Combined sealing device for energy absorption and explosion discharge of coal spontaneous combustion fire zone and construction technology of combined sealing device

A construction technology, coal spontaneous combustion technology, applied in mining installations, mining equipment, earthwork drilling, etc., to achieve the effects of high impact resistance, short construction time and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

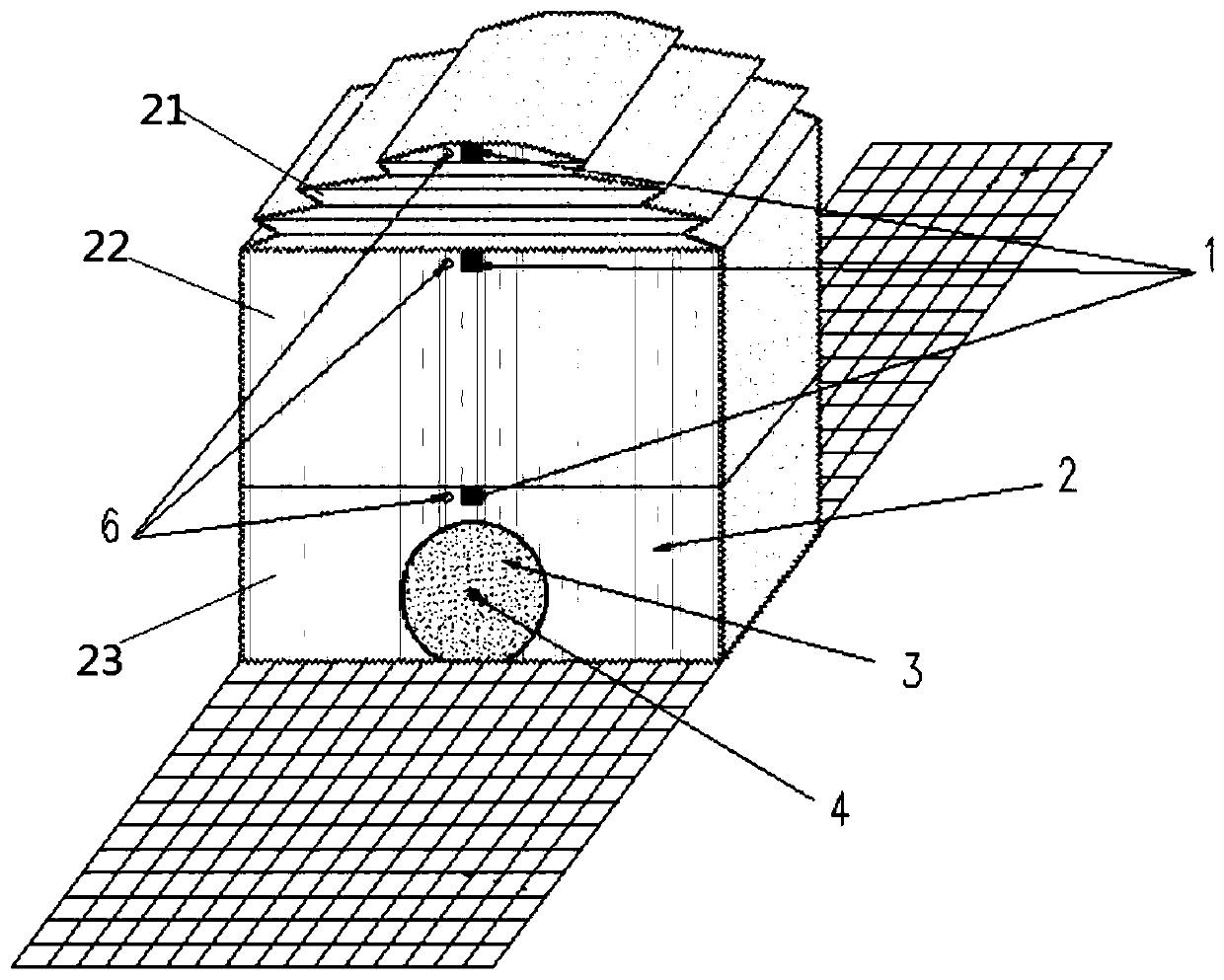

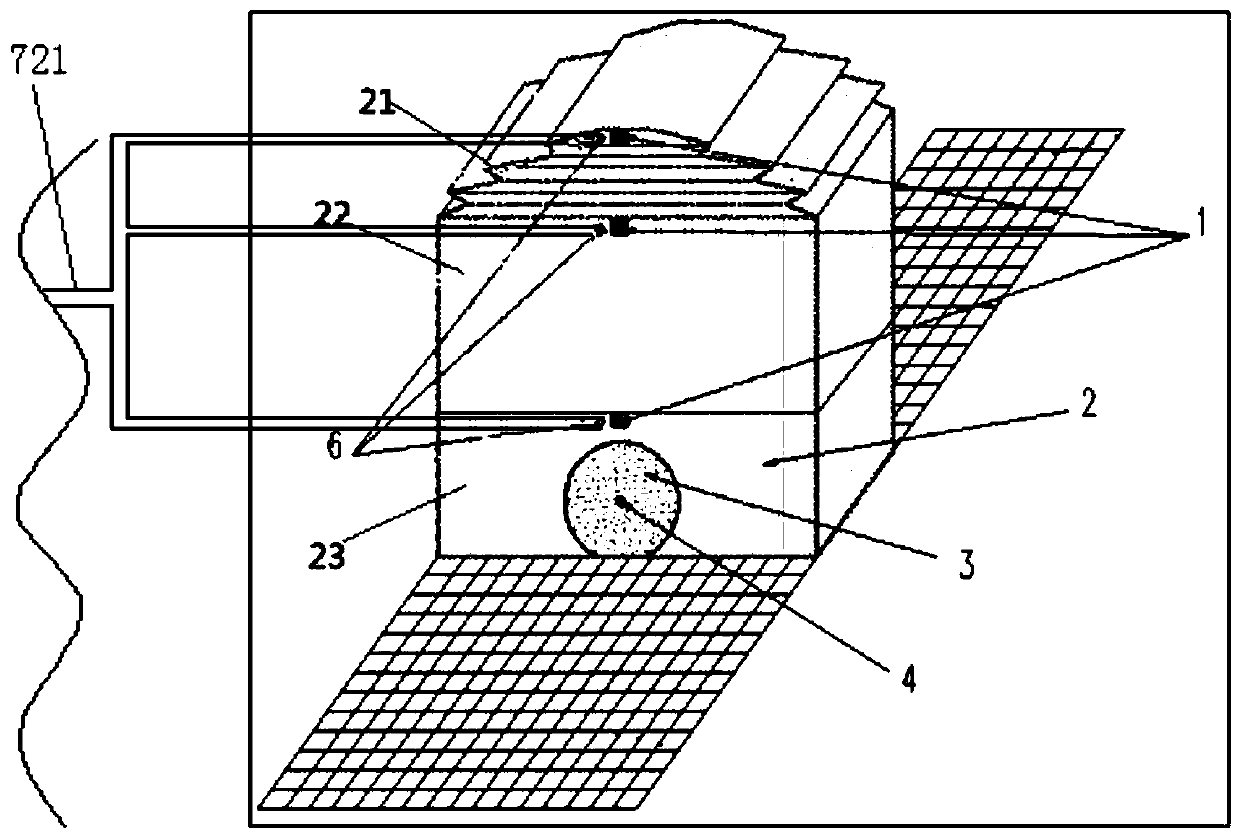

[0034] A combined airtight device for energy absorption and explosion relief in coal spontaneous combustion fire zone, specifically as Figure 1-3 As shown, colloidal explosion-proof bag 2 and airbag bag 3 are made of a blend of metallocene polyethylene and general-purpose polyethylene in a mass ratio of 30:70;

[0035] The colloidal explosion-proof bag 2 is a hollow soft structure with an arched top. The thickness of the colloidal explosion-proof bag 2 is 1m. The mass ratio is the first interlayer and the second interlayer made of the blend of 30:70, and the first interlayer and the second interlayer separate the inside of the colloidal explosion-proof bag 2 from top to bottom into an arched cavity 21, The first cavity 22 and the second cavity 23;

[0036] There are grouting holes 6 on the top of the same side of the arched cavity 21, the first cavity 22 and the second cavity 23. The grouting holes 6 are connected with a grouting pipe, and the grouting pipe is connected with...

Embodiment 2

[0052] A combined airtight device for energy absorption and explosion relief in coal spontaneous combustion fire zone, specifically as Figure 1-2 As shown, colloidal explosion-proof bag 2 and airbag bag 3 are made of a blend of metallocene polyethylene and general-purpose polyethylene in a mass ratio of 40:60;

[0053] The colloidal explosion-proof bag 2 is a hollow soft structure with an arched top. The thickness of the colloidal explosion-proof bag 2 is 3m. The mass ratio is the first interlayer and the second interlayer made of the blend of 40:60, and the first interlayer and the second interlayer separate the inside of the colloid explosion-proof bag 2 from top to bottom into an arched cavity 21, the second interlayer A cavity 22 and a second cavity 23;

[0054] There are grouting holes 6 on the top of the same side of the arched cavity 21, the first cavity 22 and the second cavity 23. The grouting holes 6 are connected with a grouting pipe, and the grouting pipe is conn...

Embodiment 3

[0069] A combined airtight device for energy absorption and explosion relief in coal spontaneous combustion fire zone, specifically as Figure 1-2 As shown, colloidal explosion-proof bag 2 and airbag bag 3 are made of a blend of metallocene polyethylene and general-purpose polyethylene in a mass ratio of 50:50;

[0070] The colloidal explosion-proof bag 2 is a hollow soft structure with an arched top. The thickness of the colloidal explosion-proof bag 2 is 5m. The mass ratio is the first interlayer and the second interlayer made of the blend of 50:50, and the first interlayer and the second interlayer separate the inside of the colloid explosion-proof bag 2 from top to bottom into an arched cavity 21, the second interlayer A cavity 22 and a second cavity 23;

[0071]There are grouting holes 6 on the top of the same side of the arch cavity 21, the first cavity 22 and the second cavity 23, and the grouting holes 6 are connected with grouting pipes; the grouting pipes are connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com