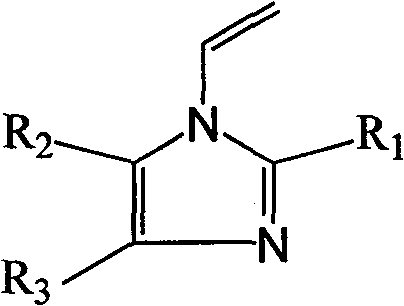

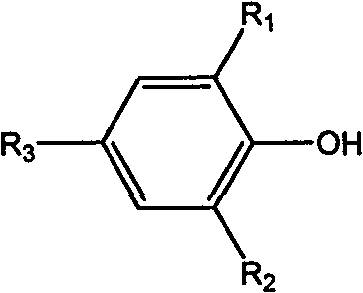

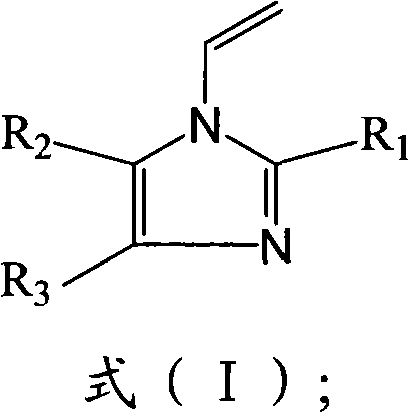

Metallic ion-polyvinyl imidazol complex catalyst and preparation method and application thereof

A technology of polyvinylimidazole and metal ions, applied in the field of metal ion-polyvinylimidazole complex catalysts and their preparation, metal-polyvinylimidazole complex catalysts in the field of preparing polyphenylene ethers in aqueous media , can solve the problems of large amount of catalyst and low catalytic efficiency, and achieve the effect of improved catalytic efficiency, low solution efficiency and increased local concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 prepares metal ion-polyvinylimidazole complex catalyst

[0048] Add 10 g of N-vinylimidazole, 0.1 g of azobisisobutyronitrile, and 100 mL of water into a reaction kettle connected with a thermometer, a stirring blade, a condenser tube, and a gas inlet and outlet, and stir to obtain a transparent solution. Under the protection of nitrogen atmosphere, the temperature of the reaction vessel was raised to 80° C., and the reaction was carried out for 6 hours. After the polymerization reaction was finished, the reaction solution was poured into toluene, and the polymer was precipitated out. After filtering, washing, and vacuum drying, 9.3g of polyvinylimidazole ligands were obtained, and the weight-average molecular weight was 8.0×10 4 .

[0049] 0.0086g CuCl 2 2H 2 O (the molar weight is 0.05mmol) and 0.0188g of the above-prepared polyvinylimidazole ligands (wherein, the imidazole group is 0.2mmol) were respectively dissolved in 5mL of water, mixed and stirre...

Embodiment 2~4

[0051] Except adopting the mixture of N-vinylimidazole monomer and water-soluble comonomer to replace N-vinylimidazole in Example 1, all the other operations are the same as in Example 1 to prepare metal ion-polyvinylimidazole complex Catalyst, see Table 1:

[0052] Table 1

[0053] Example

Embodiment 5~6

[0055] Except adopting potassium persulfate or tert-butyl hydroperoxide / sodium disulfide initiator system to replace the azobisisobutyronitrile in embodiment 1, all the other operations are the same as in embodiment 1 to prepare metal ion-polyvinylimidazole Complex catalyst, see table 2:

[0056] Table 2

[0057] Example serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com