Magnetic supported catalyst and application thereof in preparing polyphenyleneoxide in aqueous medium

A supported catalyst and magnetic technology, which is applied in the field of polymer metal complex catalysts, can solve the problems that the filtrate cannot be recycled, the catalyst cannot be recycled and reused, and the catalyst and polyphenylene ether products cannot be separated, so as to achieve high catalytic efficiency, Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1 Preparation of Magnetically Supported Polyvinylimidazole Ligand-Metal Ion Complex Catalyst

[0072] (1) Preparation of nano-ferric oxide

[0073] Prepare 250 mL of 0.5 mol / L sodium hydroxide aqueous solution and add it to a three-necked flask. Under the protection of nitrogen, the temperature was raised to 80°C. Prepare FeCl 3 ·6H 2 O concentration is 1mol / L, FeCl 2 4H 2 25 mL of an aqueous solution with an O concentration of 0.5 mol / L and an HCl concentration of 0.4 mol / L was added dropwise to the above aqueous sodium hydroxide solution under mechanical stirring at 1200 rpm. React for 30 minutes. After the reaction, wash with distilled water and ethanol for 5 times respectively, separate the obtained solid by applying an external magnetic field, and dry it in vacuum at room temperature for 24 hours to prepare black nanometer ferric oxide.

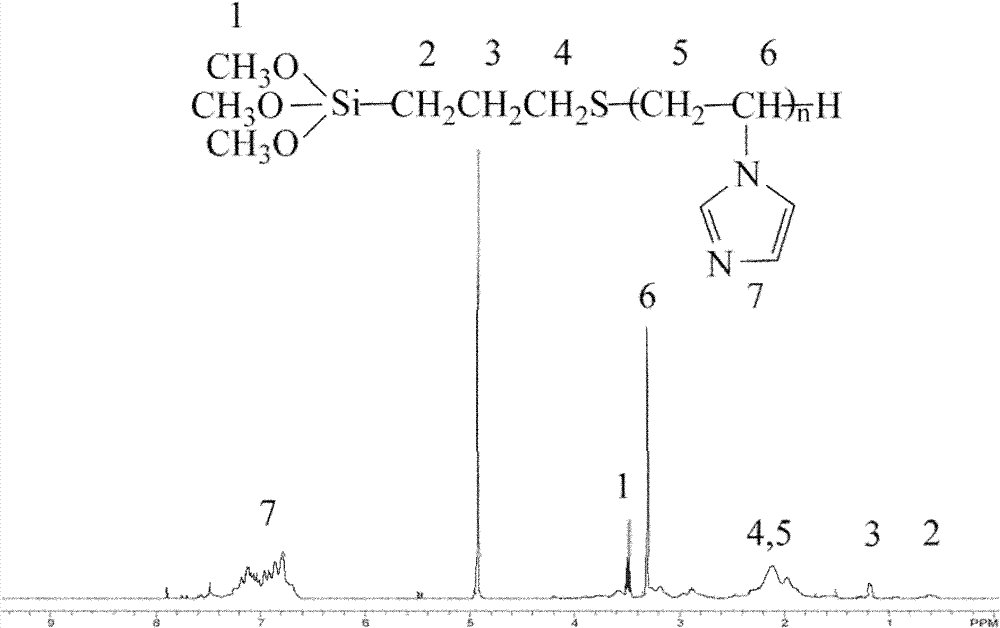

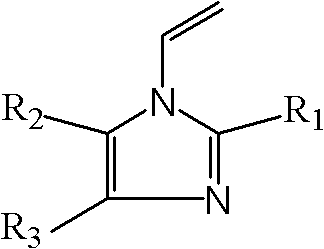

[0074] (2) Synthesis of polyvinylimidazole ligands with a silane coupling agent at one end

[0075] Dissolve 2.7...

Embodiment 2~4

[0082] Except that the mixture of N-vinylimidazole monomer and water-soluble comonomer is used to replace the N-vinylimidazole in Example 1, the rest of the operations are the same as in Example 1 to prepare polyethylene with a silane coupling agent at one end imidazole ligands, see Table 1 for specific parameters, and finally obtain a magnetically supported polyvinyl imidazole ligand-metal ion complex catalyst.

[0083] Table 1

[0084]

Embodiment 5~6

[0086] Except for changing the feeding ratio of N-vinylimidazole and 3-mercaptopropyltrimethoxysilane, the rest of the operations are the same as in Example 1 to prepare a polyvinylimidazole ligand with a silane coupling agent at one end. The specific parameters As shown in Table 2, a magnetically supported polyvinylimidazole ligand-metal ion complex catalyst was finally obtained.

[0087] Table 2

[0088] Example serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com