Bobbin case replacement device

A bobbin case and material storage technology, applied to auxiliary devices, embroidery machine mechanisms, embroidery machines, etc., can solve the problems of reducing embroidery machine output, increasing equipment manufacturing and maintenance costs, and manual recycling, so as to improve work efficiency and continuous Work stability, prolong continuous working time, and facilitate installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

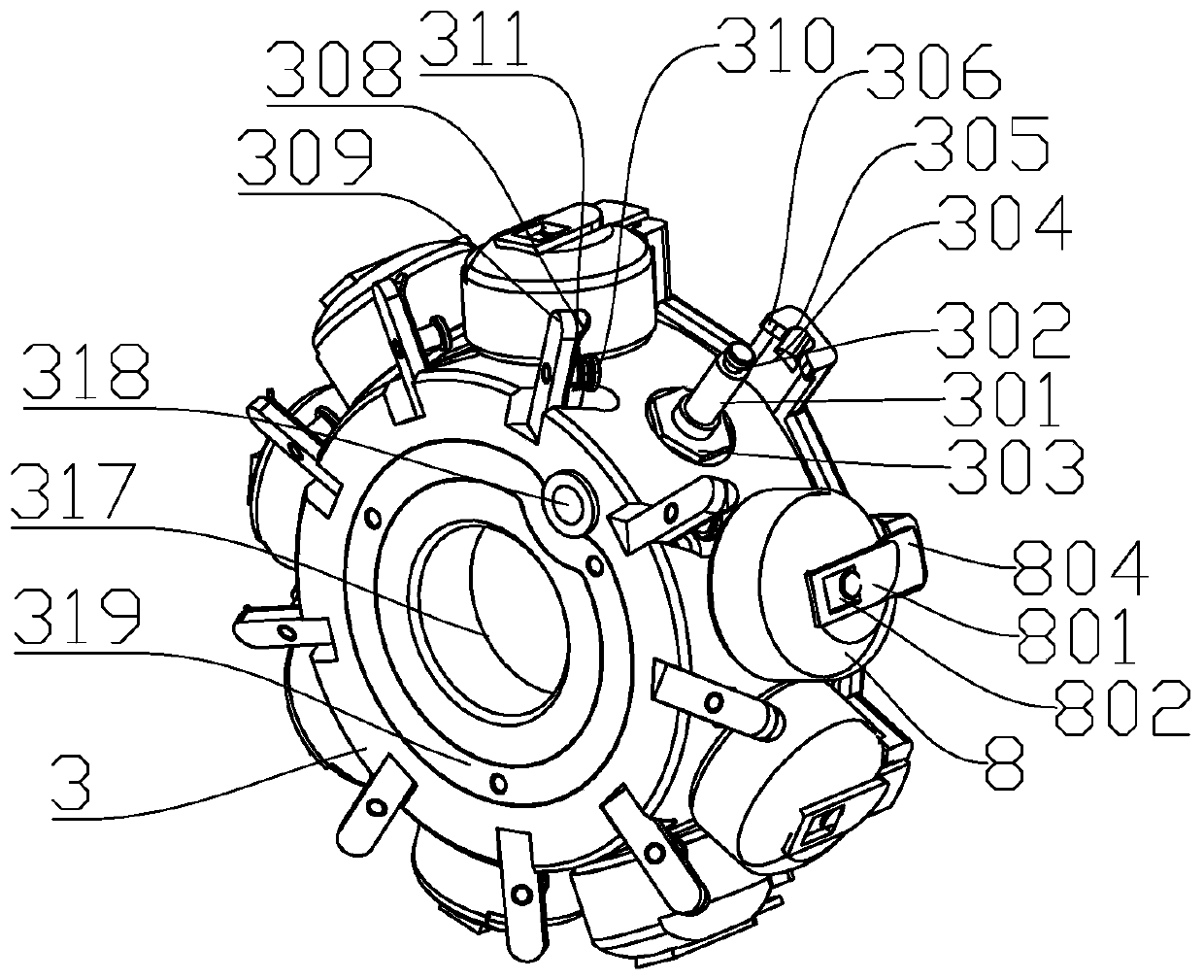

[0041] Such as figure 1 As shown, the embodiment of the present invention provides a bobbin case 8 replacement device, which includes a bobbin case 8 grasping part 4 and a bobbin case storage part, the bobbin case storage part is arranged under the bobbin case 8 grasping part 4, and the shuttle The shell storage part is provided with one or more bobbin case storage devices; the bobbin case storage device includes a storage turntable 3, and a number of bobbin case 8 storage stations are arranged around the storage turntable 3, and the bobbin case 8 storage stations Including a mandrel 301 for placing the bobbin case 8; the mandrel 301 is fixedly connected to the side of the storage carousel 3 along the radial direction of the storage carousel 3; the two sides of the mandrel 301 are respectively equipped with bobbin case 8 positioning pieces 304 and thread clamping structure.

[0042] The top of the mandrel 301 is provided with an annular positioning groove 302 for positioning ...

Embodiment 2

[0053] Such as image 3 , Figure 4 , Figure 5 As shown, the embodiment of the present invention has made the following improvements on the basis of embodiment 1:

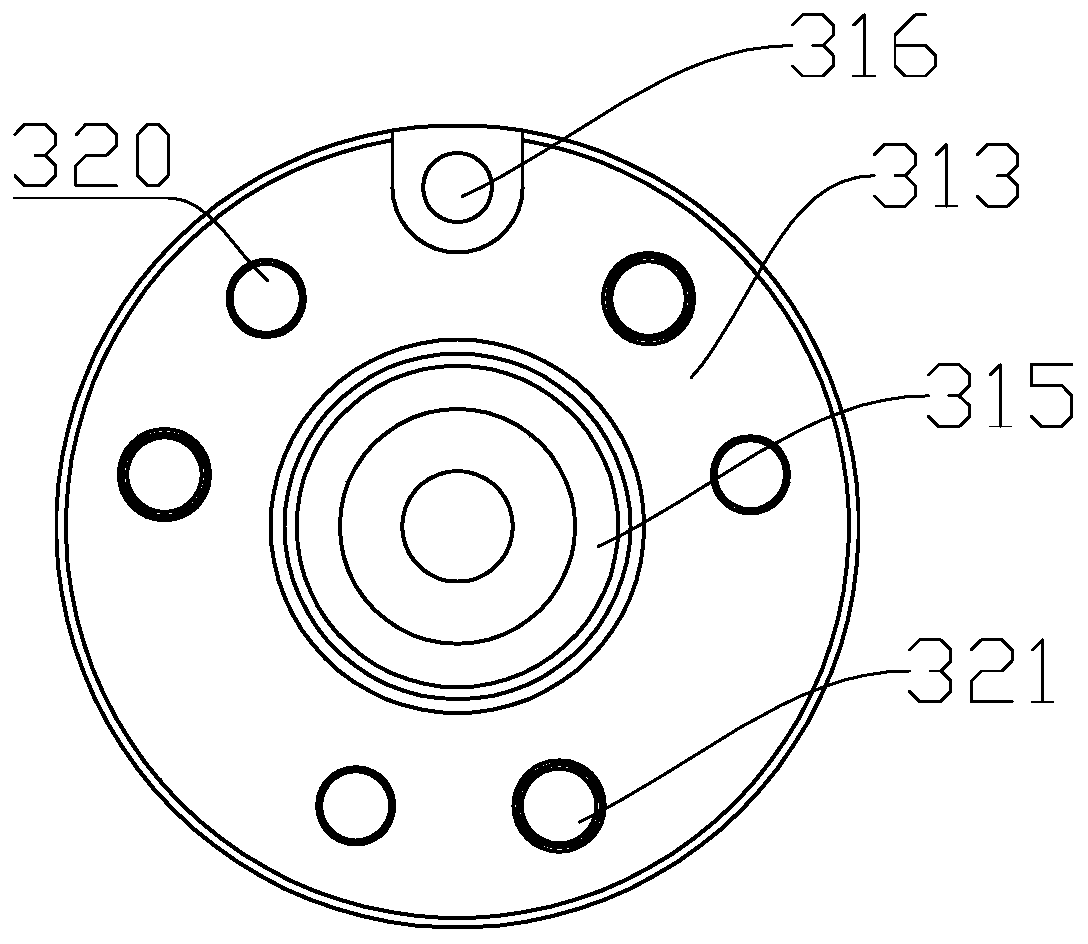

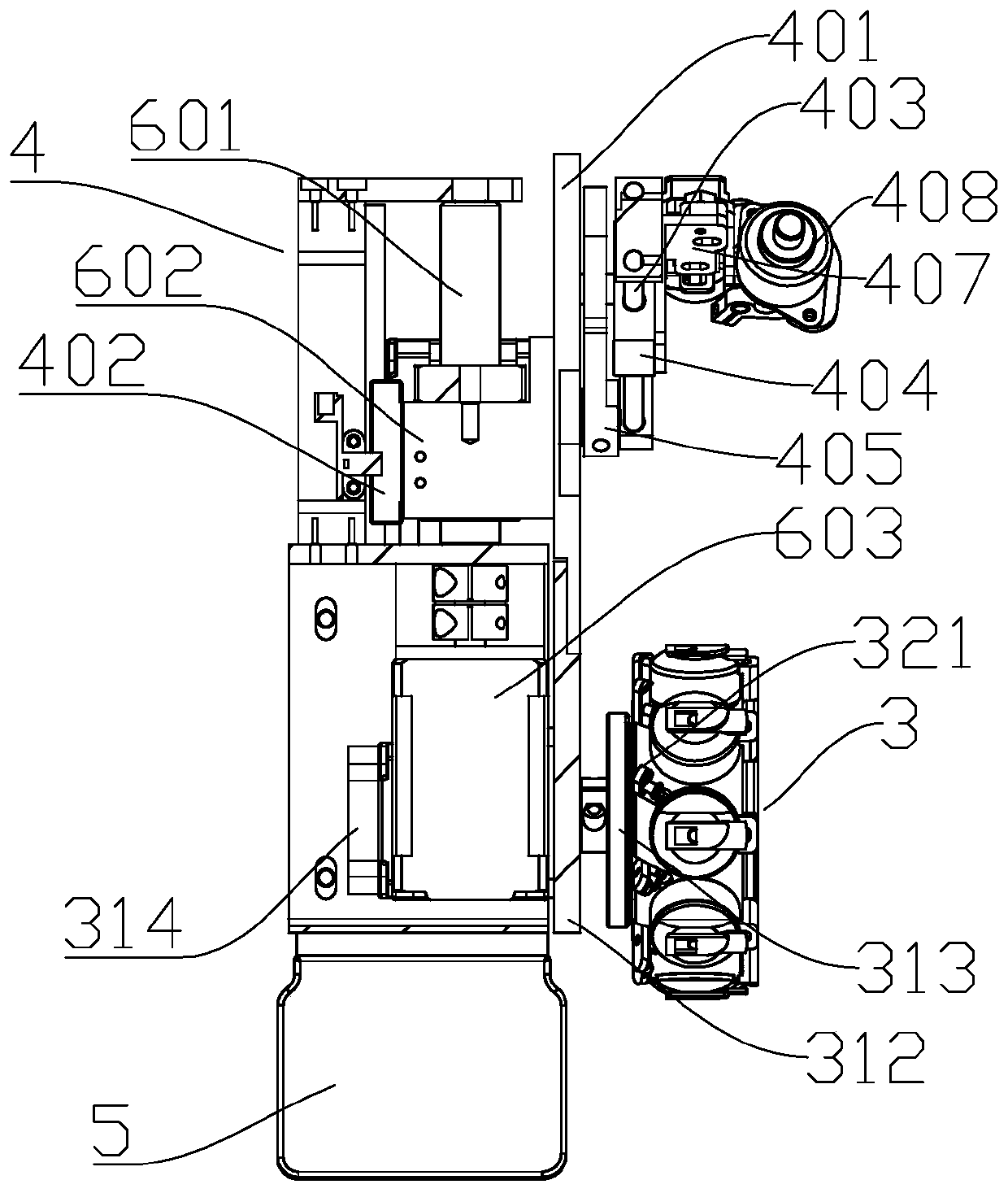

[0054] The bobbin case storage part also includes a first base plate 312 and a first servo motor 314, the first servo motor 314 is arranged on one side of the first base plate 312, and the output shaft of the first servo motor 314 passes through the first base plate 312 Connect the driving disc 313 of the bobbin case storage device.

[0055] The grasping part 4 of the bobbin case 8 includes a second base plate 401, a swing telescopic mechanism and a mechanical finger mechanism. The swing telescopic mechanism is rotatably connected to the second substrate 401. , the mechanical finger mechanism points to the bobbin case 8 storage station on the storage carousel 3, and the first base plate 312 and the second base plate 401 are fixedly connected.

[0056] The swing telescopic mechanism includes a second servo moto...

Embodiment 3

[0063] combine Figure 9 As shown, the embodiment of the present invention has made the following improvements on the basis of Embodiment 2: the bobbin case storage part is provided with a plurality of bobbin case storage devices, and each bobbin case storage device is coaxially fixedly connected to the first On the output shaft of the servo motor 314; offset or keep the same distance between two adjacent bobbin housing storage devices, and the positioning pins 316 on each drive disc 313 are located on the same straight line.

[0064] Further, when the storage stations of the bobbin case 8 are equiangularly arranged on the outside of the storage carousel 3, the central angles corresponding to the two adjacent mandrels 301 are a, and the positions of any two bobbin case storage devices are The central angle formed by the positioning pin 316 on a plane parallel to the driving disk 313 and the axis of the driving shaft 315 is an integer multiple of a.

[0065] The bobbin case re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com