Floor with cracks and preparation method of floor

A technology for cracks and floors, which is applied in the field of cracked floors and its preparation, and can solve problems such as lack of other elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

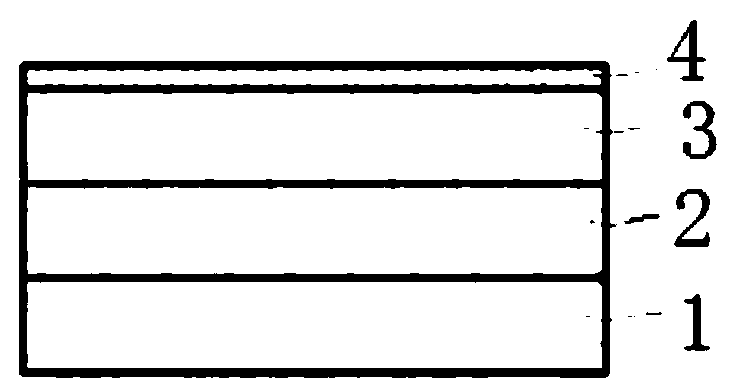

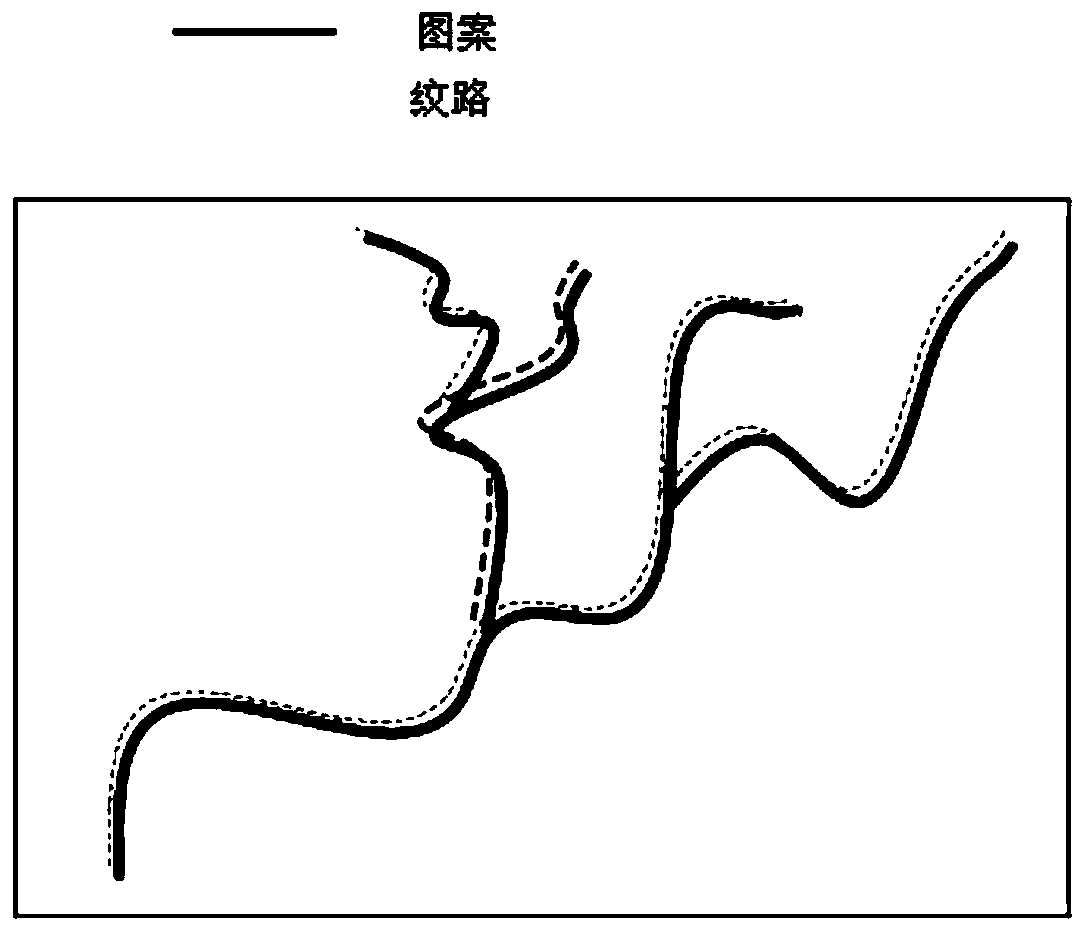

[0031] Such as figure 1 with 2 As shown, a floor with cracks includes a substrate layer 1, a pattern layer 2 is attached to the substrate layer 1, a paint cracking layer 3 is provided on the pattern layer 2, and a transparent protective layer 4 is provided on the paint cracking layer 3.

[0032] Wherein, the paint cracking layer 3 is a flat paint finish layer with cracks, the paint cracking layer 3 corresponds completely or partially to the texture of the pattern layer 2, the pattern layer 2 is a printed pattern layer and forms a printed pattern, and the base material layer 1 is PVC. Any one of substrates, PET substrates, PP substrates, magnesium substrates, pressure boards and wood boards, the transparent protective layer 4 can be UV paint or PUR paint. And for visual effect, also can be additionally provided with the pearlescent powder or bright sheet with decorative effect in the cracked paint layer. In this embodiment, the cracked paint layer is one layer. When the crack...

Embodiment 2

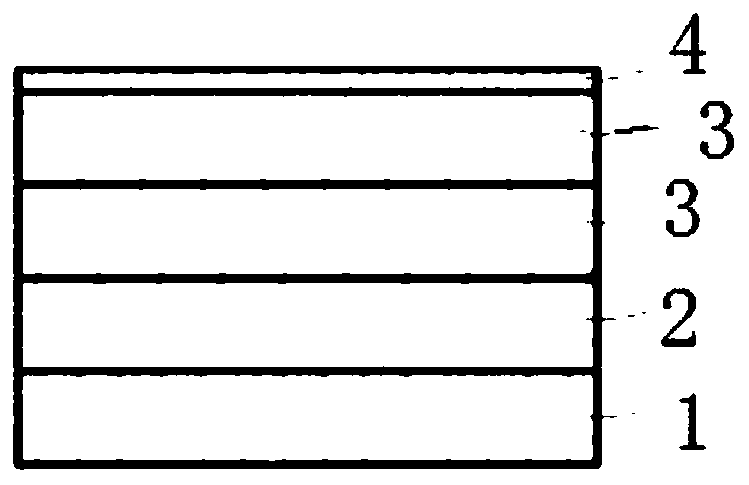

[0036] Such as image 3 As shown, a floor with cracks includes a substrate layer 1, a pattern layer 2 is attached to the substrate layer 1, a paint cracking layer 3 is provided on the pattern layer 2, and a transparent protective layer 4 is provided on the paint cracking layer 3. Wherein, the cracked paint layer is a flat paint surface layer with cracks, the cracked paint layer corresponds completely or partially to the texture of the pattern layer, the pattern layer is a film with a pattern, the base layer is a PVC substrate, and the transparent protective layer is a UV paint. And for visual effects, the cracked paint layer contains pearlescent powder or bright sheets with decorative effect. Further, the cracked paint layer has two or more layers, and the two cracked paint layers are layered with different colors of cracked paint layers sequentially to present more than two color effects. Cracks of different widths can also be set on the cracked paint layers of different col...

Embodiment 3

[0040] Such as Figure 4-5 As shown, a floor with cracks comprises a substrate layer 1, a film 2 with a pattern is attached on the substrate layer 1, the film 2 is roll-coated with UV paint for adhesion, and the UV paint for adhesion is flow-coated The transparent paint cracking layer 3 is provided with a protective UV paint 4 on the transparent paint cracking layer 3 . The transparent cracked paint layer is a transparent cracked paint layer cracked into cracks. The depth of the crack is 0.1-1.5mm, and the width is 0.1-1.5mm. And for visual effects, the cracked paint layer contains pearlescent powder or bright sheets with decorative effect. Further, the cracked paint layer has two layers, and the two cracked paint layers are layered with different colors of cracked paint layers sequentially to present more than two color effects.

[0041] The preparation method is as follows. In the first step, PVC, stone powder, stabilizer, and lubricant are stirred and mixed in a ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com