Rubber wall bushing processing mold

A technology for penetrating the wall casing and processing molds, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of rubber entering screw holes, oil leakage and air leakage, small insulation margin, etc., and achieves accelerated rubber cooling, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

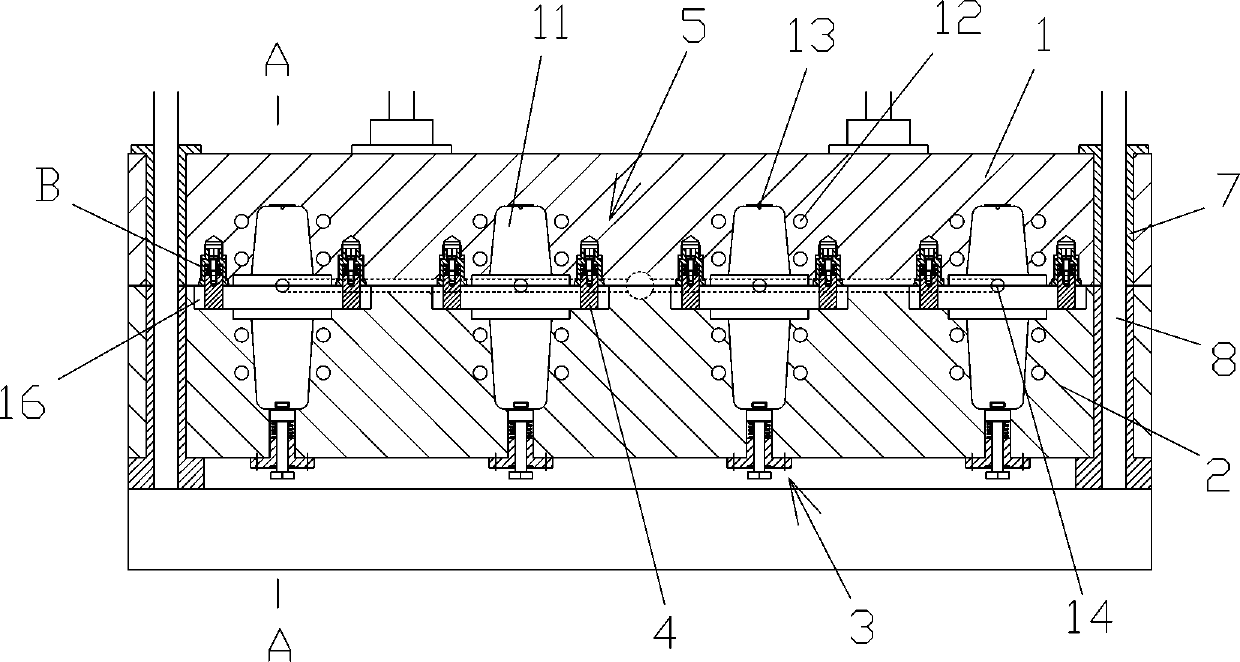

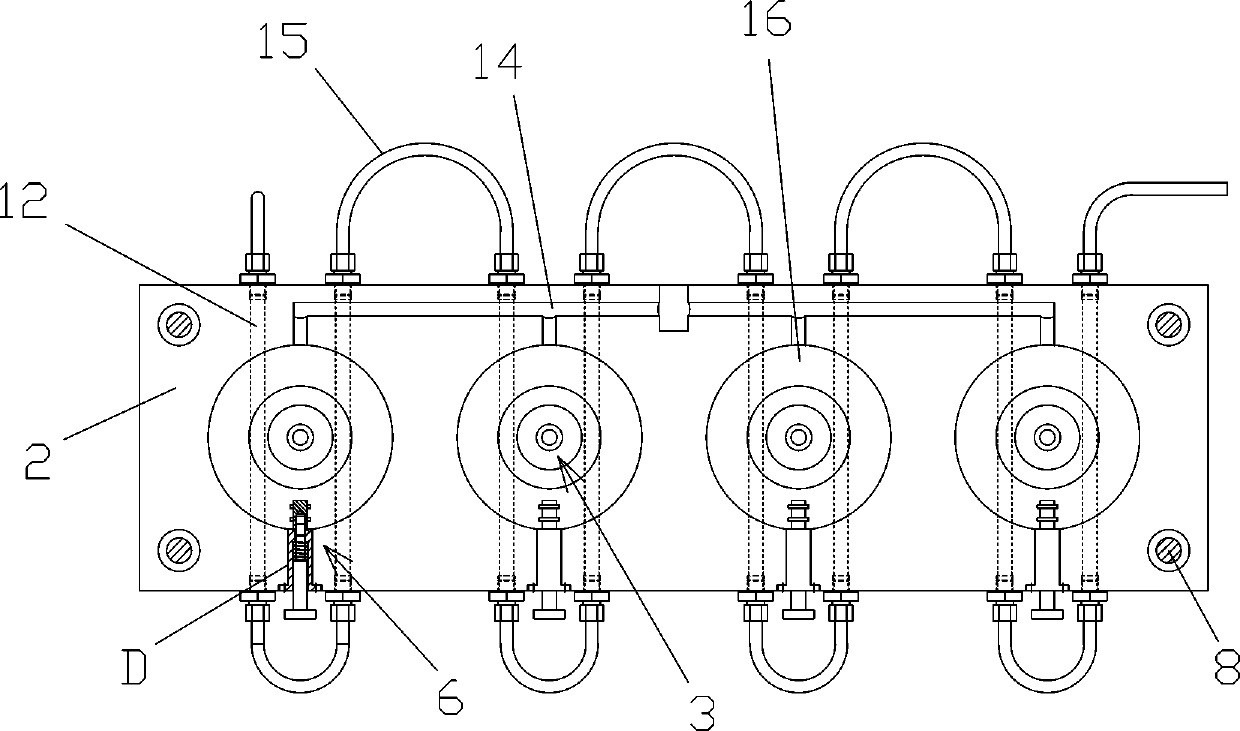

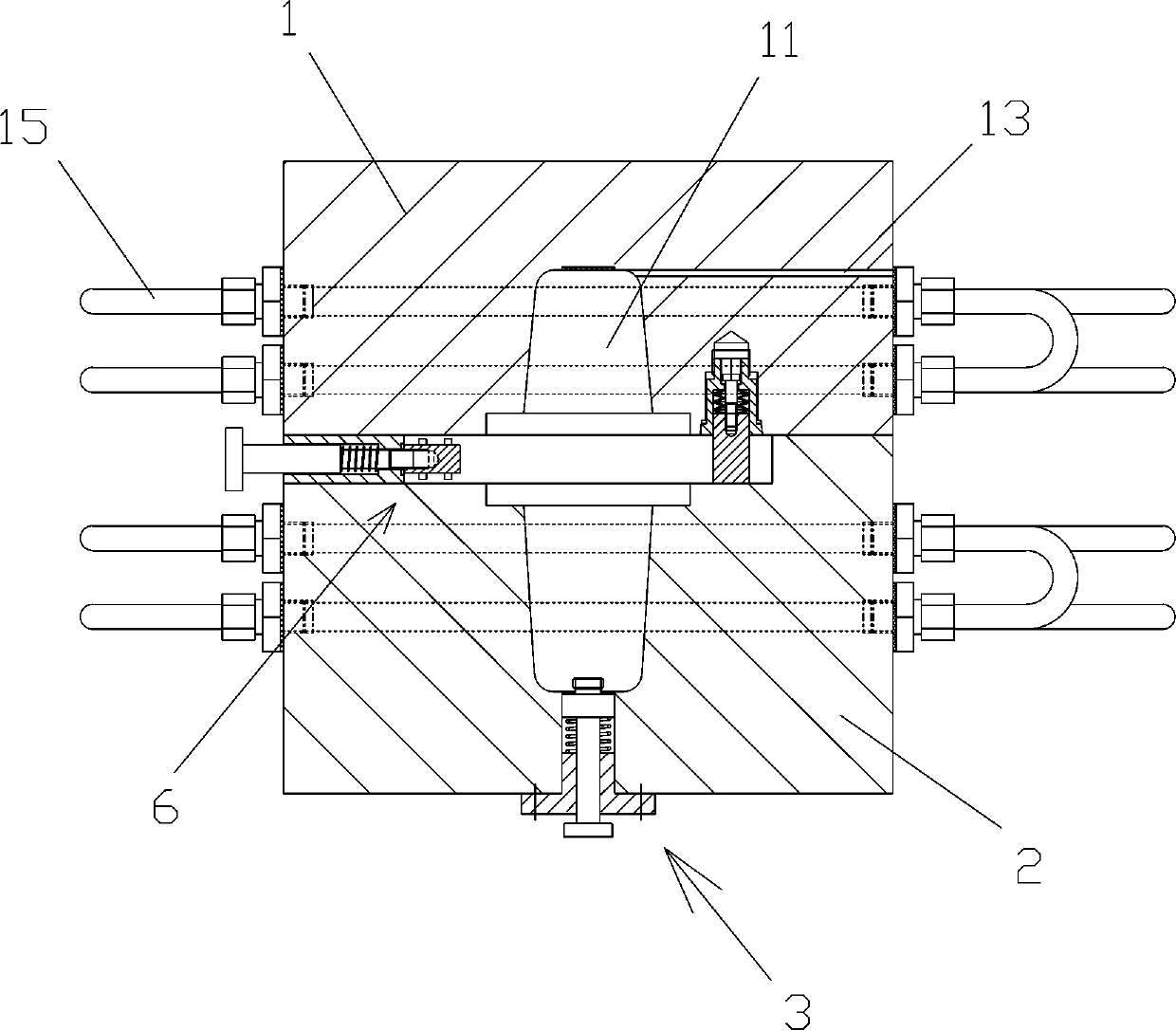

[0030] Such as figure 1 , 2 As shown in , 8, 9, 10 and 11, a rubber wall casing processing mold includes an upper mold 1, a lower mold 2, an oil cylinder 10, a guide sleeve 7 and a guide rod 8, and the oil cylinder 10 drives the upper mold 1 along the guide The rod 8 moves up and down, the upper mold 1 and the lower mold 2 are provided with a plurality of spindle-shaped chambers 11, the upper end of the chamber 11 of the lower mold 2 is provided with a flange groove 16, and a glue filling hole 14 is provided in the mold. A positioning mechanism 3 is installed at the bottom of each cavity 11 of the mold 2, and a plurality of flange pins 4 are installed around each cavity 11 of the upper mold 1, and each flange pin 4 is evenly distributed around the axis of the cavity 11 of the upper mold 1 The positioning mechanism 3 includes a through hole provided on the mould, a sliding sleeve 31 is installed in the through hole, a sliding rod 38 is provided in the sliding sleeve 31, and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com