Axle suspension system for multi-axle wheeled vehicles with high adjustment travel

A suspension system and axle technology, applied to vehicle parts, suspensions, axles, etc., can solve the problem of high cost, achieve high adjustment stroke, good self-adaptive ability, and improve driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

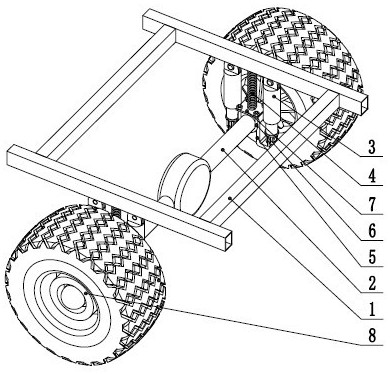

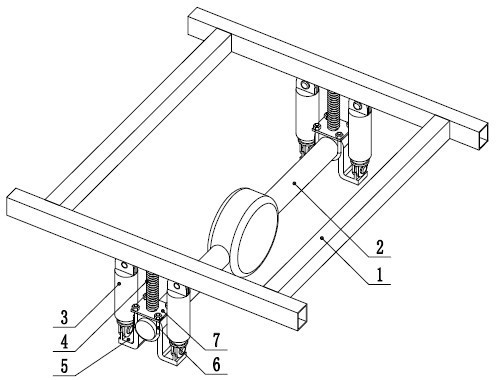

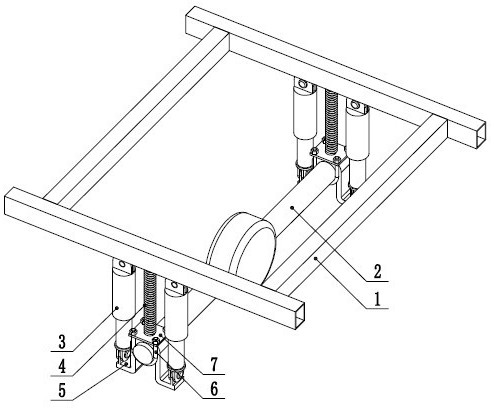

[0034] The present invention will be further described below by taking a crane as an embodiment.

[0035] In an example, as Figures 1~12 Shown: an axle suspension system of a multi-axle wheeled vehicle with a high adjustment stroke, including a frame 1 and an axle 2, and a hydraulic cylinder 3 is provided between the frame 1 and the axle 2 to bear the force, to The suspension structure buffered by the elastic member 4, the upper end of the hydraulic cylinder 3 is supported at the bottom of the frame 1, the lower end is supported at the side of the axle 2, and the lower end of the hydraulic cylinder 3 is located lower than the axle 2 height of the axis. The hydraulic cylinder 3 in this embodiment is not directly supported above the axle 2, but is supported on the side of the axle 2 to ensure that the hydraulic cylinder 3 has a larger size and stroke, so that the axle 2 has a higher vertical height. With a high adjustment stroke, when the axles 2 of the multi-axle wheeled veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com