Polyimidazole ionic liquid based copolymer, and preparation method and application thereof

An ionic liquid, polyimidazole technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as high operating costs, secondary pollution, and complicated operations, and achieve low cost, large adsorption capacity, Good desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of polyimidazole ionic liquid-based copolymer

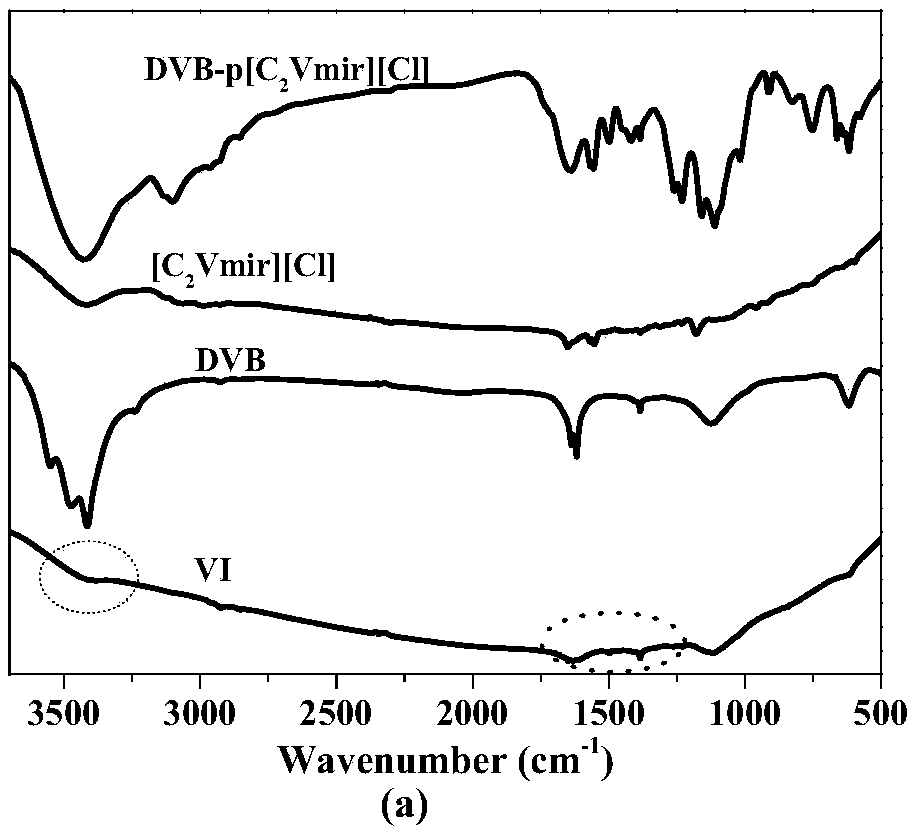

[0032] (1) Polyimidazole-based ionic liquid-based copolymer DVB-p[C 2 Vmir][Cl]

[0033]

[0034] The preparation method is as follows:

[0035] 1) Synthesis of imidazole-based ionic liquids: Take 4.706g N-vinylimidazole and 9.896g 1,2-dichloroethane into a 100mL single-necked flask, then add 40mL acetonitrile and mix well, react at 80°C for 9h to obtain a brown viscous Like liquid, remove acetonitrile with vacuum distillation, wash, purify to obtain intermediate product imidazoles ionic liquid [C 2 Vmir] [Cl].

[0036] 2) 4mL of the obtained [C 2 Add Vmir][Cl] into the three-necked flask, then add 0.02g N,N-methylenebisacrylamide (MBA), 0.3mL divinylbenzene (DVB), 40mL acetonitrile, ultrasonic 20min, then add 0.2g Potassium sulfate, react at 80°C for 24h, after cooling, suction filter, wash, purify, and vacuum dry to obtain polyimidazole ionic liquid-based copolymer DVB-p[C 2 Vmir] [Cl].

[0...

Embodiment 2

[0052] Example 2 Polyimidazole-based ionic liquid-based copolymer as an adsorbent to the recovery of rhenium

[0053] (1) Adsorption effect of polyimidazole-based ionic liquid-based copolymer adsorbents with different carbon chain lengths on Re(VII)

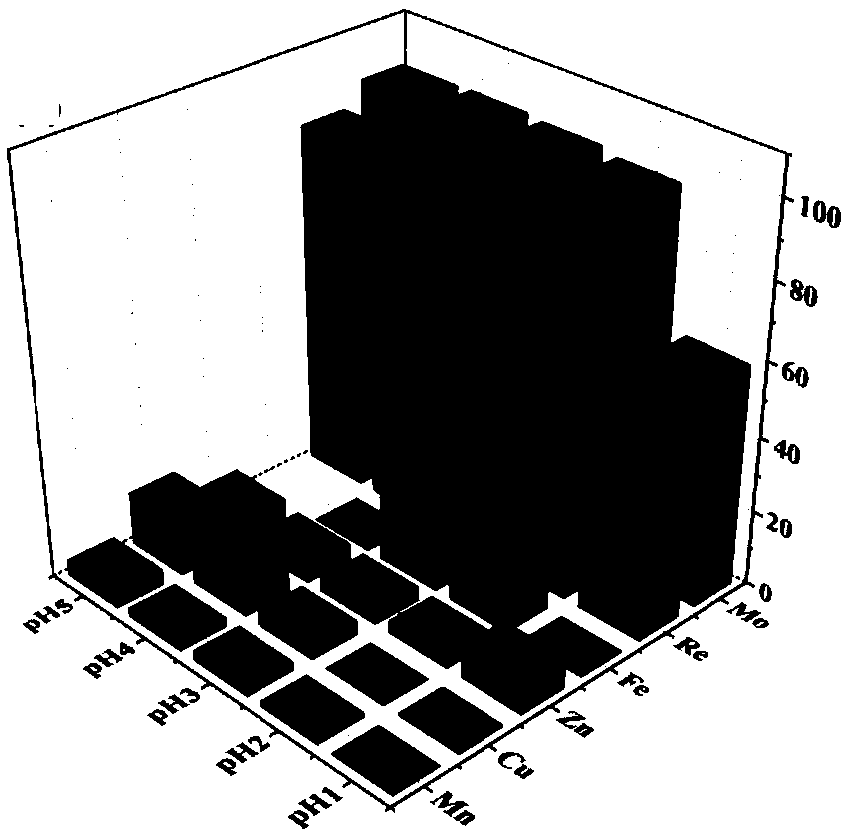

[0054] Method: get the polymer DVB-p[C prepared by 10mg embodiment 1 respectively 2 Vmir][Cl], DVB-p[C 4 Vmir][Cl], DVB-p[C 6 Vmir][Cl], add 5mL of different pH (pH=1,2,3,4,5,6,7) respectively, 20mg·L -1 The solution of Re(VII) was shaken in the shaking box for 8h, and the results were as follows: image 3 shown.

[0055] Depend on image 3 It can be seen that the adsorption capacity of the three adsorbents for Re(VII) is relatively low under high acidity conditions, which may be due to the Cl in the solution at higher acidity - The concentration is high, which is not conducive to the Cl on the adsorption material - with ReO 4 - Anion exchange occurs; at lower acidity, ReO 4 - The electrostatic attraction with the imid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com