al with mosaic structure 2 o 3 /wo 3 Nanocomposite electrochromic film and preparation method thereof

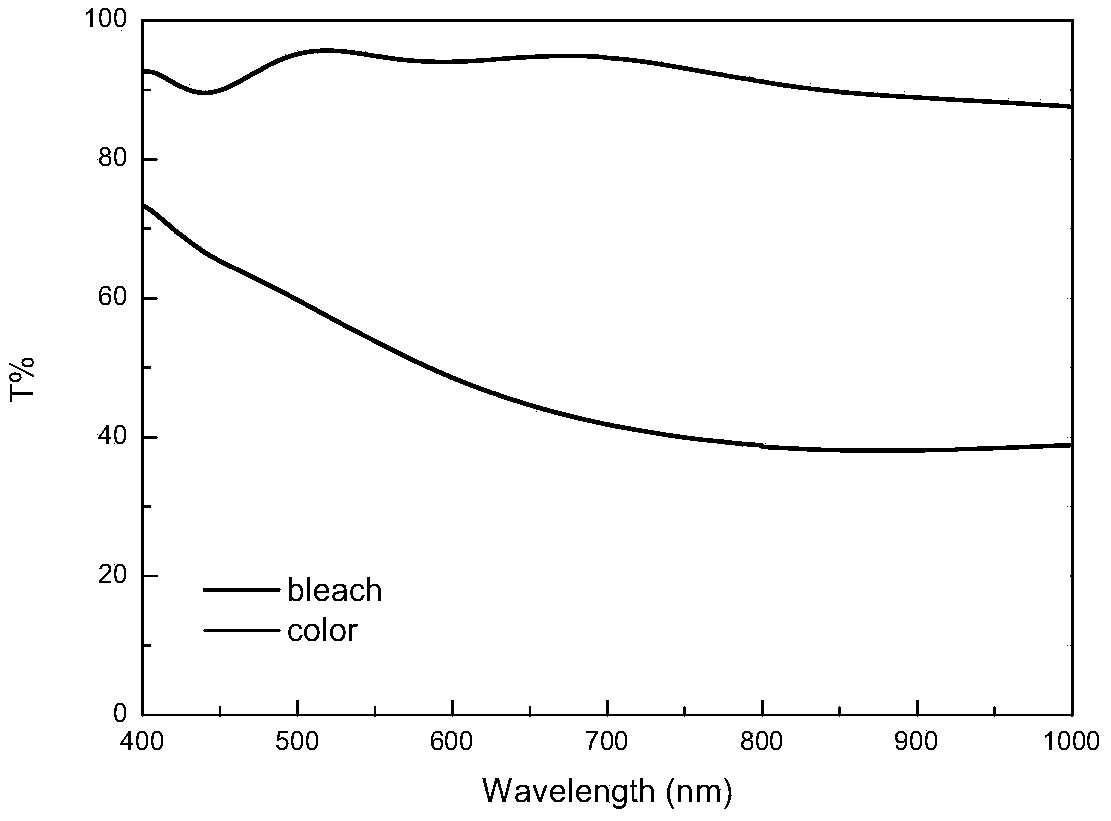

A nano-composite and electrochromic technology, applied in coatings and other directions, can solve the problems of long response time, low spectral modulation amplitude, low discoloration efficiency, etc., and achieve the effects of improving discoloration efficiency, improving chemical activity, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0026] In this implementation case, ITO glass (30mm×30mm) is used as the substrate, and the following cleaning steps are performed before coating: ultrasonically clean the ITO glass in acetone for 30 minutes → rinse with deionized water for 3 times, then put it into deionized water for 30 minutes with ultrasonication → deionize After rinsing in water for 3 times, perform ultrasonication in ethanol for 30 minutes → dry and set aside.

[0027] Step (1): ultrasonically disperse 1.6g of Al2O3 nanoparticle powder in 5mL of water to form Al 2 o 3 Aqueous solution of nanoparticles;

[0028] Step (2): Add 3g of ammonium metatungstate to the aforementioned Al 2 o 3 In the nanoparticle aqueous solution, the composite solution is obtained by ultrasonic treatment;

[0029] Step (3): Add 2.5mL of ethanol and 1.18ml of PEG400 successively to the compound solution mentioned above, and perform ultrasonic treatment;

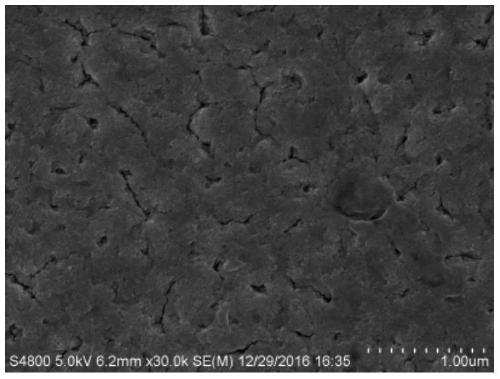

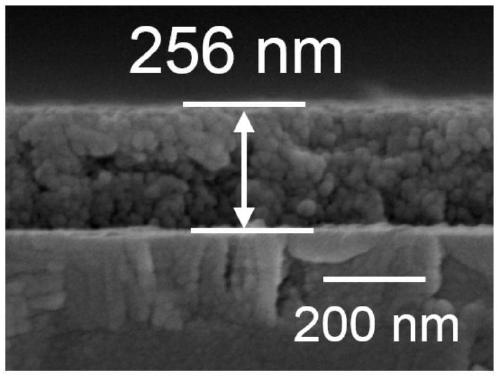

[0030]Step (4): Spin-coat the composite solution on the cleaned ITO sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com