Jacking unit for beam falling of railway precast beam

A lifting unit and railway technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low adjustment efficiency and achieve the effect of stable structure, high adjustment efficiency and small overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

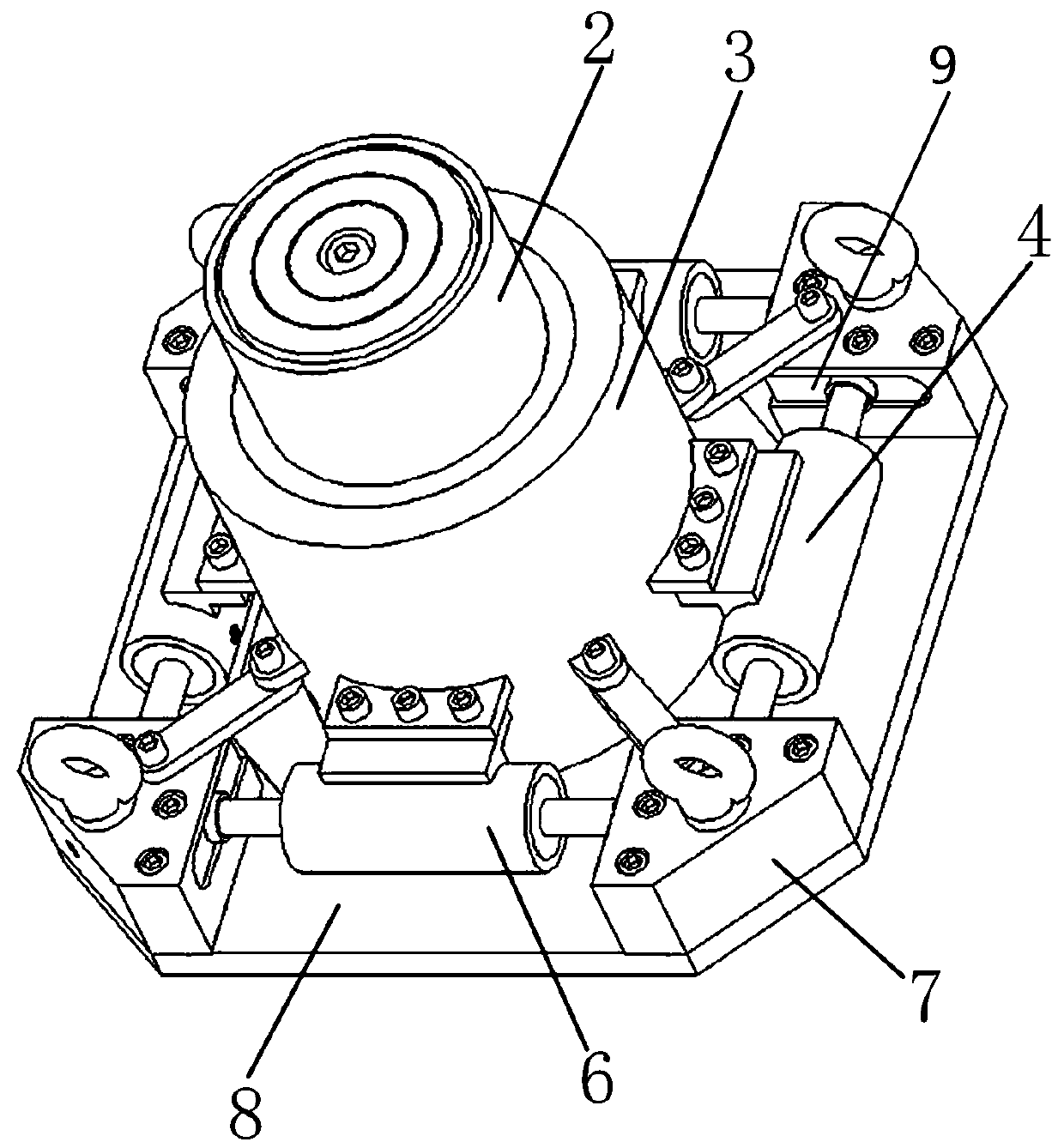

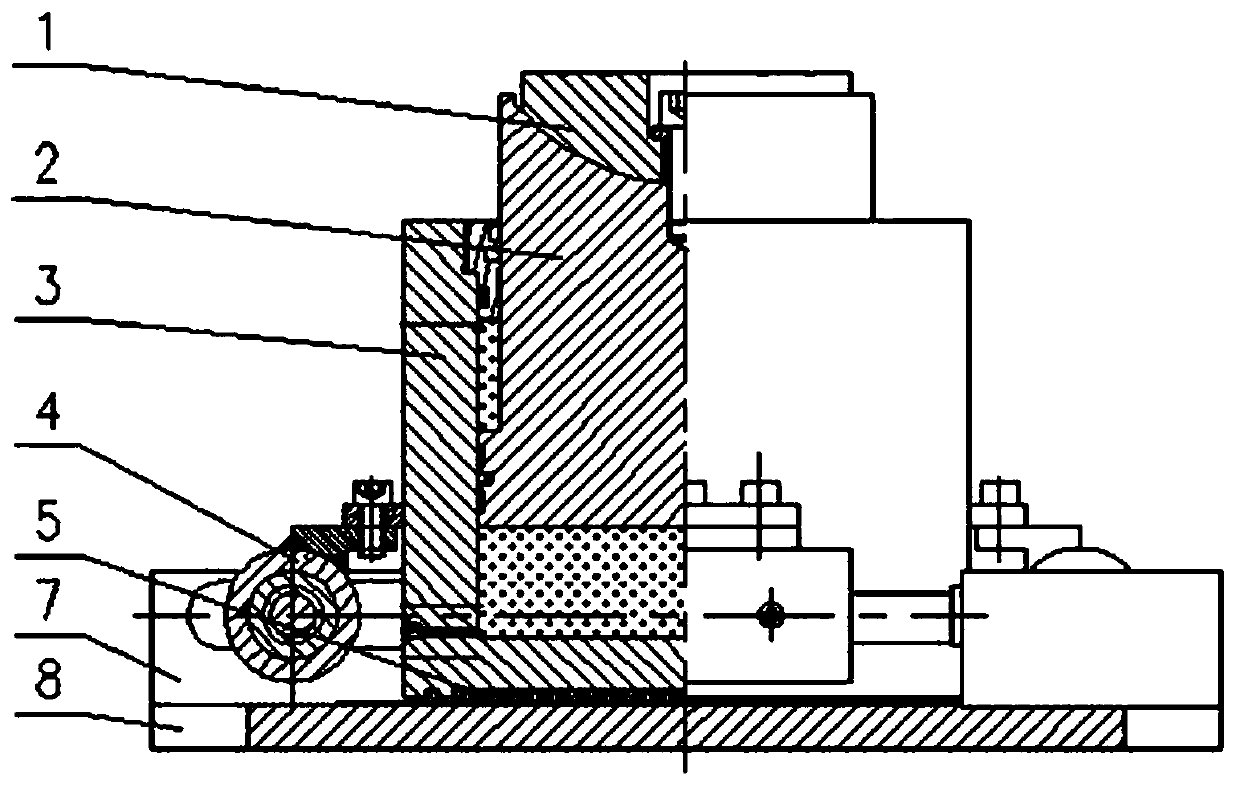

[0015] as attached figure 1 , 2 As shown, the present invention includes a bottom plate 8, a horizontal adjustment device arranged on the bottom board 8 for adjusting the horizontal position, and a vertical adjustment device arranged on the horizontal adjustment device, and the vertical adjustment device is in contact with the supported member.

[0016] The horizontal adjustment device includes a reaction force block 7 fixedly arranged on the bottom plate 8 and a horizontal adjustment module and a longitudinal adjustment module arranged on the reaction force block 7. The horizontal adjustment module is the first two-way hydraulic cylinder 6, and the longitudinal adjustment module is the second Two two-way hydraulic cylinders 4, the vertical adjustment device is a vertical lifting jack 3.

[0017] The cylinder bodies of the first two-way hydraulic cylinder 6 and the second two-way hydraulic cylinder 4 are fixedly connected with the vertical adjustment device, and the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com