte and is simple to operate in the production process, the metal manganese electrolysis efficiency is high, the product purity is high, the electrolytic process is stable, the purity requirement for the electrolyte is lower, the difficulty and the cost of electrolytic metal manganese production are reduced, and the electrolytic metal manganese has higher promotion and application value.

Owner:湖南东方矿业有限责任公司

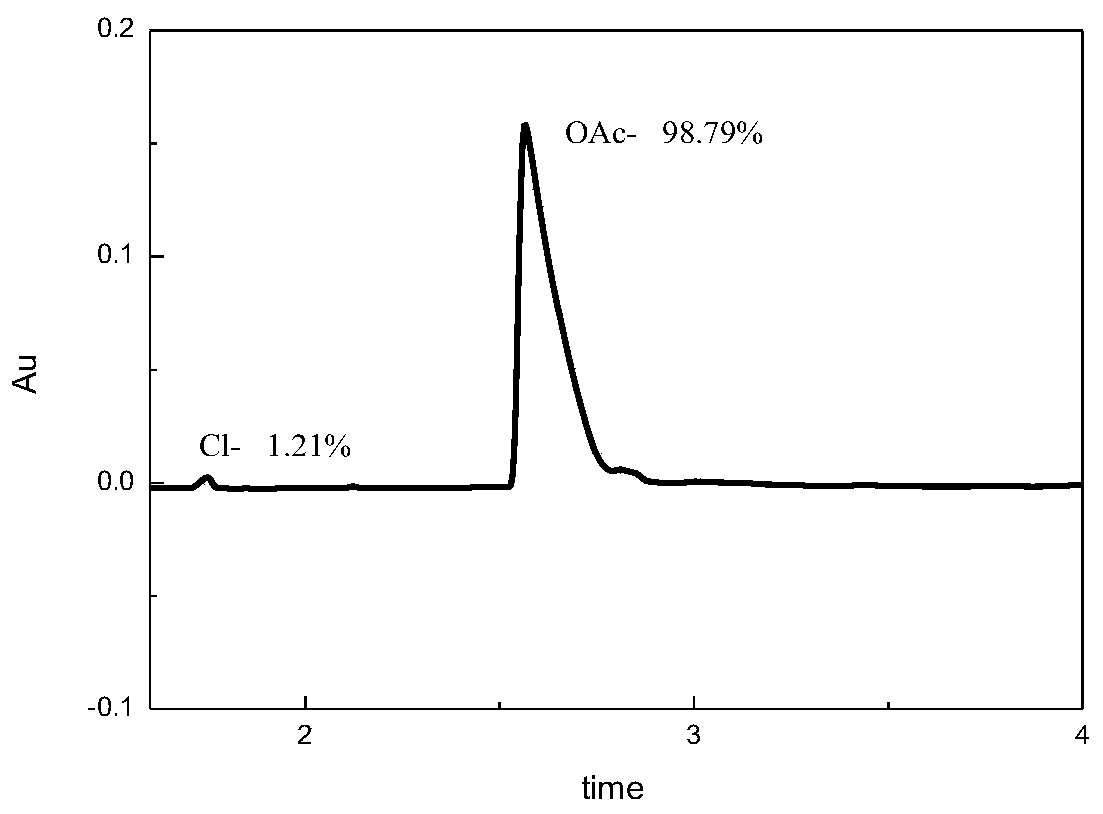

Imidazole ionic liquid and synthesis method and application thereof

ActiveCN109912507AImprove solubilityLess impuritiesCarboxylic acid salt preparationCelluloseSynthesis methods

The invention provides a synthesis method of imidazole ionic liquid 1-allyl-3-vinylimidazole acetate. The synthesis method comprises the following steps: carrying out one-step reaction on N-vinylimidazole and allyl chloride to obtain an ionic liquid intermediate 1-allyl-3-vinylimidazole chloride salt at first, and then carrying out anion exchange on the intermediate and potassium acetate to obtain1-allyl-3-vinylimidazole acetate ([AVIM] [OAc]). The ionic liquid 1-allyl-3-vinyl imidazole acetate can be used as a solvent and can be used for dissolving biological macromolecules such as starch and cellulose.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Magnetic supported catalyst and application thereof in preparing polyphenyleneoxide in aqueous medium

InactiveCN102060990BLarge specific surface areaHigh catalytic efficiencyChemical recyclingWater solublePolyphenyl ether

The invention discloses a magnetic supported catalyst, which is a complex of a nano magnetic particle surface grafted polyvinyl imidazol ligand and metal ions. A molar ratio of imidazol groups to the metal ions in the complex is (0.5-300):1; and the polyvinyl imidazol ligand is homopolymer of N-polyvinyl imidazol monomers or copolymer of N-polyvinyl imidazol monomers and one or more types of water-soluble monomers. The catalyst has high catalytic efficiency, and can be separated from a reaction medium by applying a magnetic field, so that the catalyst is recycled, and solves the problem that the conventional catalyst has low catalytic efficiency of preparing polyphenyleneoxide (PPO) in a reaction medium, particularly in an aqueous medium, and is difficult to recycle. The invention also discloses a preparation method and application of the magnetic supported catalyst. The preparation method is easy to operate and control, and is suitable for industrial production.

Owner:ZHEJIANG UNIV

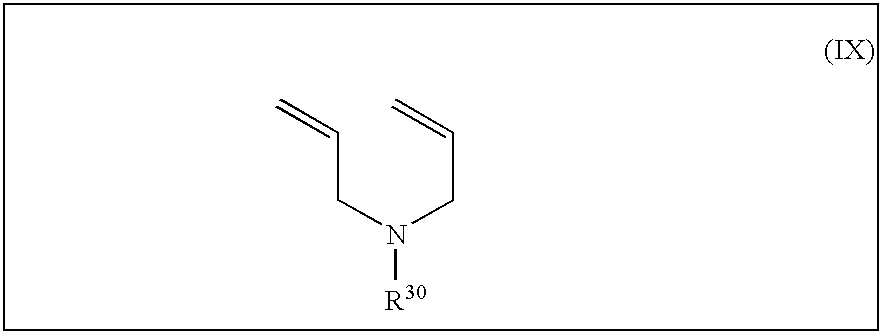

Cosmetic or dermatological sunscreens

The invention relates to mixtures comprising A) at least one copolymer obtainable by (i) free-radically initiated solution polymerization of a monomer mixture of (a) 0.01 to 99.99% by weight of at least one monomer chosen from the group consisting of N-vinylimidazoles and diallylamines, optionally in partially or completely quaternized form; (b) 0.01 to 99.99% by weight of at least one neutral or basic water-soluble monomer which is different from (a); (c) 0 to 50% by weight of at least one unsaturated acid or an unsaturated anhydride; (d) 0 to 50% by weight of at least one free-radically copolymerizable monomer which is different from (a), (b) and (c); and (e) 0 to 10% by weight of at least one monomer having at least two ethylenically unsaturated nonconjugated double bonds which acts as crosslinker, and (ii) subsequent partial or complete quaternization or protonation of the polymer where the monomer (a) is not quaternized or only partially quaternized and B) at least one inorganic UV filter and to the use thereof for the preparation of cosmetic or dermatological light protection agent preparations.

Owner:BASF AG

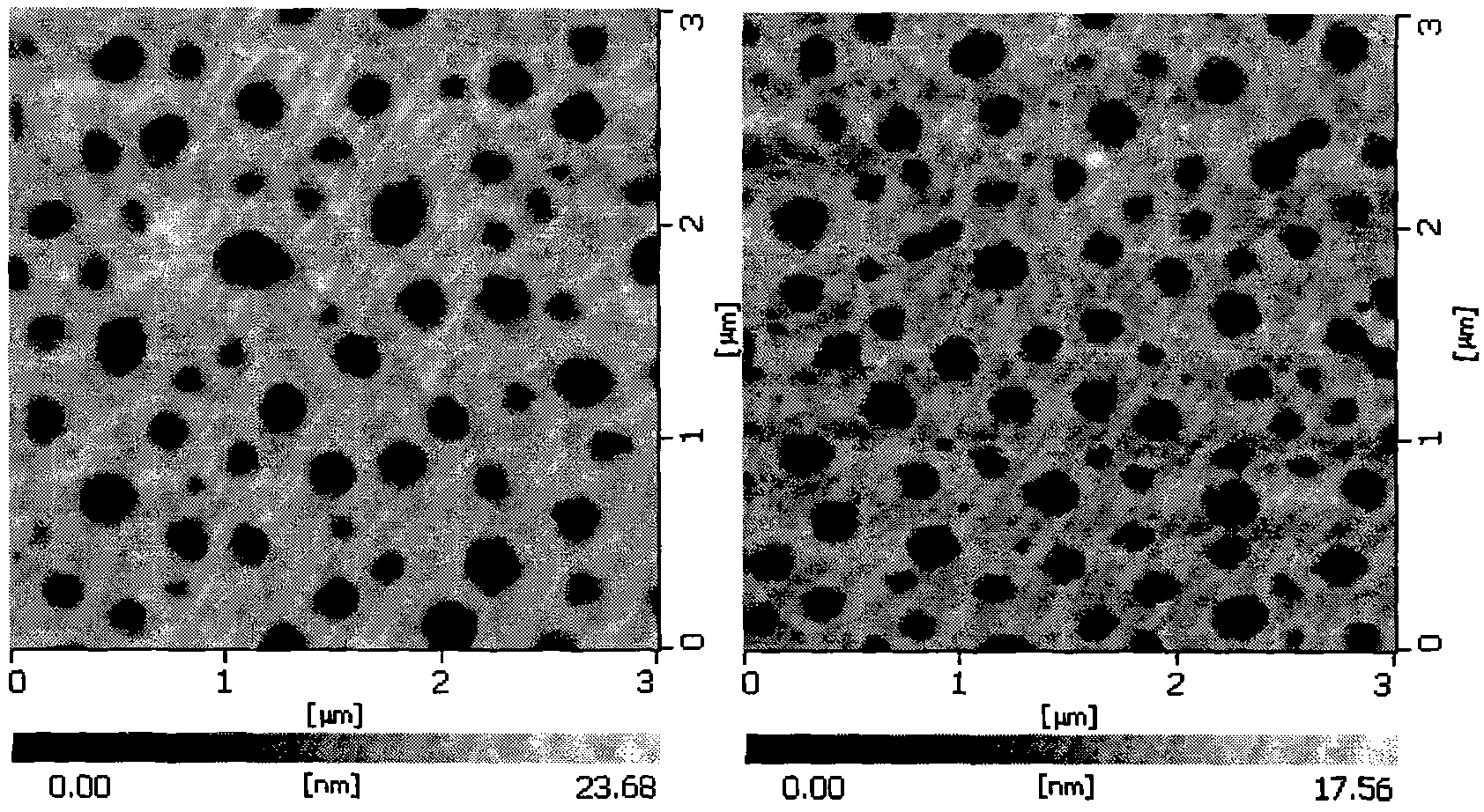

Method for preparing pressure retarded osmosis membrane modified by zwitterionic random copolymer

ActiveCN110354692AEasy to synthesizeMild conditionsSemi-permeable membranesSolubilityPolymer science

The invention relates to a method for preparing a pressure retarded osmosis membrane modified by a zwitterionic random copolymer. The method comprises the steps that methyl-2-[methyl-(4-pyridine)dithiocarbonate]propionate is used as a chain transfer agent, azobisisobutyronitrile is used as an initiator, N-vinylimidazole and an N-vinylphthalimide monomer containing an amino protecting group are subjected to random copolymerization; a poly N-vinylimidazole chain segment is subjected to quaternization under the action of propane sultone and 4-bromobutyric acid separately; under the action of hydrazine hydrate, a poly(N-vinylphthalimide)chain segment is subjected to amino deprotection to obtain a zwitterionic polymer; and the zwitterionic polymer is prepared into an aqueous solution to be grafted and modified on a porous support layer of an osmosis composite membrane. A comonomer used in the method is simple and easy to obtain, the random copolymer is convenient to synthesize, the condition is mild, and realization is easy; the chemical stability and water solubility of a graft polymer are improved, and the cost is greatly reduced; and excellent anti-protein and microbial adhesion areachieved.

Owner:SHENZHEN RES INST OF WUHAN UNIVERISTY

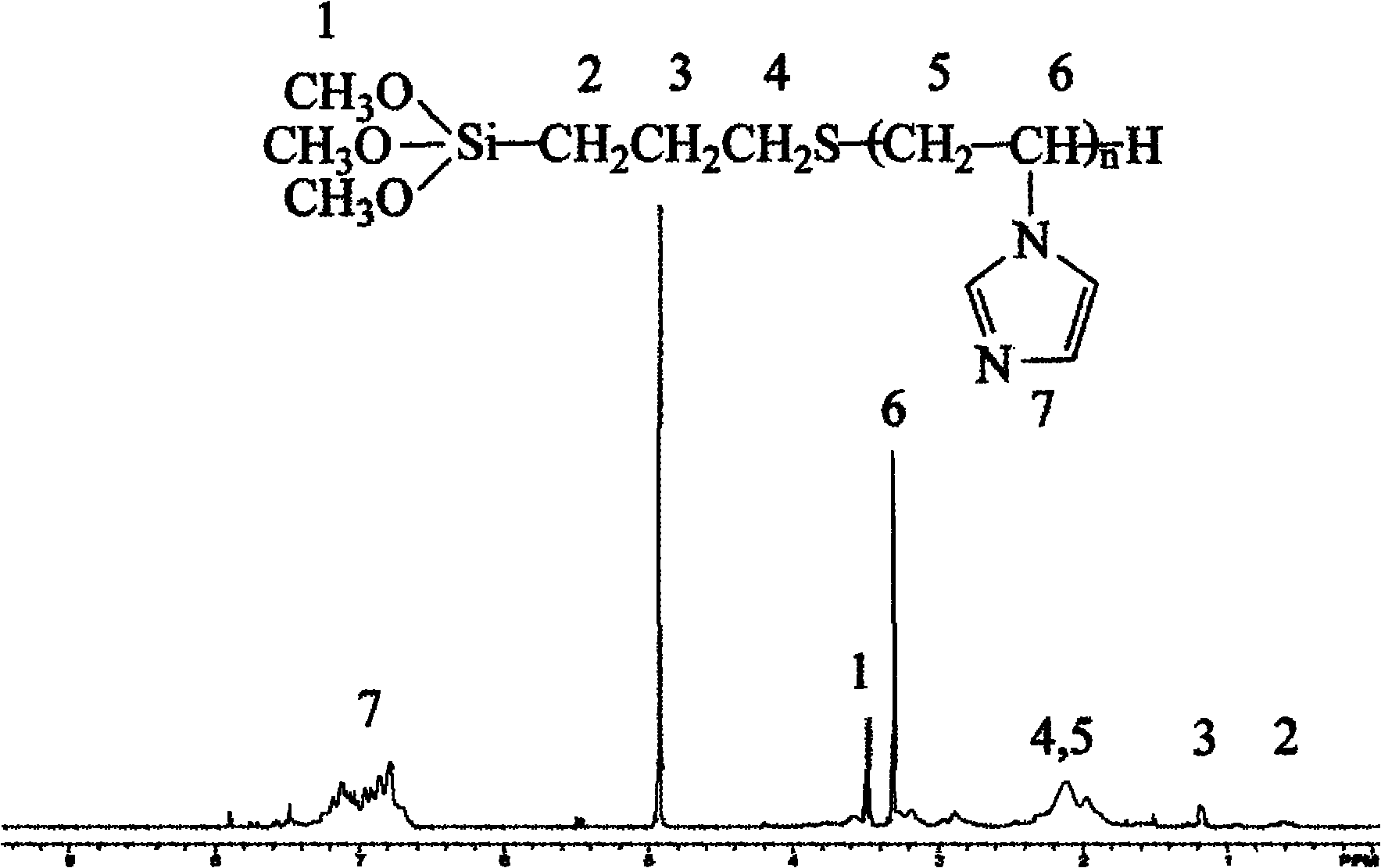

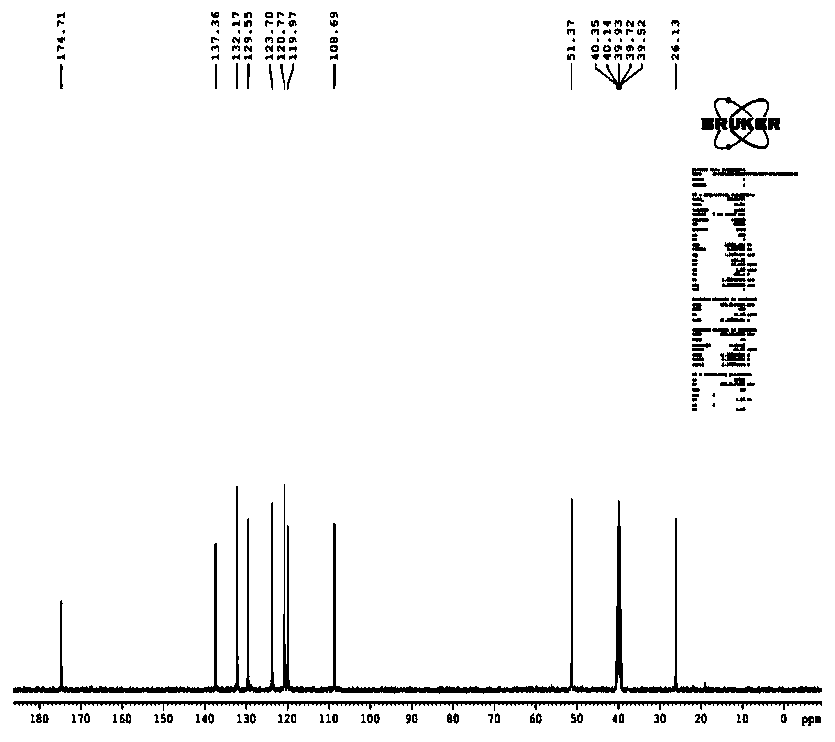

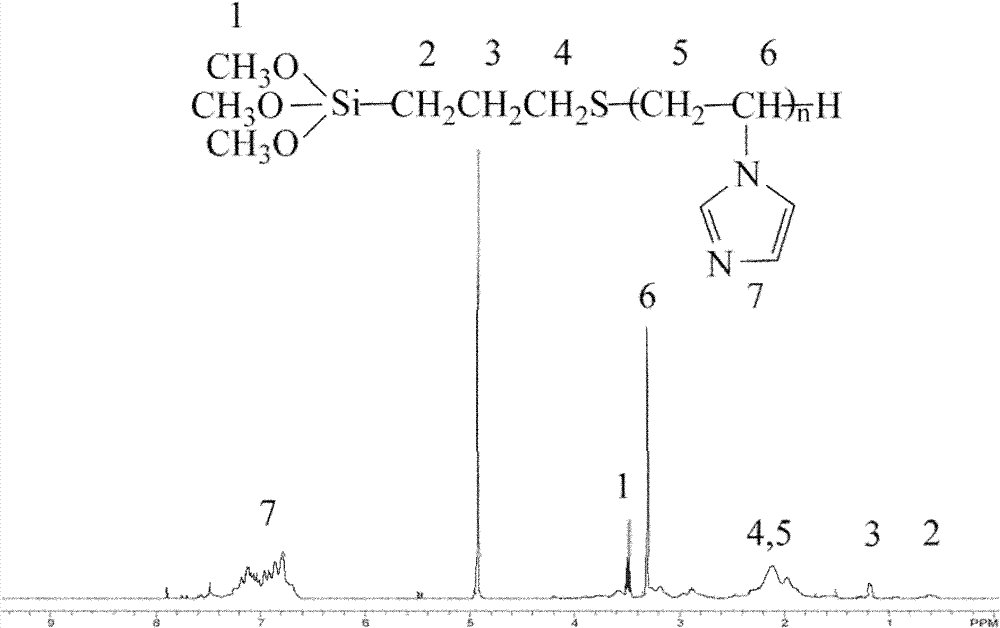

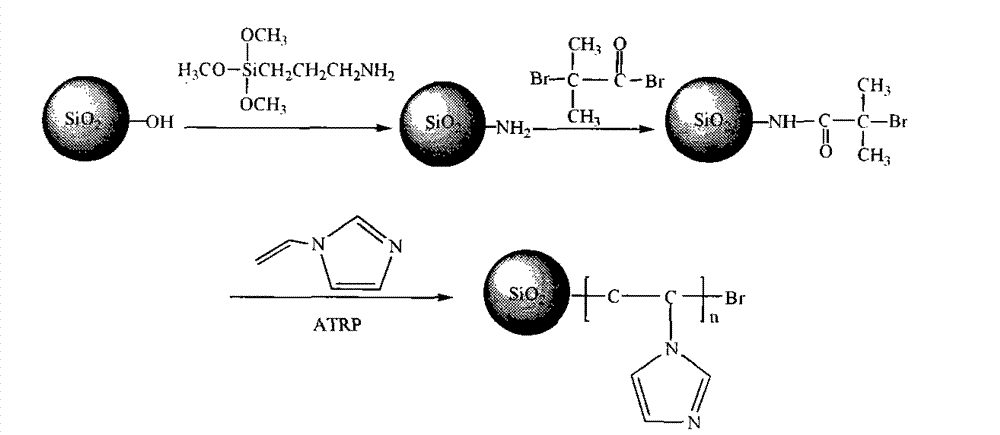

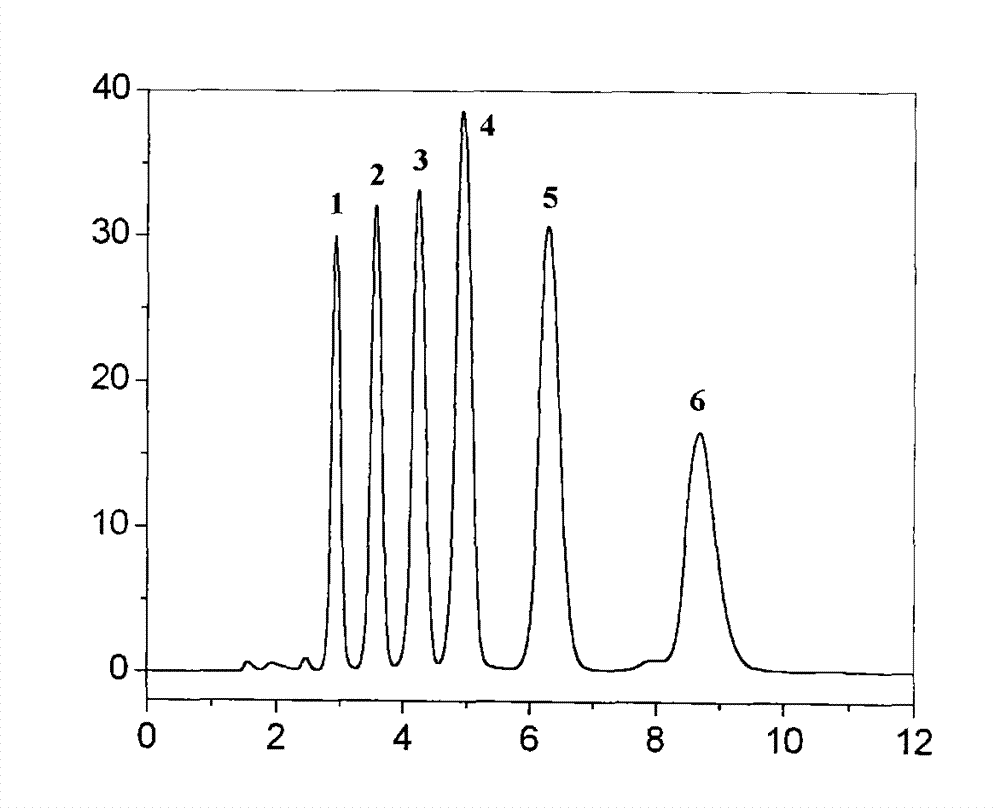

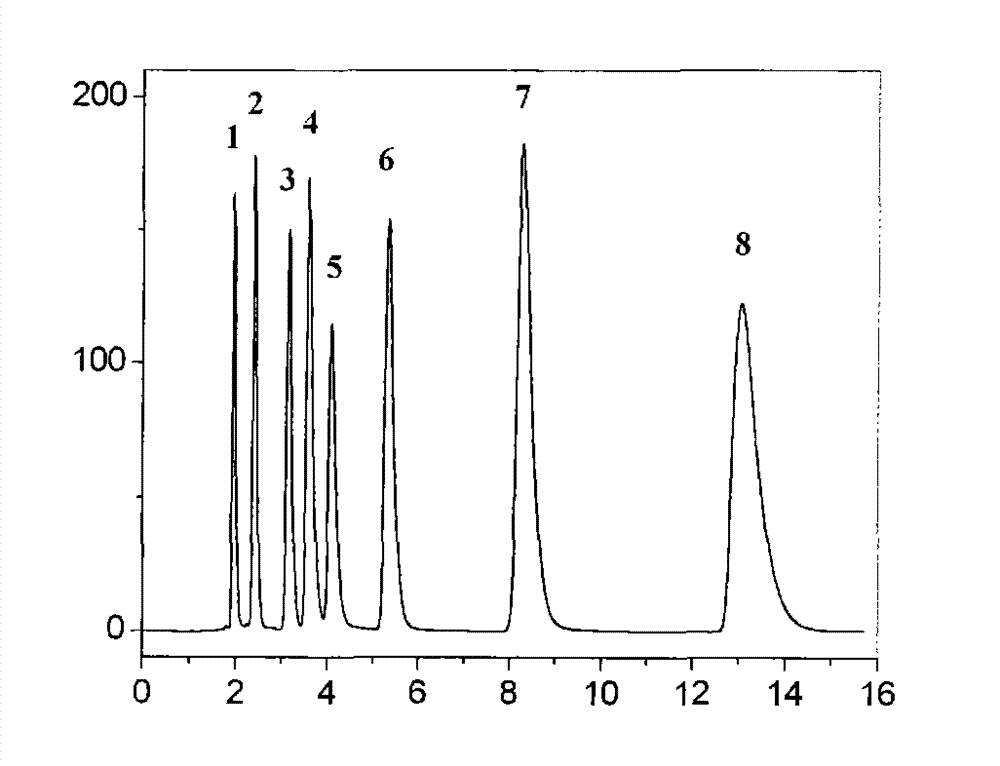

Method for preparing polyvinyl imidazole type silica gel filler

InactiveCN102101043BUniform thicknessThickness is easy to controlOther chemical processesIon chromatographyAtom-transfer radical-polymerization

The invention discloses a method for preparing a high-efficiency liquid-phase chromatogram filler, in particular to a method for preparing a polyvinyl imidazole type silica gel filler by an atom transfer free radical polymerization technique. The method comprises the following steps of: bromizing full porous spherical silica gel modified by an aminopropyl silanization reagent to prepare bromized silica gel; and performing atom transfer free radical polymerization on the bromized silica gel and N-vinylimidazole to generate polyN-vinylimidazole grafted silica gel. The filler has the advantages of uniform thickness of a polymerized layer, controllability, multiple action mechanism, capacity of separating many kinds of substances under the same chromatographic mode, separation under inverse phase, normal phase and ion chromatography modes, high selectivity and stability, symmetrical peak shape, high column efficiency, large column capacity, good application potential and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com