Assembled standard layer module and standard layer construction method combining dry and wet processes

A construction method and assembled technology, which can be used in building construction, architecture, building materials, etc., and can solve the problems of unsatisfactory joint strength and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

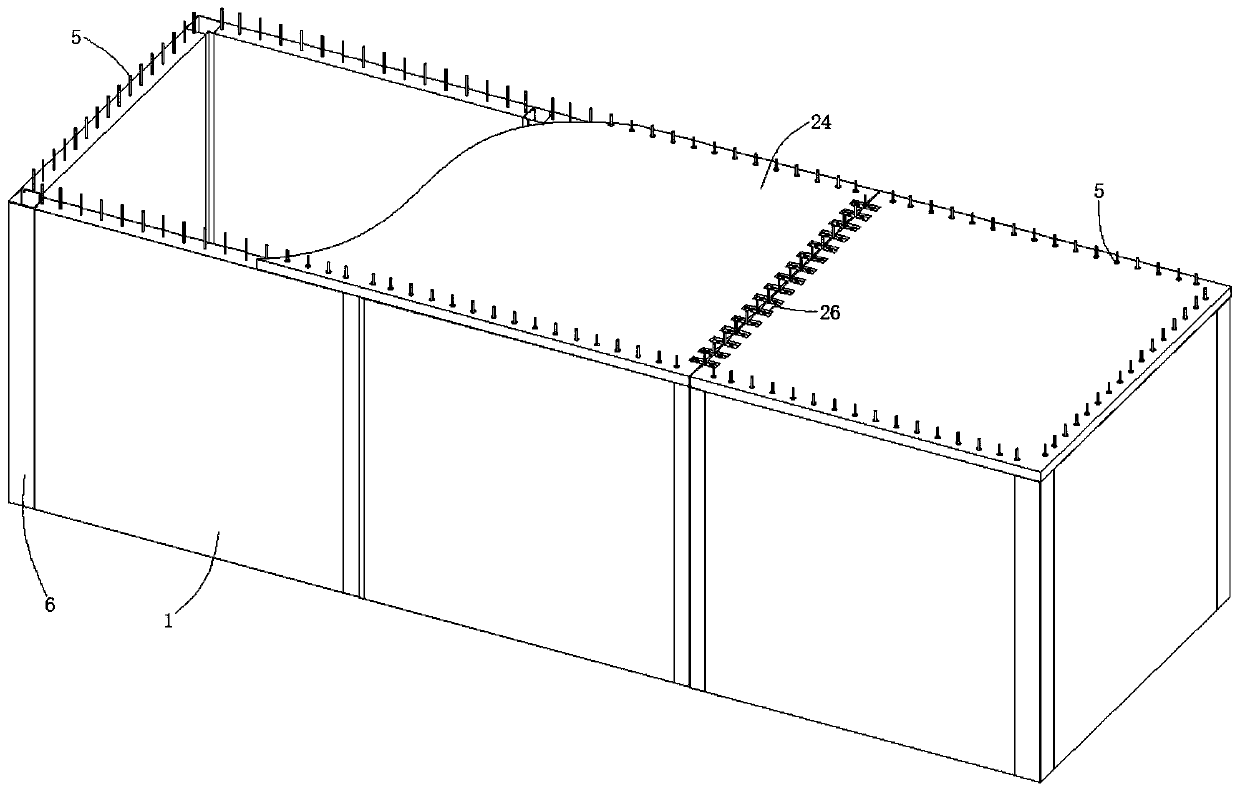

[0063] This embodiment provides an assembled standard layer module to solve the above-mentioned deficiencies in the prior art. The present invention can realize faster assembly of floor slabs and improve the quality of floor slab assembly, such as Figure 1-Figure 15 As shown, specifically set to the following structure:

[0064] Including assembled prefabricated wall panels and integral assembled floor slabs.

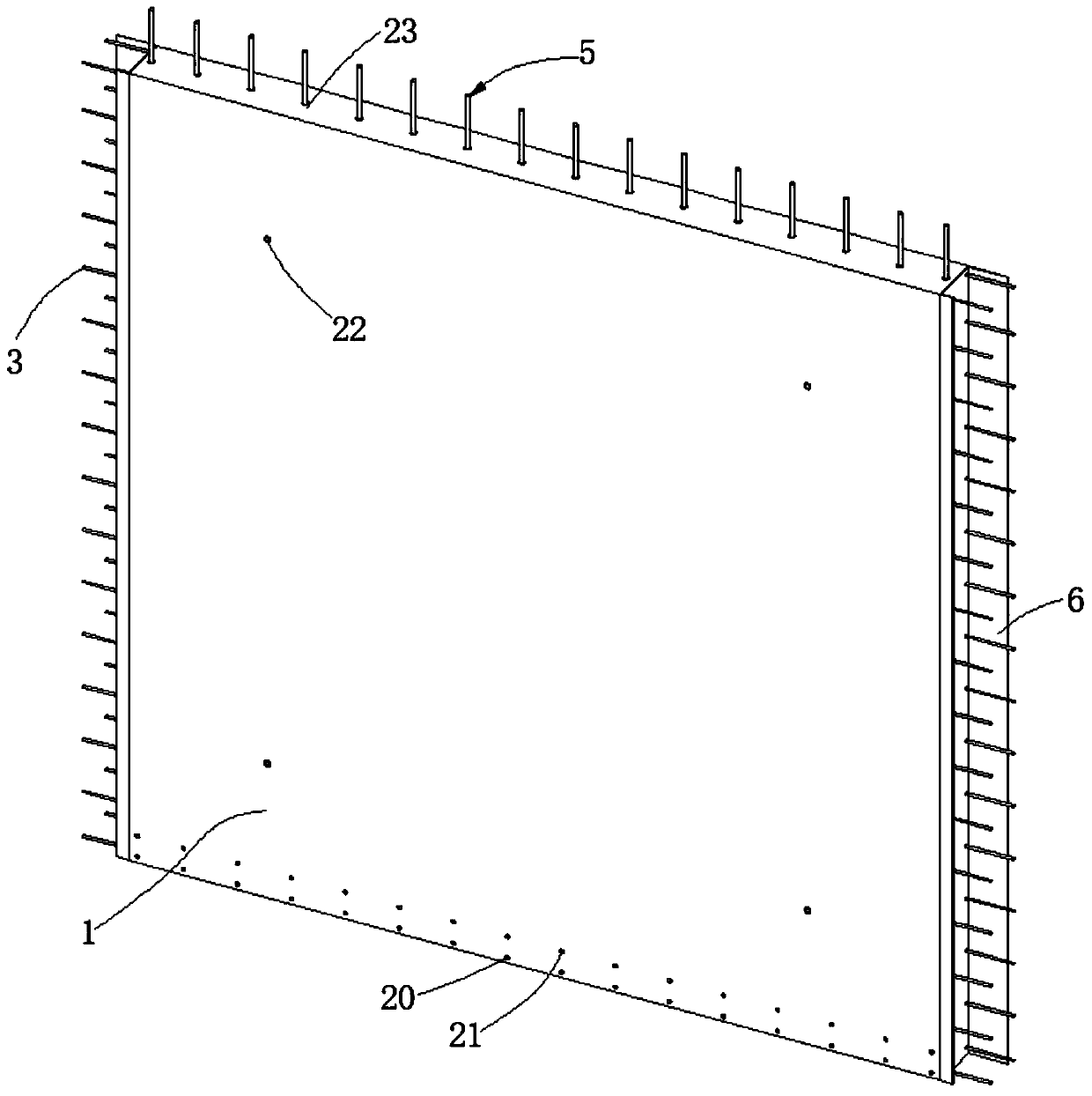

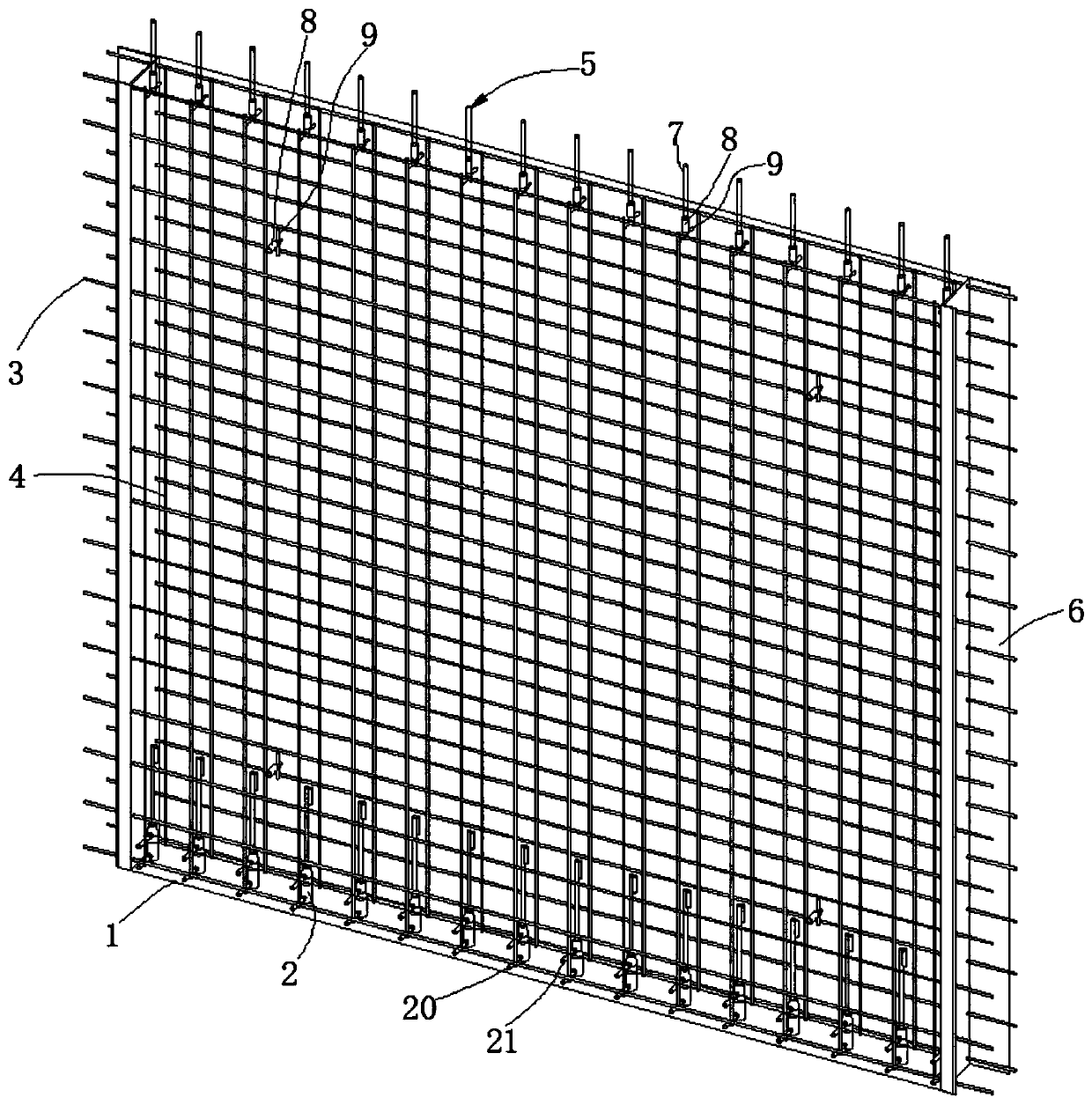

[0065] The assembled prefabricated wall panels include concrete wall panels 1, horizontal steel bars 3 and longitudinal steel bars 4, and the concrete wall panels 1 can be load-bearing wall panels or lightweight concrete wall panels with concealed beams on the upper part. Before the concrete wall panel 1 is prefabricated, horizontal steel bars 3 and longitudinal steel bars 4 are laid horizontally and vertically in the mold to form a steel mesh. Plate 1 body. For the convenience of description, this embodiment takes a vertical rectangular concrete wall panel as an ex...

Embodiment 2

[0074] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, especially adopt the following configuration structure:

[0075] The integral assembled floor slab also includes a connecting steel sheet 30 for connecting two adjacent concrete floor slabs 24 . After using the connecting steel sheet 30 , the structure of the concrete floor slab 24 needs to be adjusted.

[0076] The rectangular connecting steel sheet 30 has three through holes, which are arranged sequentially along the length direction of the connecting steel sheet 30; a pin joint hole 25 is reserved at the edge of at least one side of the concrete floor 24, and no The side of the concrete floor 24 of the pin connection hole 25 is provided with embedded anchor bolts 27 whose heads extend vertically from the surface of the concrete floor 24. The embedded anchor bolts 27 are arranged in sequence along the direction of the edge of the concre...

Embodiment 3

[0079] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, it can realize rapid positioning and installation of wall panels, can improve the strength and durability of nodes, and can realize dryness when assembling walls. The combination of wet process has the advantages of high construction efficiency, especially the following setting structure is adopted:

[0080] The assembled prefabricated wall panel also includes a steel frame 6, and the steel frame 6 includes a bottom plate 6a and a first wing plate 6b and a second wing plate 6c respectively connected to the two side edges of the bottom plate 6a, the first wing plate 6b and the second wing plate 6c A channel-shaped steel structure with an inner groove is formed on the same side of the bottom plate 6a. The steel frame 6 can be welded by at least three steel plates. If conditions permit, the whole steel plate can also be integrally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com