Self-emulsifying aqueous low-temperature epoxy resin curing agent based on heterocyclic compound

A technology for epoxy resin curing and heterocyclic compounds, which is applied in the field of water-based synthesis, can solve the problems of high curing temperature and achieve the effects of high crosslinking density, good aging resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

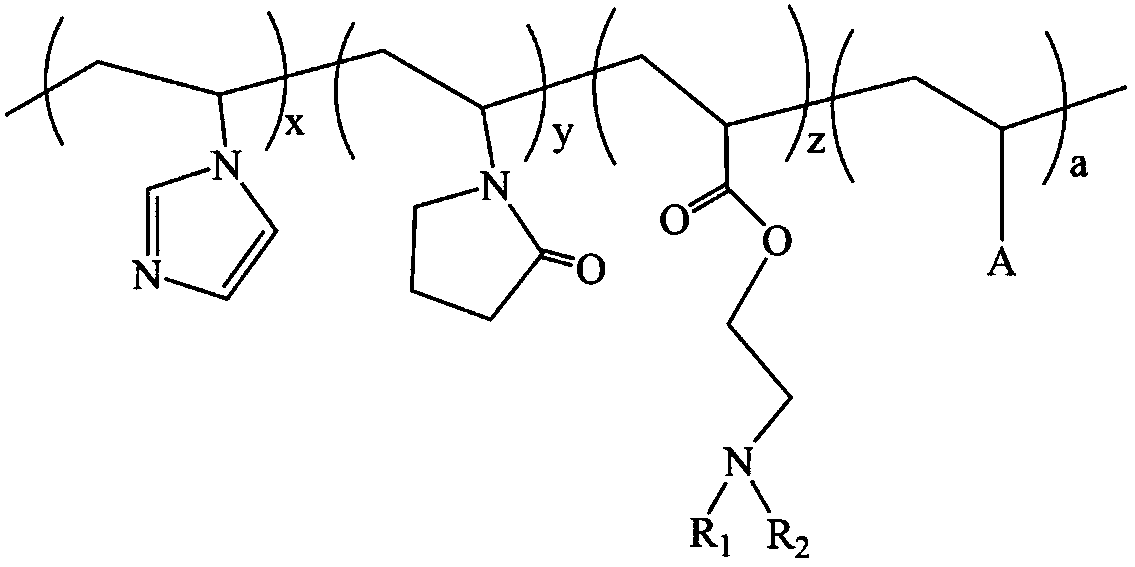

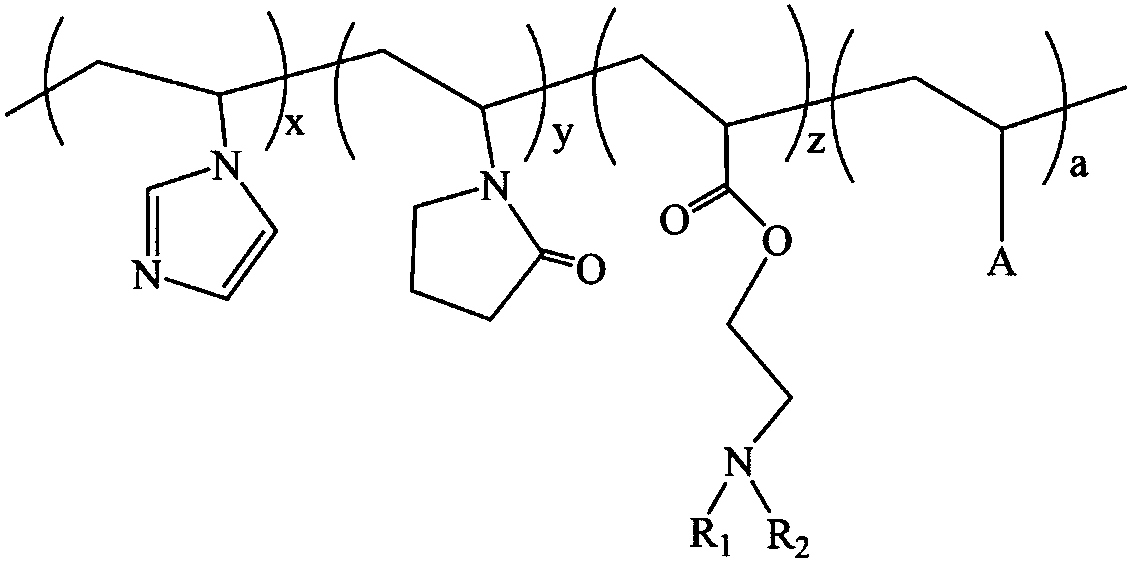

Method used

Image

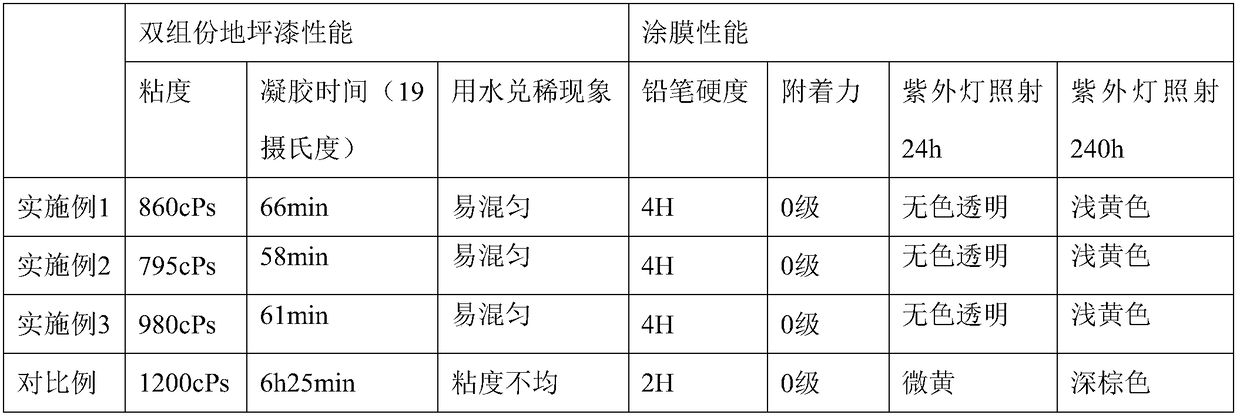

Examples

Embodiment 1

[0028] A self-emulsifying water-based low-temperature epoxy resin curing agent based on heterocyclic compounds. The formula for preparing the curing agent consists of 10 parts of N-vinylimidazole and 3 parts of aminoethyl methacrylate in parts by weight. , 2 parts of N-vinylpyrrolidone, 1 part of sodium dodecyl allyl succinate sulfonate, 30 parts of water, 0.05 part of peroxybenzoic acid, 0.05 part of thioglycolic acid, 3 parts of ethanol;

[0029] Wherein, the preparation method of described curing agent is:

[0030] Under the condition of blowing nitrogen, add the formula amount of water into the reactor, stir and raise the temperature to 110°C, then add the formula amount of N-vinylimidazole, the formula amount of aminoethyl methacrylate, and the formula amount of The mixture of N-vinylpyrrolidone, sodium dodecyl allyl succinate sulfonate, 90% benzoic acid peroxide, 90% mercaptoacetic acid and ethanol in the formula quantity, the dropping time is In 1.5 hours, after the dr...

Embodiment 2

[0032] A self-emulsifying type water-based low-temperature epoxy resin curing agent based on heterocyclic compounds. The formula for preparing the curing agent consists of: 6 parts of N-vinylimidazole, dimethylaminoethyl methacrylate 5 parts of ester, 1 part of N-vinylpyrrolidone, 2 parts of 2-allyl ether 3-hydroxypropane-1-sulfonate sodium, 15 parts of water, 0.1 part of benzoyl peroxide, 0.02 part of mercaptopropionic acid, ethanol 5 copies;

[0033] Wherein, the preparation method of described curing agent is:

[0034] Under the condition of nitrogen, add the formula amount of water into the reactor, stir and raise the temperature to 105°C, then add the formula amount of N-vinylimidazole, formula amount of dimethylaminoethyl methacrylate, Formulated amount of N-vinylpyrrolidone, formulated amount of 2-allyl ether 3-hydroxypropane-1-sodium sulfonate, formulated amount of 90% benzoyl peroxide, formulated amount of 90% mercaptopropionic acid, ethanol The mixed solution, the ...

Embodiment 3

[0036] A self-emulsifying type water-based low-temperature epoxy resin curing agent based on heterocyclic compounds. The formula for preparing the curing agent consists of: 8 parts of N-vinylimidazole, methylaminoethyl methacrylate 4 parts, 1.5 parts of N-vinylpyrrolidone, 1.2 parts of styrylphenol polyoxyethylene ether, 19 parts of water, 0.06 parts of tert-butyl peroxybenzoate, 0.04 parts of mercaptoethanol, 4 parts of ethanol;

[0037] Wherein, the preparation method of described curing agent is:

[0038] Under the condition of nitrogen, add the formula amount of water into the reactor, stir and raise the temperature to 120°C, then add the formula amount of N-vinylimidazole, formula amount of methylaminoethyl methacrylate, formula N-vinylpyrrolidone, styrene-based phenol polyoxyethylene ether, 90% tert-butyl peroxybenzoate, 90% mercaptoethanol, ethanol mixture, the time for adding is In 1 hour, after the dropwise addition was completed, the reaction was continued for 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com