Connecting structure, hinged structure and adjusting support used for optical adjustment and sighting telescope

A technology of optical adjustment and connection structure, which is applied in the field of aiming devices, can solve the problems of small stroke, reduced aiming accuracy of the scope, and large volume of the scope, and achieve the effects of simple structure, convenient operation, stable movement and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] It should be noted that "first", "second" and similar words used in the present invention do not indicate any sequence, quantity or importance, but are only used to distinguish different components. "Up", "Down", "Left", "Right", "Front", "Back", "Top", "Bottom" etc. used in the present invention are only used to indicate the relative positional relationship, when the described object After the absolute position changes, the relative position relationship may also change accordingly.

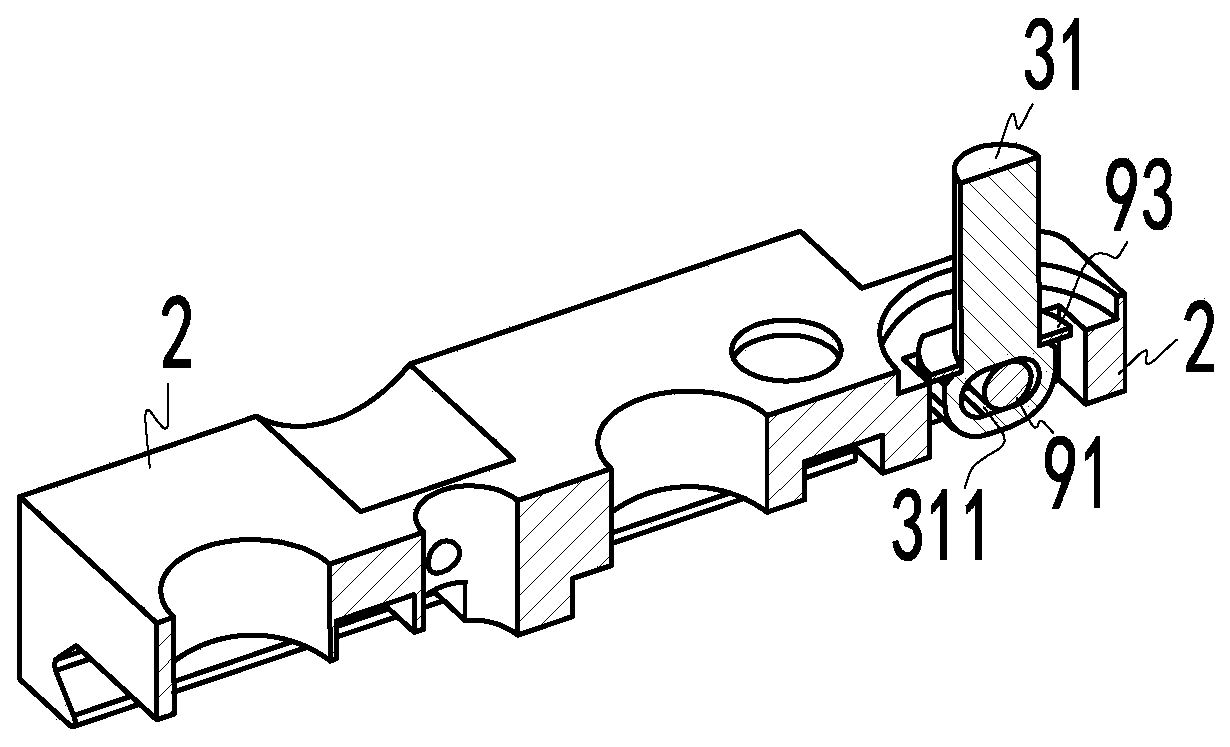

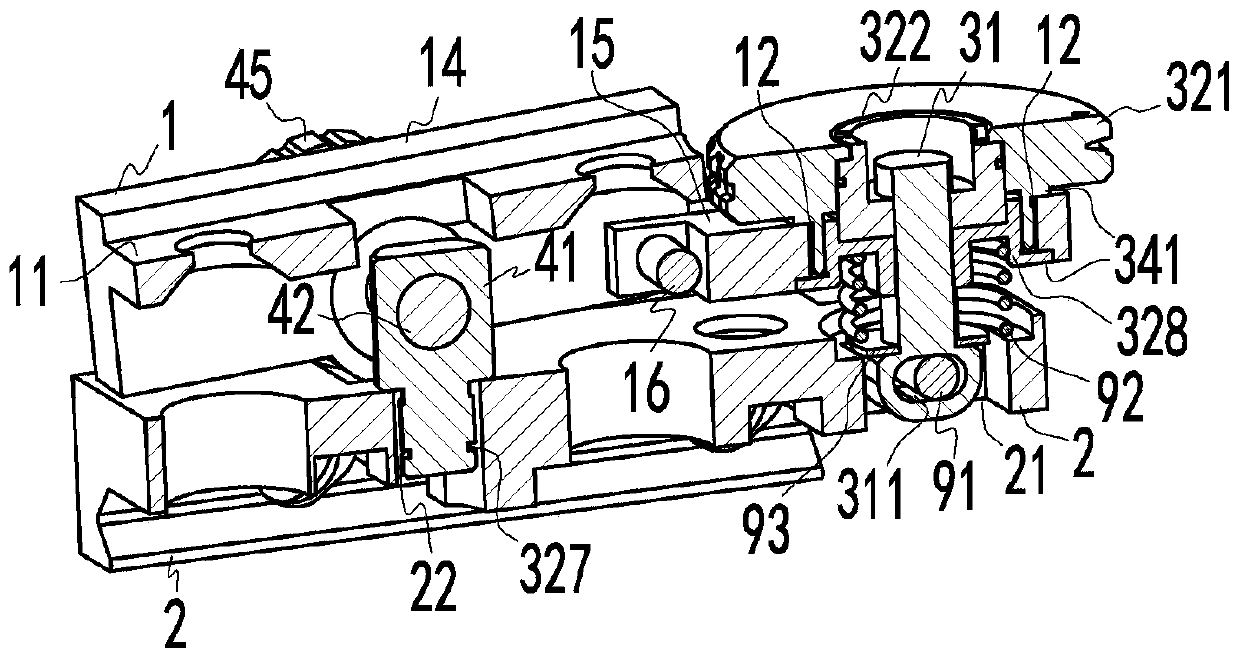

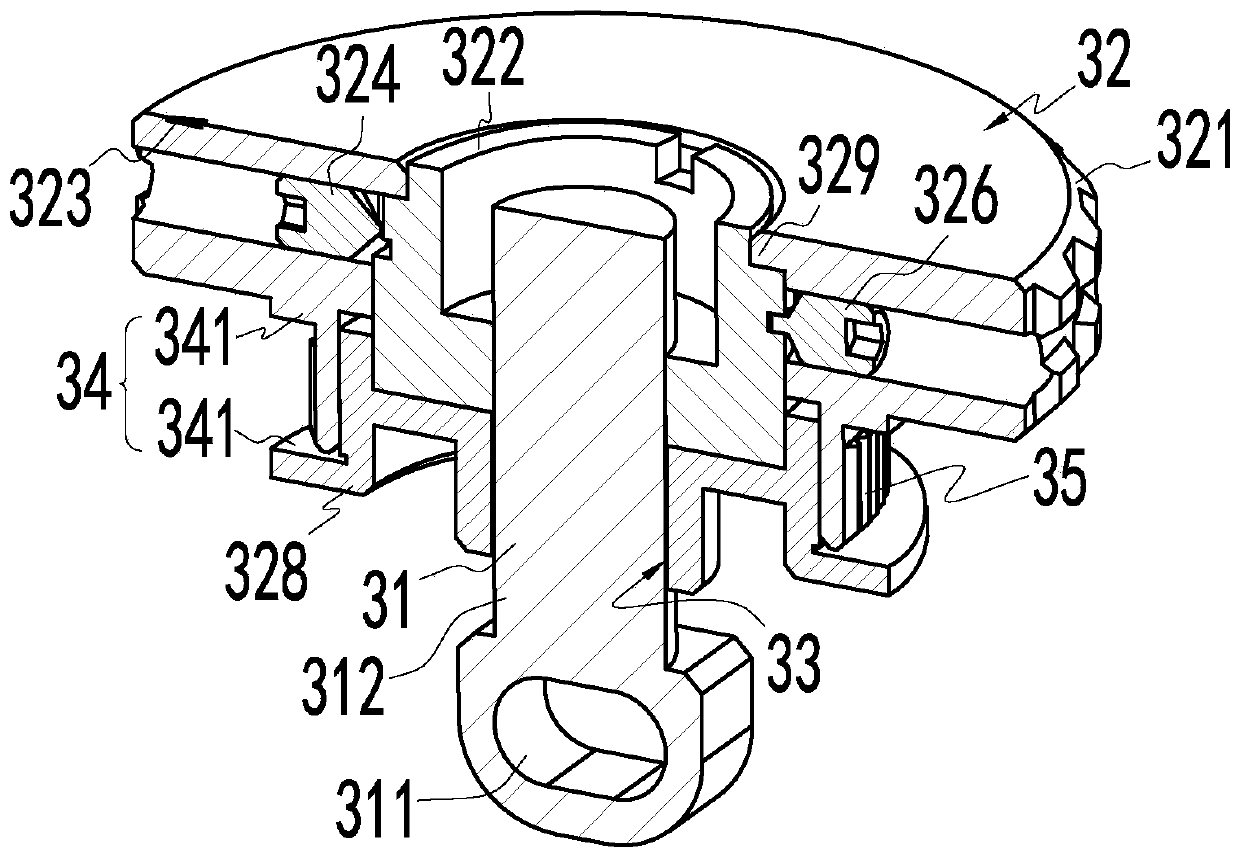

[0057] Such as figure 1 with figure 2 As shown, at least one embodiment of the present invention provides a connection structure for optical adjustment, which is used for the connection between the bracket body 1 and the bracket base 2, and can realize adjustment in a single direction (such as the up and down direction), which includes a first connecting column 31 and a handwheel device 32, the first connecting column 31 is used to connect the bracket seat 2, the handwheel device 32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com