Preparation method of WO3/MoO3 composite electrochromic film

An electrochromic film and thin film technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as constraints, and achieve the effects of low cost, good electrochromic performance, and simple and easy-to-operate preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

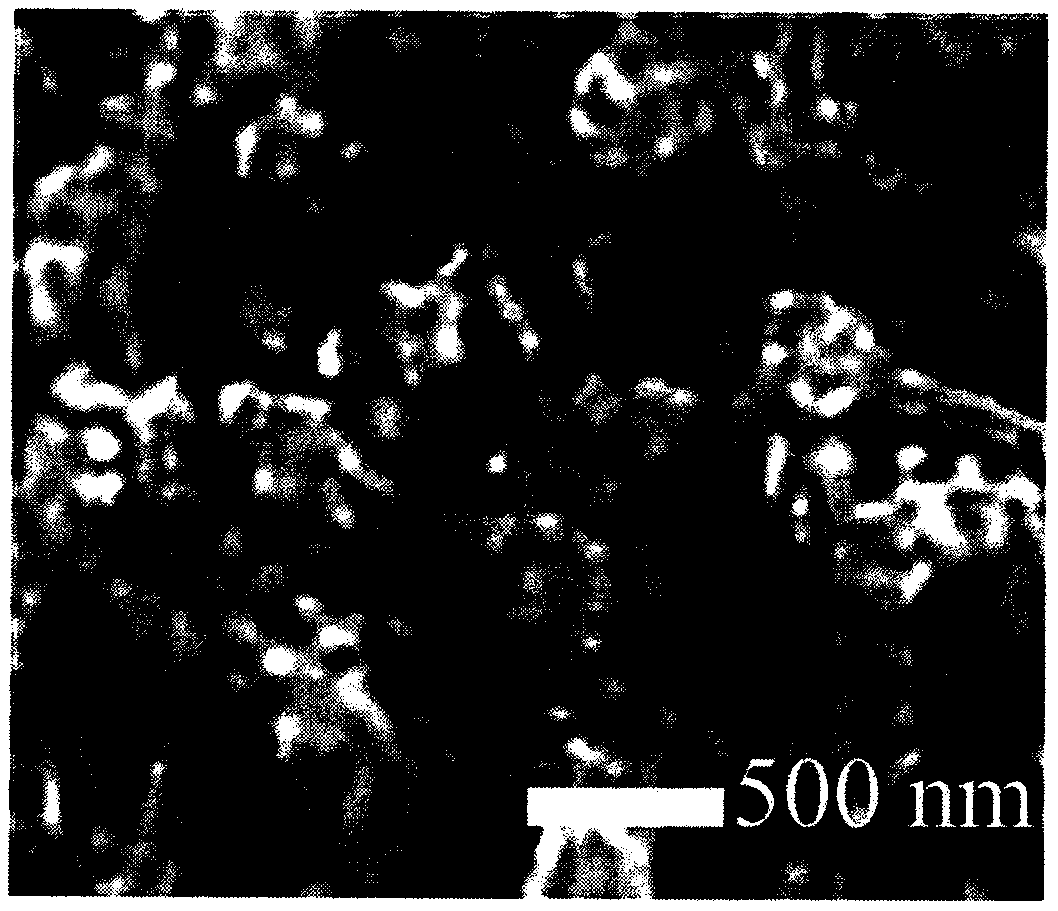

Image

Examples

Embodiment 1

[0023] Step 1: Preparation of WO 3 nanorod array film

[0024] Take Na 2 WO 4 2H 2 O is the precursor, deionized water is the solvent, and a 0.03mol L -1 reaction solution, add 0.01mol·L -1 K 2 C 2 o 4 ·H 2 O is the structure-directing agent, then, add HCl dropwise to adjust the pH value of the solution to 1.4, place the clean conductive glass in the above reaction solution, and conduct a hydrothermal reaction at 175°C for 28 hours. After the reaction, wash the sample with deionized water, Drying, and finally annealing at 530°C, to obtain WO 3 Nanorod Array Films.

[0025] Step 2: Preparation of WO 3 / MoO 3 Composite electrochromic film

[0026] Take Na 2 MO 4 as the precursor, deionized water as the solvent, stirred at 25°C for 3 hours, and prepared 0.02mol L -1 MoO 3 Electrodeposition solution, with WO 3 The nanorod array film is the working electrode, Pt is the counter electrode, and the MoO 3 In the electrodeposition solution, the reaction temperature is...

Embodiment 2

[0028] Step 1: Preparation of WO 3 nanorod array film

[0029] Take Na 2 WO 4 2H 2 O is the precursor, deionized water is the solvent, and a 0.05mol L -1 reaction solution, add 0.03mol·L -1 K 2 C 2 o 4 ·H 2 O is the structure-directing agent, then, add HCl dropwise to adjust the pH value of the solution to 1.6, place the clean conductive glass in the above reaction solution, and conduct a hydrothermal reaction at 185°C for 20 hours. After the reaction, wash the sample with deionized water, Drying, and finally annealing at 570°C, to obtain WO 3 Nanorod Array Films.

[0030] Step 2: Preparation of WO 3 / MoO 3 Composite electrochromic film

[0031] Take Na 2 MO 4 as the precursor, deionized water as the solvent, stirred at 30°C for 3 hours, and prepared 0.04mol L -1 MoO 3 Electrodeposition solution, with WO 3 The nanorod array film is the working electrode, Pt is the counter electrode, and the MoO 3 In the electrodeposition solution, the reaction temperature wa...

Embodiment 3

[0033] Step 1: Preparation of WO 3 nanorod array film

[0034] Take Na 2 WO 4 2H 2 O is the precursor, deionized water is the solvent, and a 0.04mol L -1 reaction solution, add 0.02mol·L -1 K 2 C 2 o 4 ·H 2 O is the structure-directing agent, then, add HCl dropwise to adjust the pH value of the solution to 1.5, place the clean conductive glass in the above reaction solution, and conduct a hydrothermal reaction at 180°C for 24 hours. After the reaction, wash the sample with deionized water, Drying, and finally annealing at 550°C, to obtain WO 3 Nanorod Array Films.

[0035] Step 2: Preparation of WO 3 / MoO 3 Composite electrochromic film

[0036] Take Na 2 MO 4 as the precursor, deionized water as the solvent, stirred at 28°C for 3 hours, and prepared 0.03mol L -1 MoO 3 Electrodeposition solution, with WO 3 The nanorod array film is the working electrode, Pt is the counter electrode, and the MoO 3 In the electrodeposition solution, the reaction temperature is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com