Novel efficient eight-head digital ink-jet printer

A digital inkjet and printer technology, applied in typewriters, printing devices, printing and other directions, can solve the problems of affecting the development of printing work, easy collision and damage of the nozzle, and low printing efficiency, and achieves increased anti-collision function, improved service life, Use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

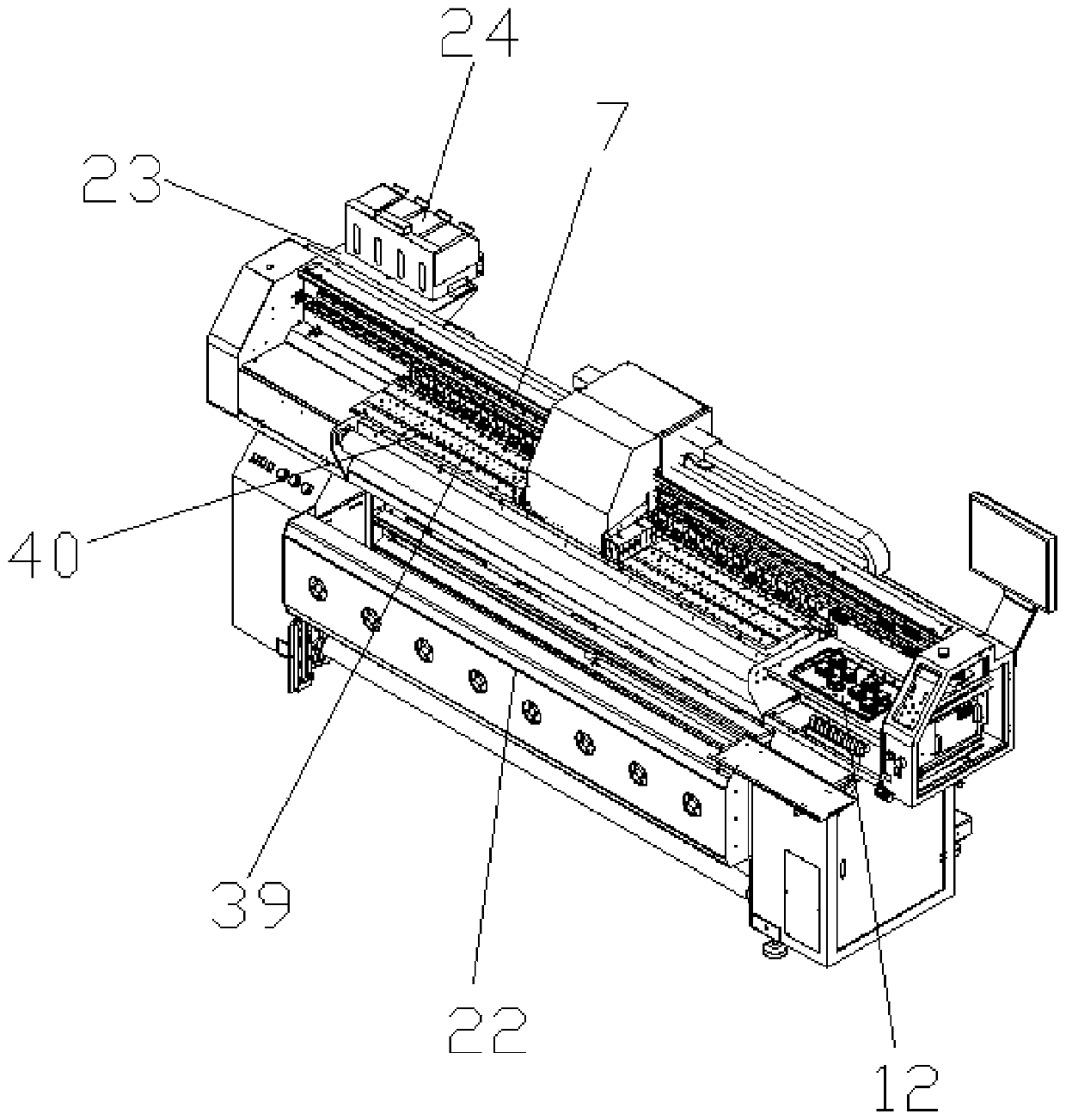

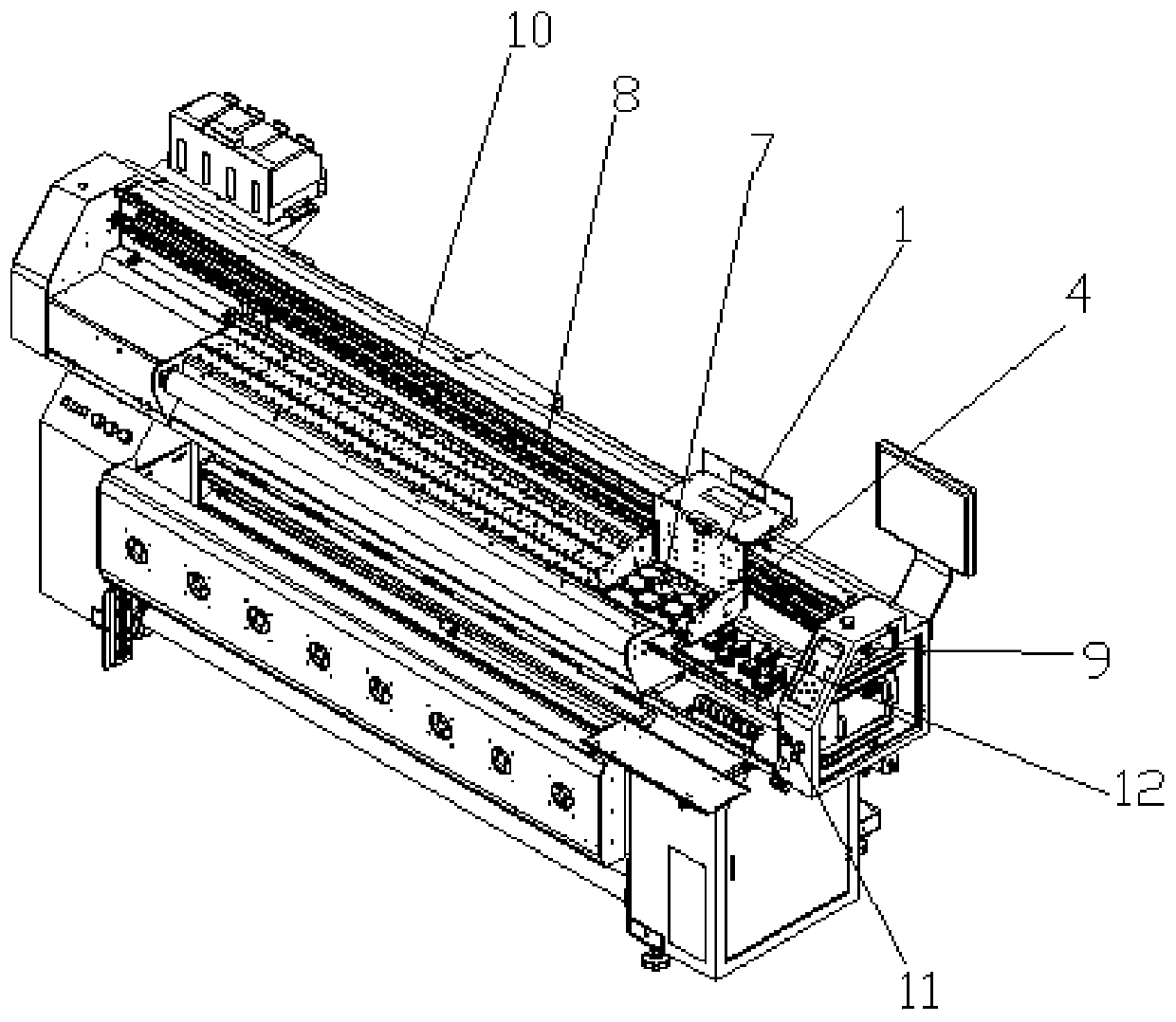

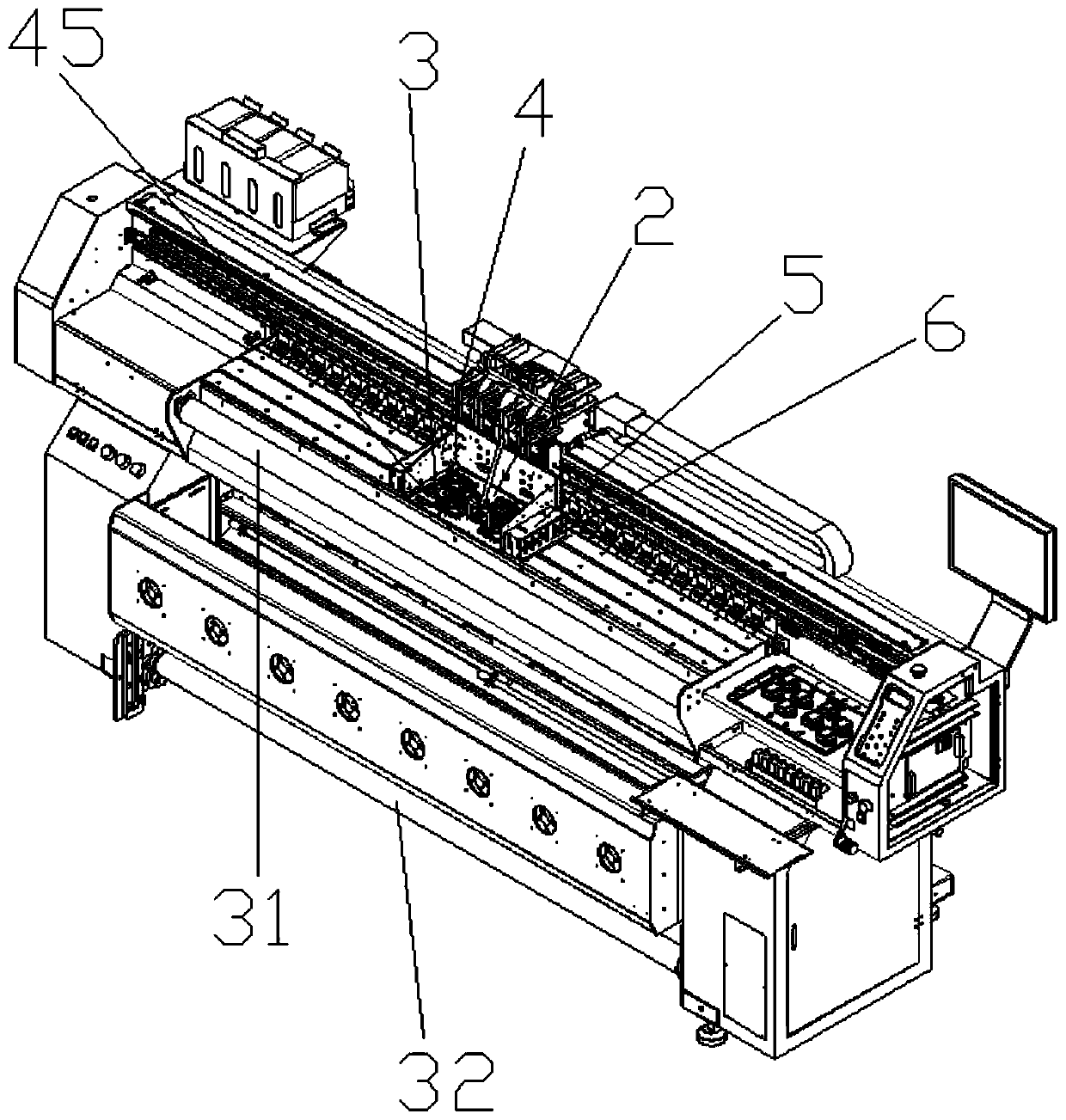

[0051] refer to Figure 1 to Figure 14 The new high-efficiency eight-head digital inkjet printer shown includes a printer main body, which is equipped with a printing device, a transmission device, a nozzle cleaning device, an air-drying device, a feeding device, a feeding device, a printing platform 39, and a display screen 38 And the internal control system, the transmission device includes a guide rail 8, a pulley 9 and a beam 10, the guide rail 8 is fixed on the beam 10, the pulley 9 is two, the pulley 9 is installed at both ends of the beam 10, and the pulley 9 is provided with a conveyor belt (not shown), the conveyor belt is connected with the printing device and drives the printing device to move back and forth on the guide rail 8, the air-drying device includes a combination of the first fan assembly 21 and the second fan 21, and the feeding device includes Crimping wheel 34, crimping wheel fixed mount 35 and hexagonal axle 36, crimping wheel fixed mount 35 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com