Forming mechanism of pouch dispenser

A technology of forming mechanism and chartering machine, which is applied in the types of packaging items, packaging, transportation packaging, etc., can solve the problems of scattered materials, folding, low production efficiency, etc., to achieve stable and reliable movement, increase adjustment stroke, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

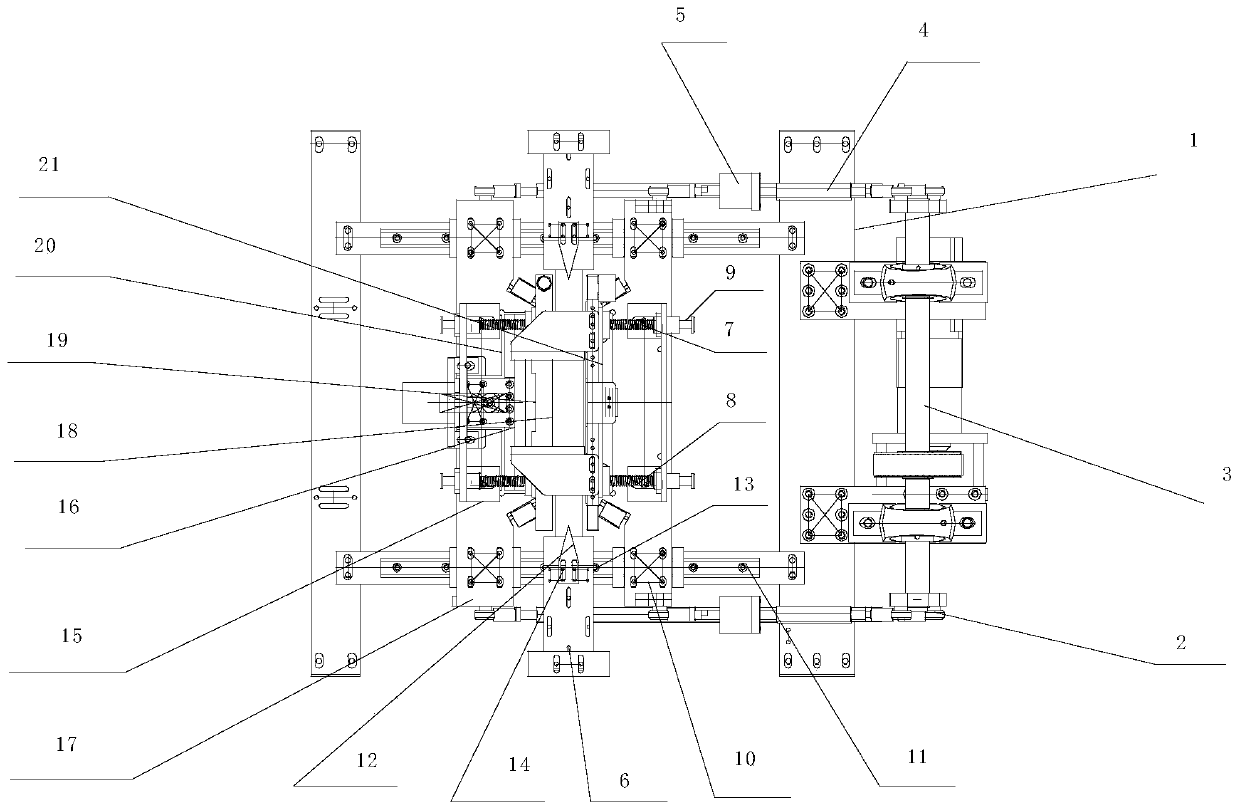

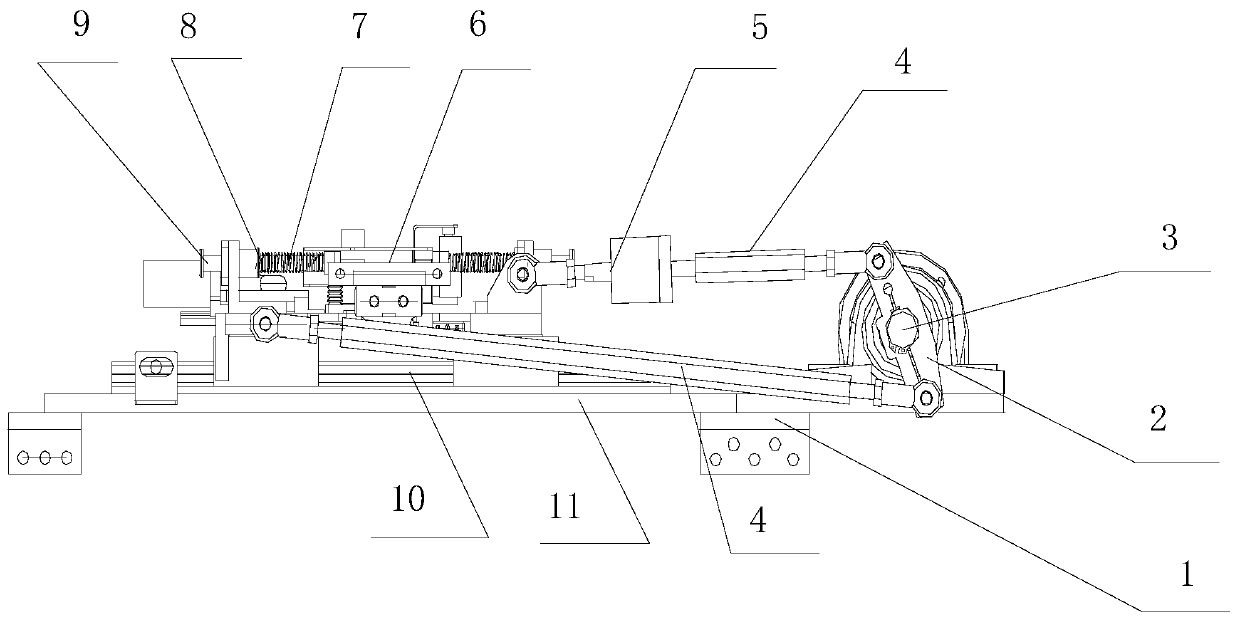

[0017] A forming mechanism of a chartering machine, which includes a fixing frame, a positioning adjustment device, an air suction device, a sealing and cutting device and a driving device. There are two lateral sliding rails 11, and two sliding blocks 10 are respectively installed on each of the sliding rails. The left and right adjustment plates 15 on the positioning and mounting plate of the left and right, the suction device is a suction box 16 communicated with the fan (not shown), the suction box is fixedly installed on the left positioning and mounting plate and is hinged There is a box cover (not shown), and the sealing and cutting device includes an upper sealing and cutting fixing plate 21, a lower sealing and cutting fixing plate 20, and an upper sealing and cutting knife 19 installed on the upper sealing and cutting fixing plate, respectively fixed on the left and right positioning mounting plates. and the lower sealing cutter 18 installed on the lower sealing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com