Ultra-high pressure chilled food instant freezing device for food quick freezing process

An ultra-high pressure and food technology, which is applied in household refrigeration devices, cooling fluid circulation devices, coolers, etc., can solve problems such as food that is prone to freezing and cracking, and achieve the effect of solving high energy consumption and maintaining quality and original state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

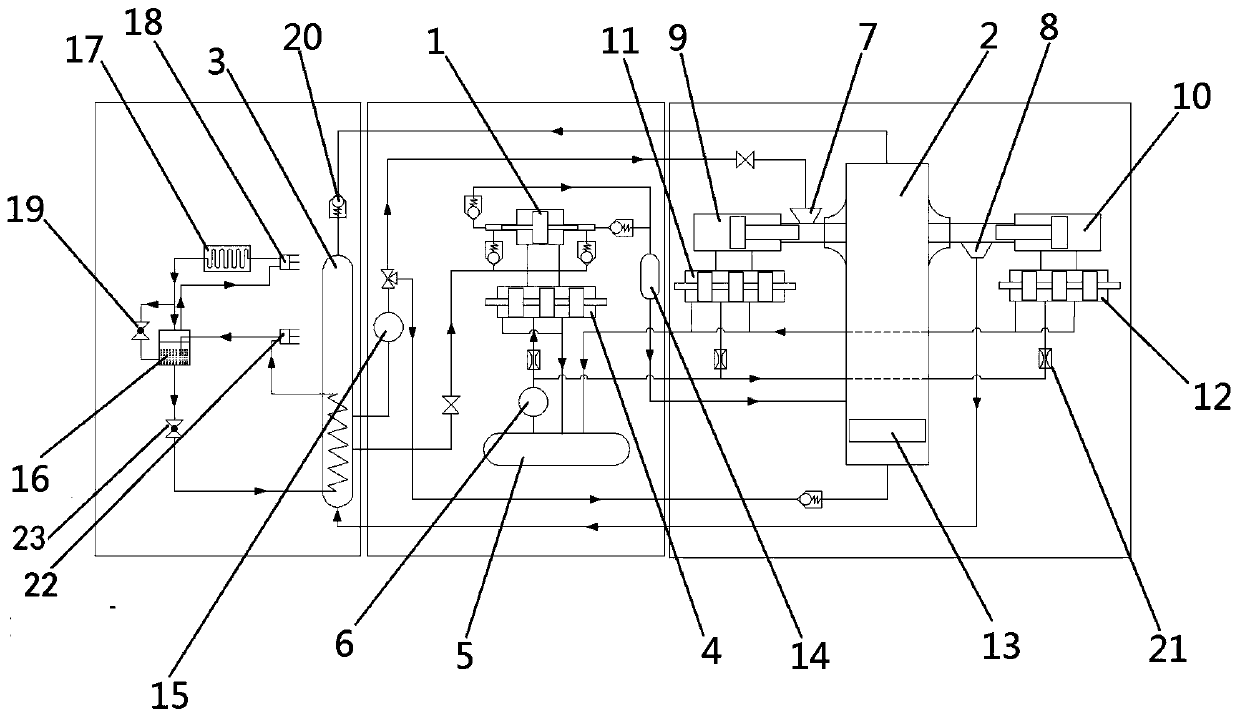

[0030] see figure 1 A kind of ultra-high pressure cooling food instant freezing device for food quick-freezing processing provided in this embodiment includes:

[0031] Ethanol liquid storage tank 3, pressurized cylinder 1, refrigeration unit, ultra-high pressure reactor 2 and pipelines;

[0032] The refrigerating unit includes a low-stage compressor 22, an intercooler 16, a high-stage compressor 18, a condenser 17, a first throttle valve 19, a second throttle valve 23, and an evaporation coil built into the ethanol liquid storage tank 3; The pipe is connected with the low-stage compressor 22, the intercooler 16, the high-stage compressor 18, the condenser 17, the first throttle valve 19, and the second throttle valve 23 through pipelines;

[0033] The booster cylinder 1 is connected with the first three-position four-way electromagnetic reversing valve 4, and the first three-position four-way electromagnetic reversing valve 4 is connected with the first hydraulic pump 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com