Ionic liquid and method for homogeneous phase-modified reed-reinforced PE (polyethylene) composite material thereof

A technology of ionic liquid and composite materials, which is applied in the field of homogeneously modified reed/PE composite materials, can solve the problems of poor processability and low mechanical strength, achieve the effects of reducing surface polarity, excellent processing performance, and improving solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

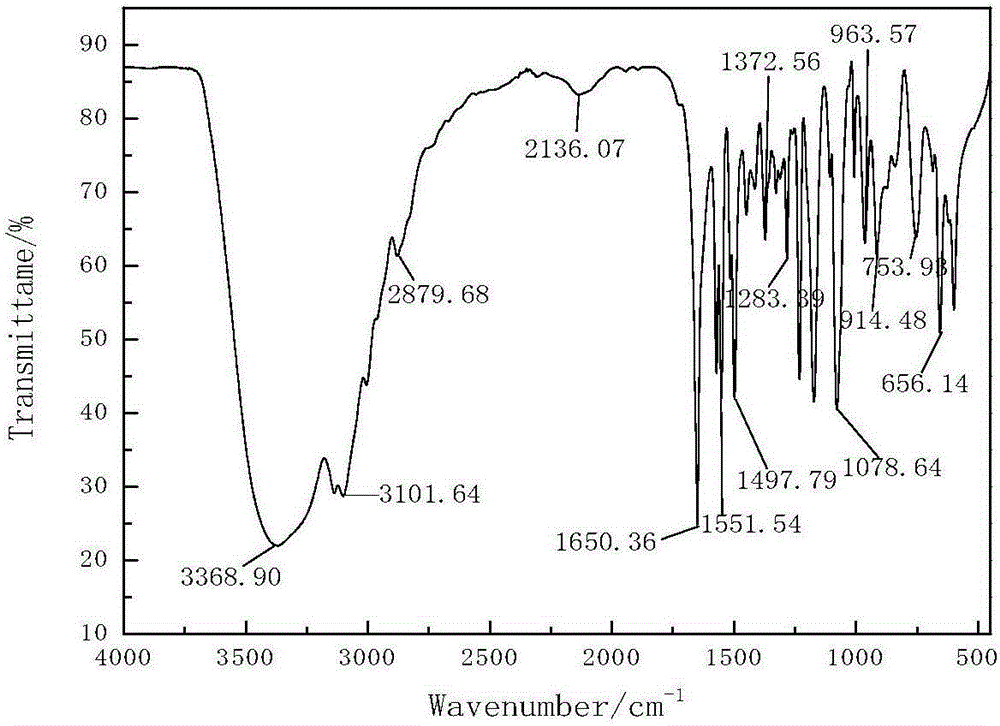

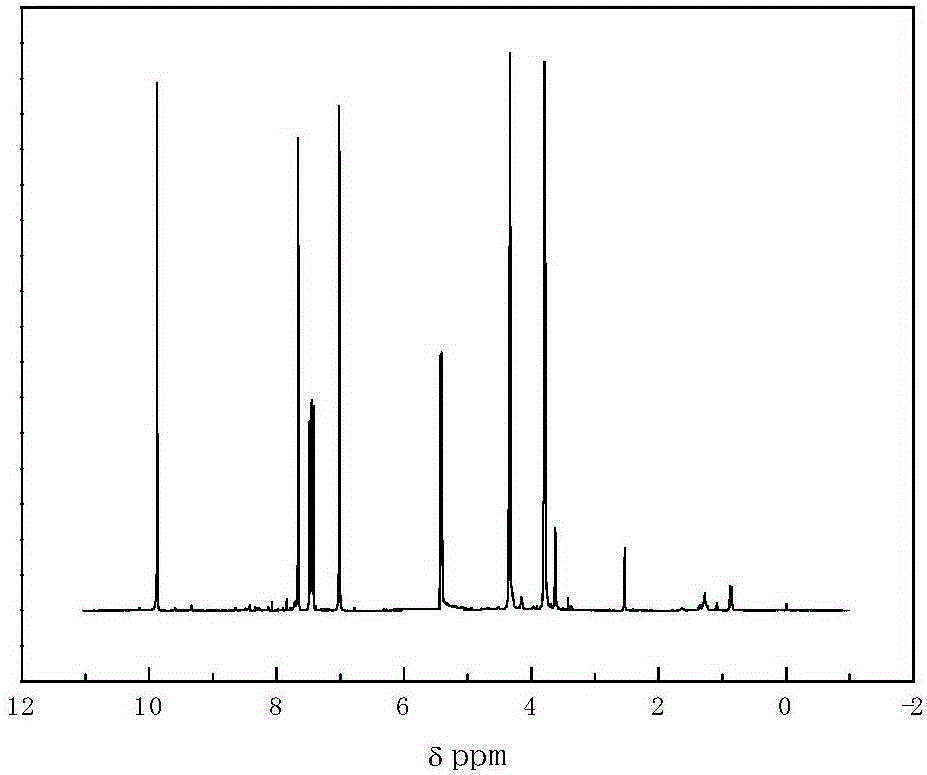

[0026] Ionic liquid synthesis method: Add N-vinylimidazole (0.60mol) into a 250ml four-neck flask, 90°C constant temperature oil bath, magnetic stirring, slowly drop 2-chloroethanol (0.60mol) into the flask under nitrogen protection During the reaction, the solution gradually changed from colorless to golden yellow. After continuous stirring for 10 h, the mixture was washed with ether for 3 times, and the synthesized golden yellow liquid was vacuum-dried in a vacuum oven at 80° C. for 12 h to obtain an ionic liquid.

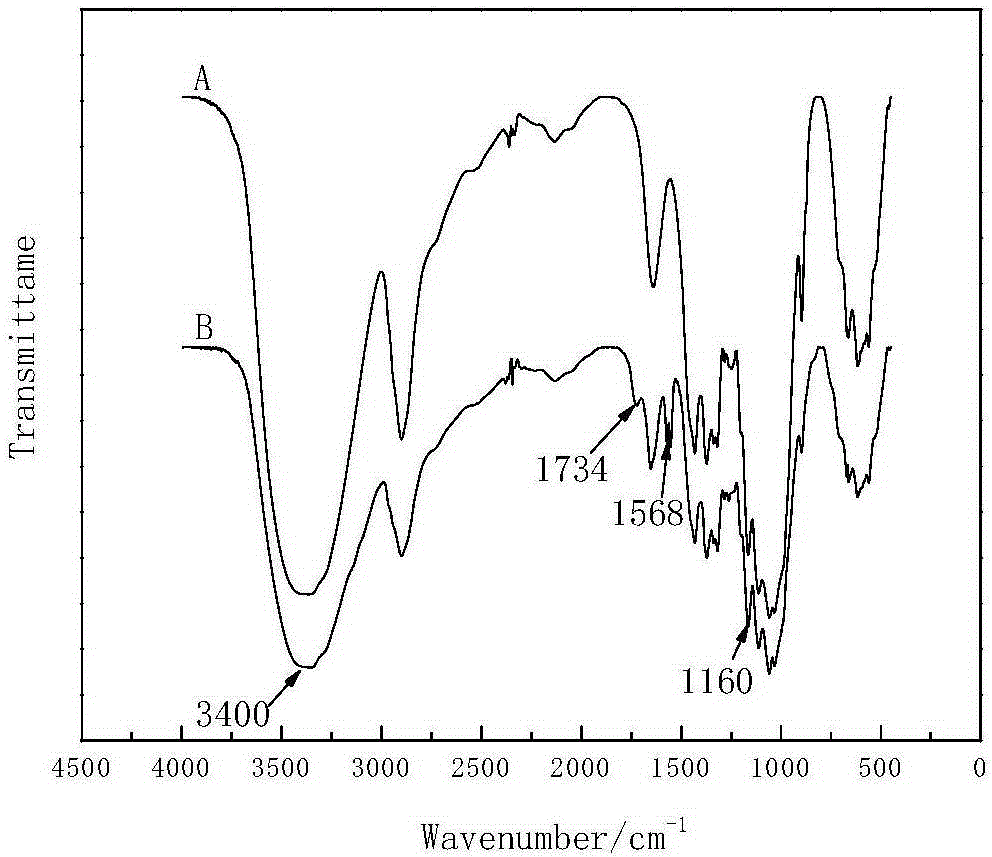

[0027] Homogeneously modified reed method: Add 10g of ionic liquid into a three-necked flask, place in a constant temperature oil bath at 100°C, and stir with magnetic force. Add the powdery reed into the three-necked flask several times, dissolve gradually under constant stirring, and prepare a solution with a mass fraction of 5%. Add 78.5g acetyl chloride, in N 2 Heating to 80°C under protection, stirring magnetically for a predetermined time, precipitated a ...

Embodiment 2

[0030] Ionic liquid synthesis method: Add N-vinylimidazole (0.60mol) into a 250ml four-neck flask, 90°C constant temperature oil bath, magnetic stirring, slowly drop 2-chloroethanol (0.550mol) into the flask under nitrogen protection During the reaction, the solution gradually changed from colorless to golden yellow. After continuous stirring for 10 h, it was washed with ether for 3 times, and the synthesized golden yellow liquid was vacuum-dried in a vacuum oven at 80° C. for 12 h.

[0031] Homogeneously modified reed method: Add 10g of ionic liquid into a three-necked flask, place in a constant temperature oil bath at 100°C, and stir with magnetic force. Add the powdery reed into the three-necked flask several times, dissolve gradually under constant stirring, and prepare a solution with a mass fraction of 5%. Add 78.5g acetyl chloride, in N 2 Heating to 80°C under protection, stirring magnetically for a predetermined time, precipitated a white product with methanol, filte...

Embodiment 3

[0034] Ionic liquid synthesis method: Add N-vinylimidazole (0.60mol) into a 250ml four-necked flask, 90°C constant temperature oil bath, magnetic stirring, slowly drop 2-chloroethanol (0.50mol) into the flask under nitrogen protection During the reaction, the solution gradually changed from colorless to golden yellow. After continuous stirring for 10 h, it was washed with ether for 3 times, and the synthesized golden yellow liquid was vacuum-dried in a vacuum oven at 80° C. for 12 h.

[0035] Homogeneously modified reed method: Add 10g of ionic liquid into a three-necked flask, place in a constant temperature oil bath at 100°C, and stir with magnetic force. Add the powdery reed into the three-necked flask several times, dissolve gradually under constant stirring, and prepare a solution with a mass fraction of 5%. Add 78.5g acetyl chloride, in N 2 Heating to 80°C under protection, stirring magnetically for a predetermined time, precipitated a white product with methanol, filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com