Shaft sleeve structure for installing air duct switching device and air duct switching device

A technology for converting devices and air supply ducts, which is applied to washing devices, textiles and papermaking, and household appliances, and can solve the problems of increased structural size, increased number of equipment, and increased occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

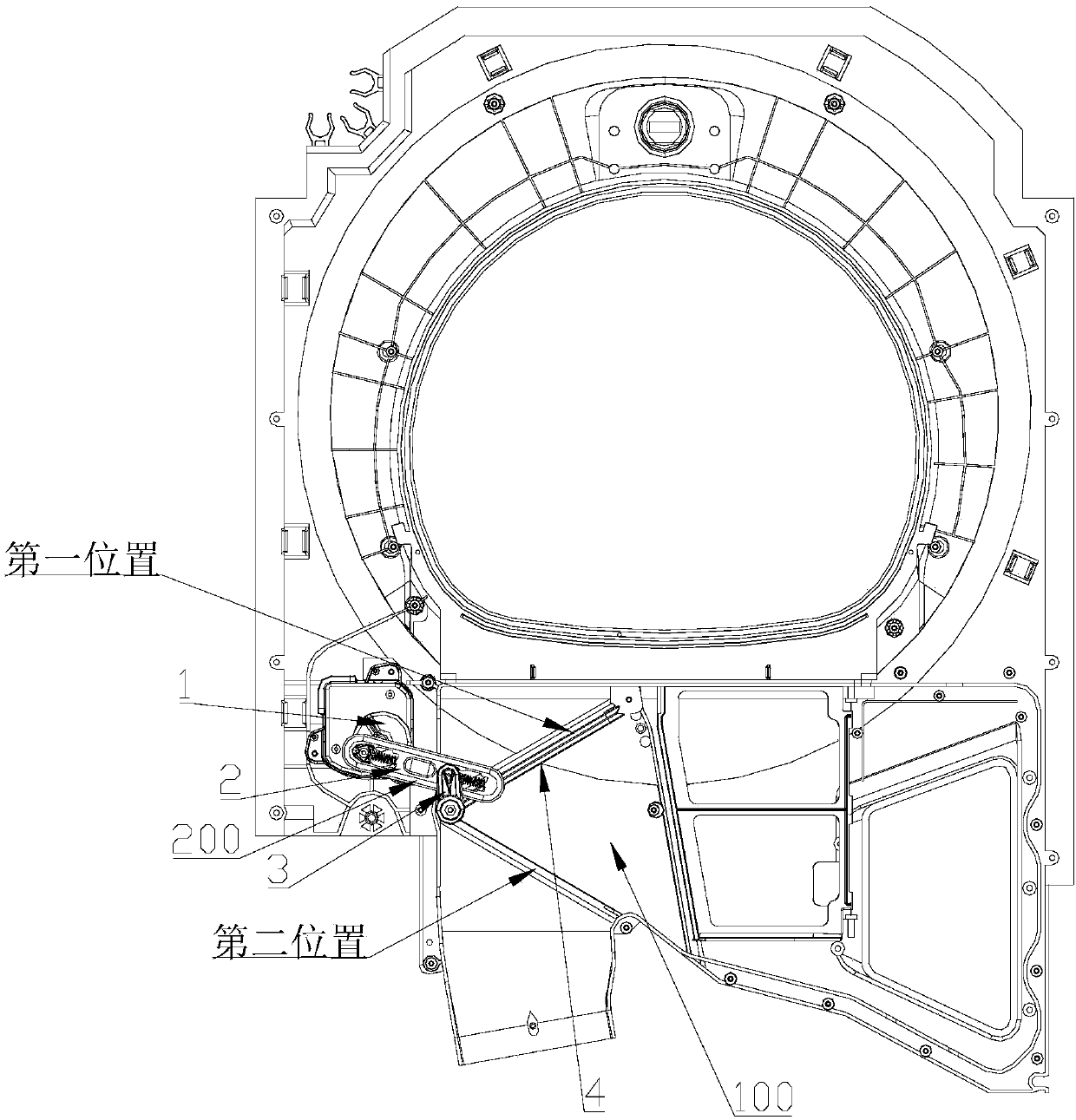

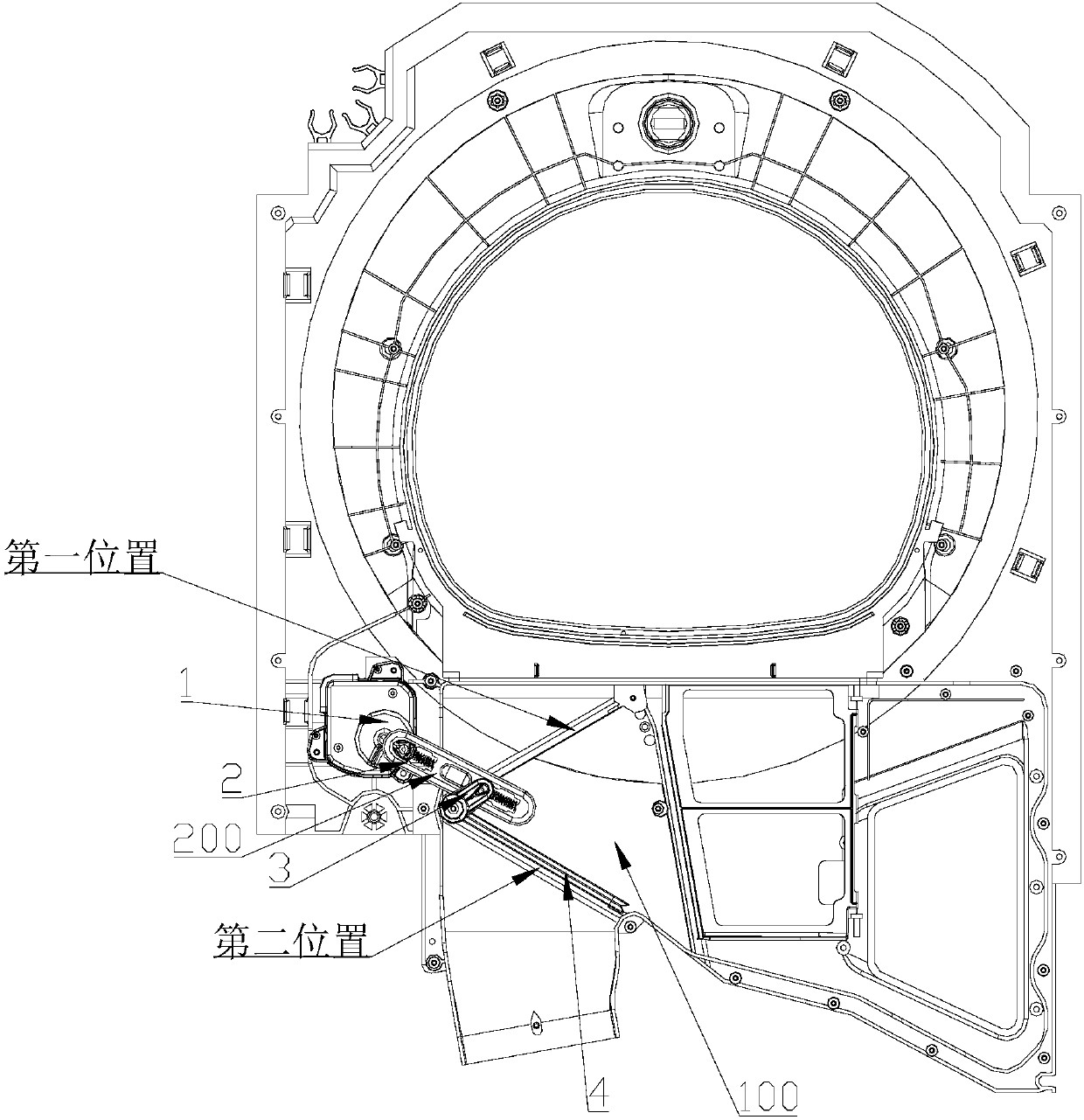

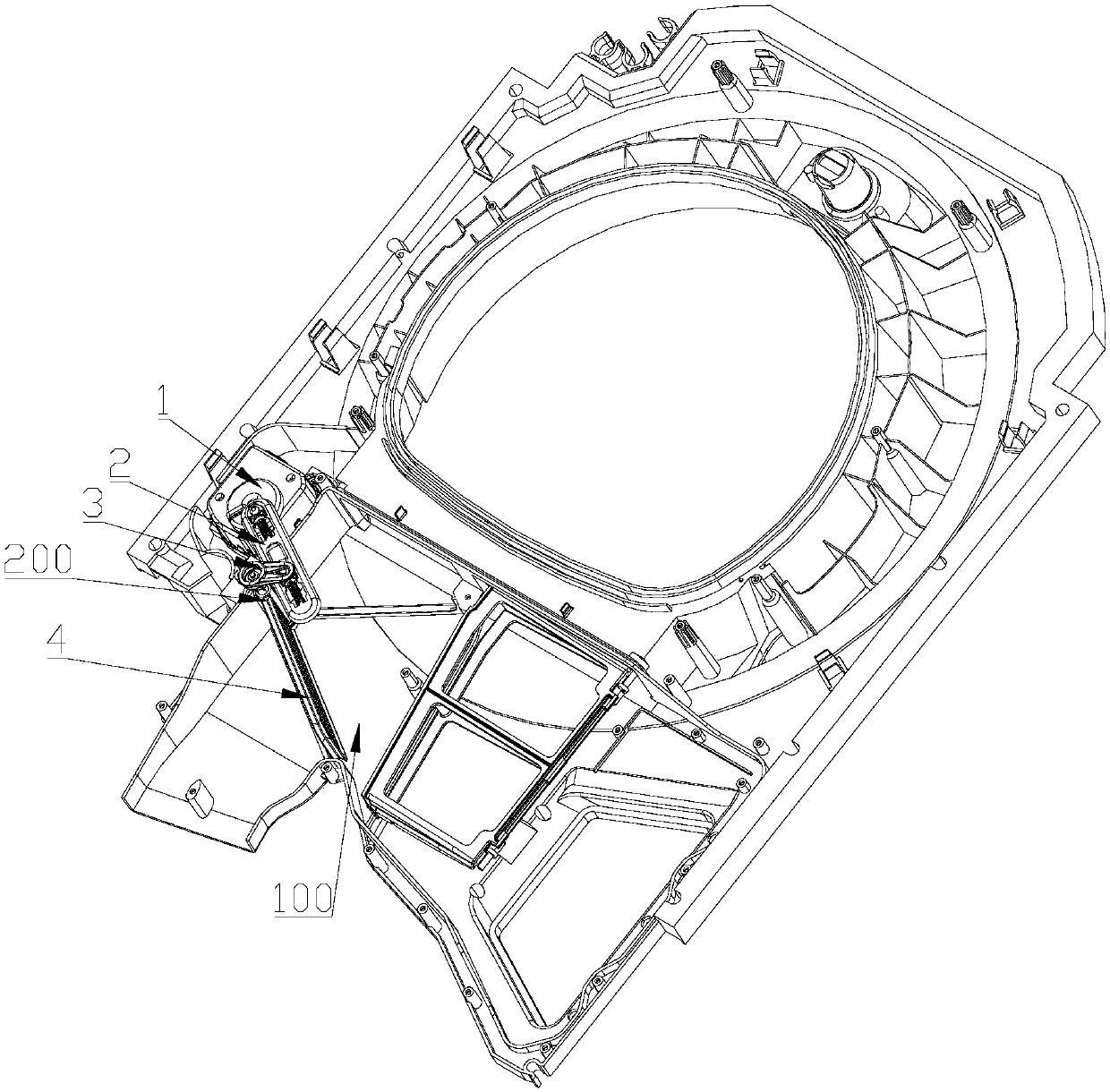

[0060] Such as Figure 1 to Figure 6 As shown, in this embodiment, a shaft sleeve structure for installing the baffle shaft of the air duct conversion device is introduced. One end of the air duct baffle 4 is provided with a baffle shaft 411 extending horizontally to both sides, and the baffle shaft 411 is connected to the The two side walls of the air duct 100 are correspondingly plugged and fixed so that the baffle 411 is relatively rotatably installed in the air duct 100 ; The air duct side wall 101 is provided with a mounting groove 203, and the mounting groove 203 is inserted and fixed with a non-circular bearing sleeve 204, and the bearing sleeve 204 is provided with a baffle shaft 411 for the air duct baffle plate 4 to be plugged in correspondingly. The mounting holes 205.

[0061] A detachable bearing sleeve is provided on the side wall of the air duct to facilitate the detachable replacement of the bearing of the air duct reversing device, and achieve the purpose of ...

Embodiment 2

[0071] Such as Figure 1 to Figure 3 ,Such as Figures 7 to 11 As shown, in this embodiment, an adapter 3 for an air duct conversion device is introduced. The two ends of the adapter 3 are respectively provided with an adapter shaft 31 and an adapter sleeve 32. The adapter shaft 31 and the air duct conversion device The connecting crossbeam 2 of 200 is connected rotatably around the axis, and the adapter sleeve 32 is fixedly connected with the air duct baffle plate 4 of the air duct converting device 200 in a non-rotatable manner.

[0072] By setting the above-mentioned adapter on the air duct conversion device, two different plug-in structures are integrated on the adapter, so as to ensure that the two ends of the adapter are rotatably connected to different components and cannot be rotated relative to each other. connection to achieve the purpose of driving the air duct baffle of the air duct conversion device.

[0073] Such as Figure 8 To such as Figure 10 As shown, i...

Embodiment 3

[0082] Such as image 3 , Figure 7 and Figure 12 to Figure 14As shown, this embodiment introduces an air duct baffle 4 of an air duct conversion device 200, which includes a baffle body 41 and a frame 42, and one side of the baffle body 41 is provided with a baffle shaft extending horizontally to both sides. 411 , the frame wraps the three sides of the baffle body except the baffle shaft 411 . The baffle body 41 and the baffle shaft 411 are integrally arranged, and are driven by the motor 1 to rotate together to realize the opening and closing of the air duct 100 .

[0083] In this embodiment, the air duct switching device 200 is fixed on the housing through a fixing device, and the air duct baffle 4 switches and moves between the first position and the second position to realize the opening and closing of the air duct 100, and the gas flows through the air duct. Under the interaction between the side wall and the air duct baffle 4, the gas can only flow along the prescri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com