Functional polymer and preparation method and application thereof

A functional polymer technology, applied in material separation, instrumentation, analysis of materials, etc., can solve the problems of time-consuming, complex fluorescent molecular structure, and difficulty of sensing materials, etc., to achieve simple and clear synthesis routes, simple copolymer structures, The effect of high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

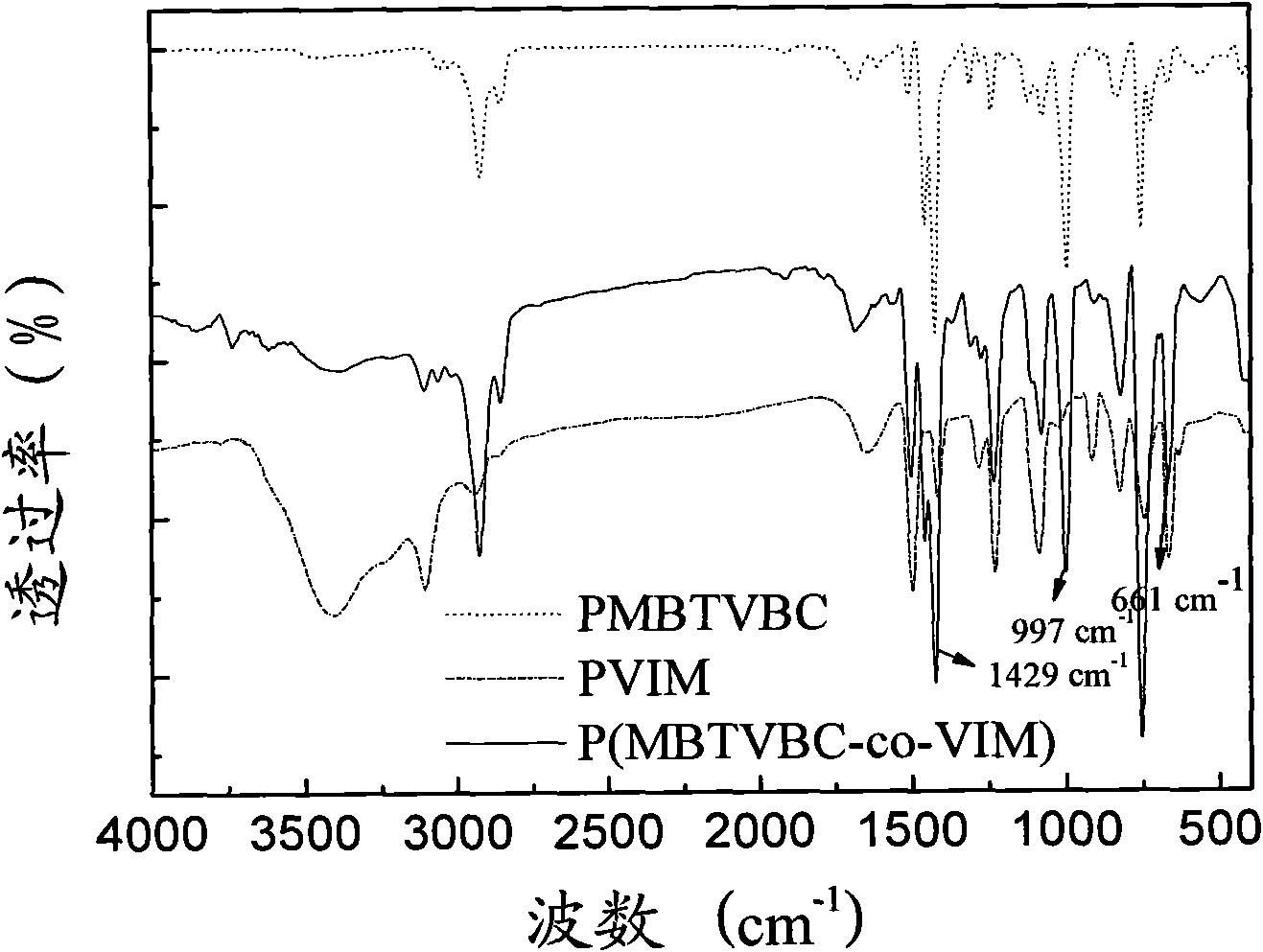

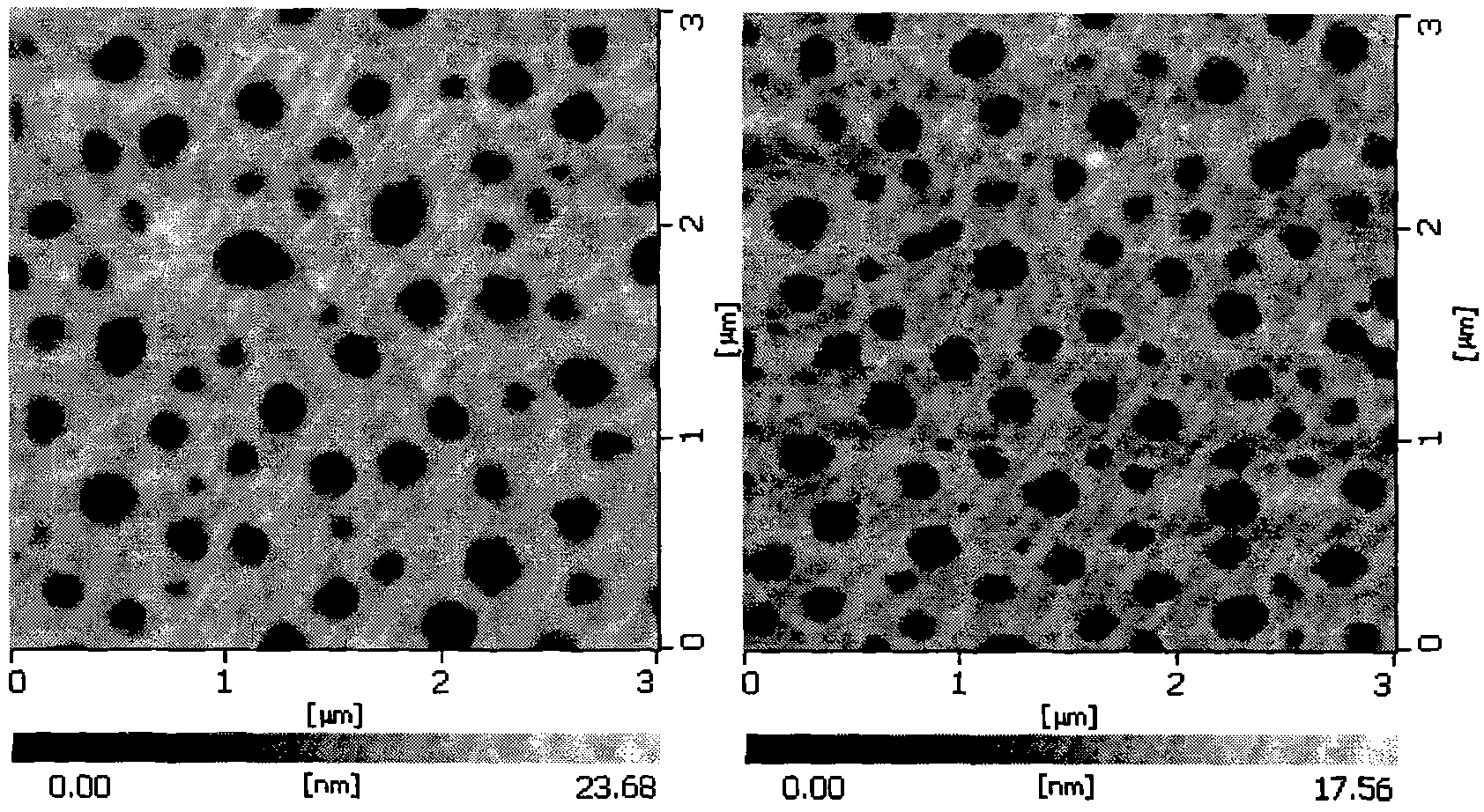

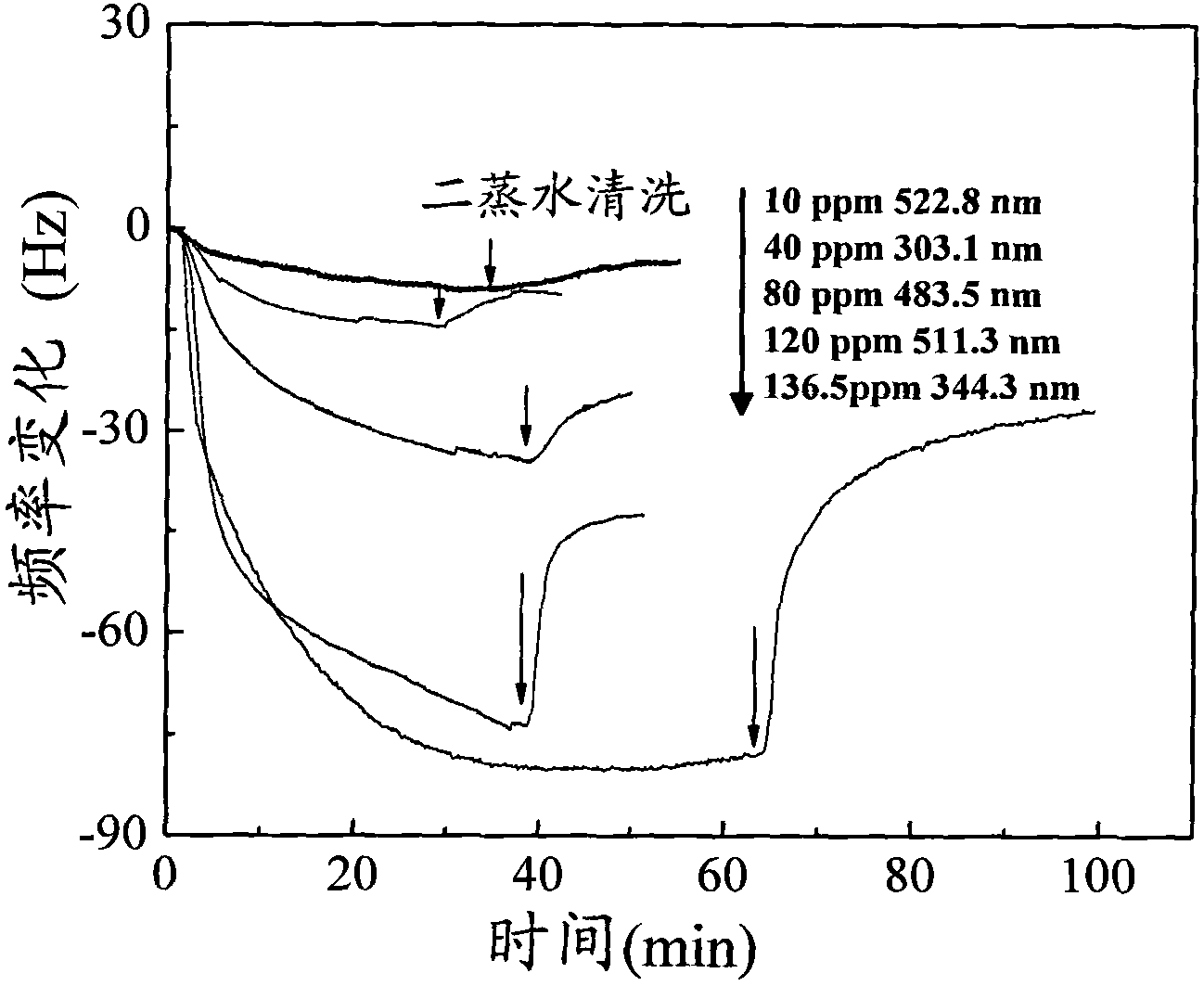

Method used

Image

Examples

Embodiment 1

[0049] Take 6.0777g of 2-mercaptobenzothiazole and add it to the polymerization bottle, dissolve it completely with 15ml of tetrahydrofuran, then add 1.5302g of sodium hydride into the bottle, a large number of bubbles will be formed during the reaction, and fully react for half a day at room temperature after the bubbles completely disappear. hours to form 2-mercaptobenzothiazole sodium salt. Take out the supernatant sodium salt clear solution in the reaction flask with a syringe, then add it to 10.2ml of tetrahydrofuran solution containing 5.20ml of p-chloromethylstyrene and continue to react at 50°C for 24h. The reaction solution was added dropwise to a large amount of 3‰ sodium hydroxide aqueous solution to precipitate, and a filter cake was formed by suction filtration, then washed with a 3‰ sodium hydroxide aqueous solution and separated, vacuum-dried to constant weight, and prepared In 2-mercaptobenzothiazole derivatives.

[0050] Dissolve 1ml of N-vinylimidazole monom...

Embodiment 2

[0055] Dissolve 0.5ml of N-vinylimidazole monomer and 1g of the 2-mercaptobenzothiazole derivative prepared in Example 1 in 15ml of dioxane, stir it under a nitrogen atmosphere to fully dissolve it, and then add 10mg of azobis Isobutyronitrile, fully stirred, reacted at a constant temperature in an oil bath of 80°C under nitrogen atmosphere for 24 hours, then took it out and cooled it to room temperature naturally. After the reaction is completed, it is a slightly turbid slightly yellow solution, which is centrifuged at 3500 rpm for 10 minutes to remove the suspended insoluble particles in the reaction solution; the upper layer of light yellow supernatant is precipitated in a large amount of acetone, and is also centrifuged at 3500 rpm for 10 minutes to obtain A light yellow precipitate was dried in a vacuum oven at 60° C. to a constant weight to obtain 0.85 g of a functional polymer: poly(2-mercaptobenzothiazole derivative-co-N-vinylimidazole) random copolymer. The weight-ave...

Embodiment 3

[0059] Dissolve 0.5ml of N-vinylimidazole monomer and 0.5073g of the 2-mercaptobenzothiazole derivative prepared in Example 1 in 10ml of dioxane, stir it under a nitrogen atmosphere to fully dissolve it, and then add 8mg of azo Diisobutyronitrile, fully stirred, reacted at a constant temperature in an oil bath at 80°C under nitrogen atmosphere for 24 hours, then took it out and cooled it to room temperature naturally. After the reaction was completed, it was a slightly turbid slightly yellow solution, which was centrifuged at 3500 rpm for 10 minutes to remove suspended insoluble particles in the reaction solution; the light yellow supernatant liquid in the upper layer was precipitated in a large amount of acetone, and centrifuged at 3500 rpm for 10 minutes to obtain a light yellow precipitate. The precipitate was dried in a vacuum oven at 60° C. to a constant weight to obtain 0.75 g of a functional polymer: poly(2-mercaptobenzothiazole derivative-co-N-vinylimidazole) random cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com