Adjustable folding-type steel column welding mounting platform and construction method thereof

An installation platform and foldable technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc., can solve the problems of high construction cost, complicated installation, poor adaptability, etc., to reduce the cost of transshipment and the reduction of land occupation. Area, highly adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

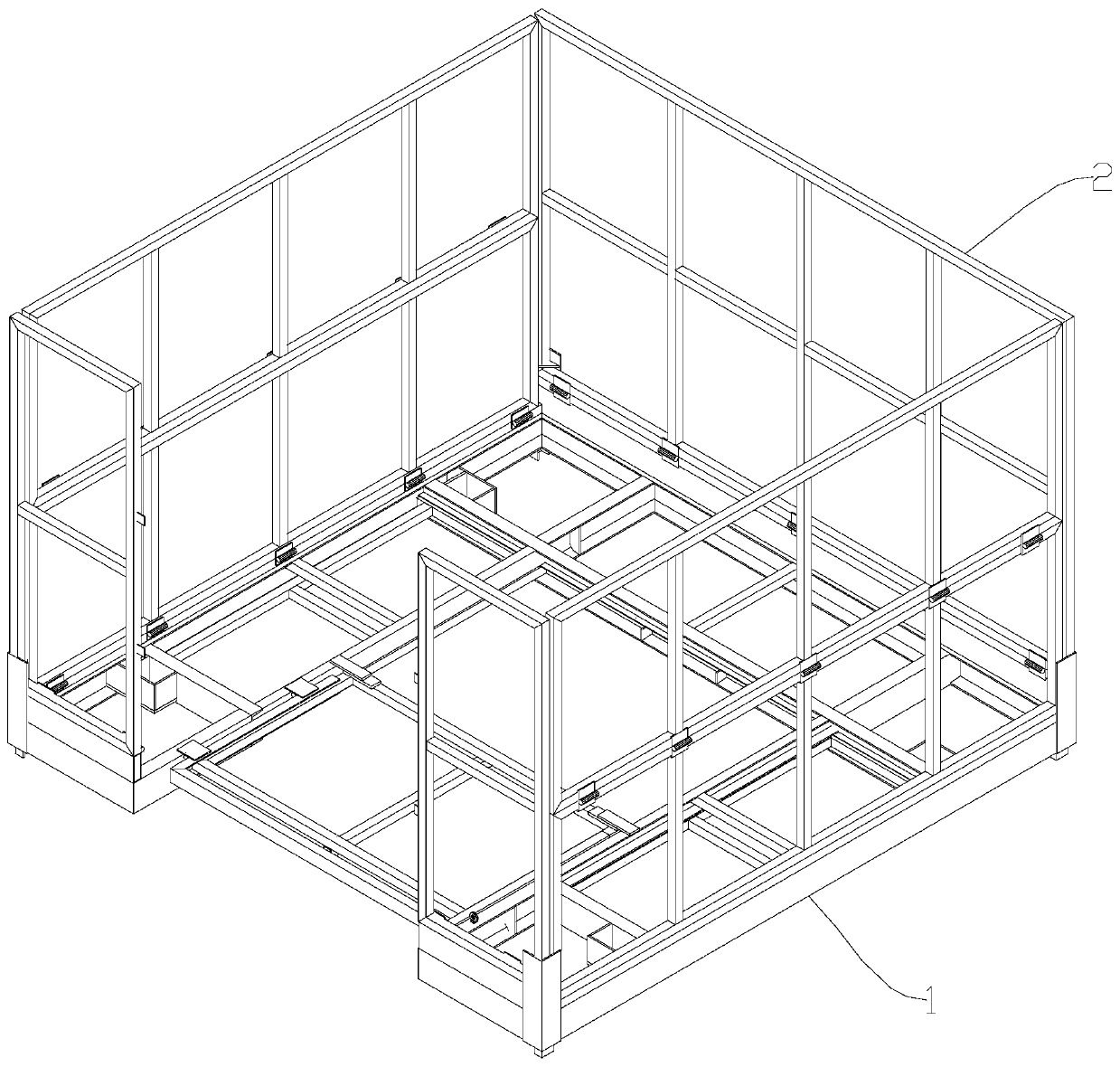

[0054] Such as figure 1 As shown, an adjustable folding steel column welding installation platform provided in a preferred embodiment of the present invention, its main structure includes two parts: a bottom frame structure 1 and an enclosure structure 2 . Among them, the bottom frame structure 1, as the overall support structure, plays the role of bearing the weight of the construction personnel and equipment above, and the enclosure structure 2 is installed on the bottom frame structure 1, which plays a protective role around it and prevents personnel and sundries from falling .

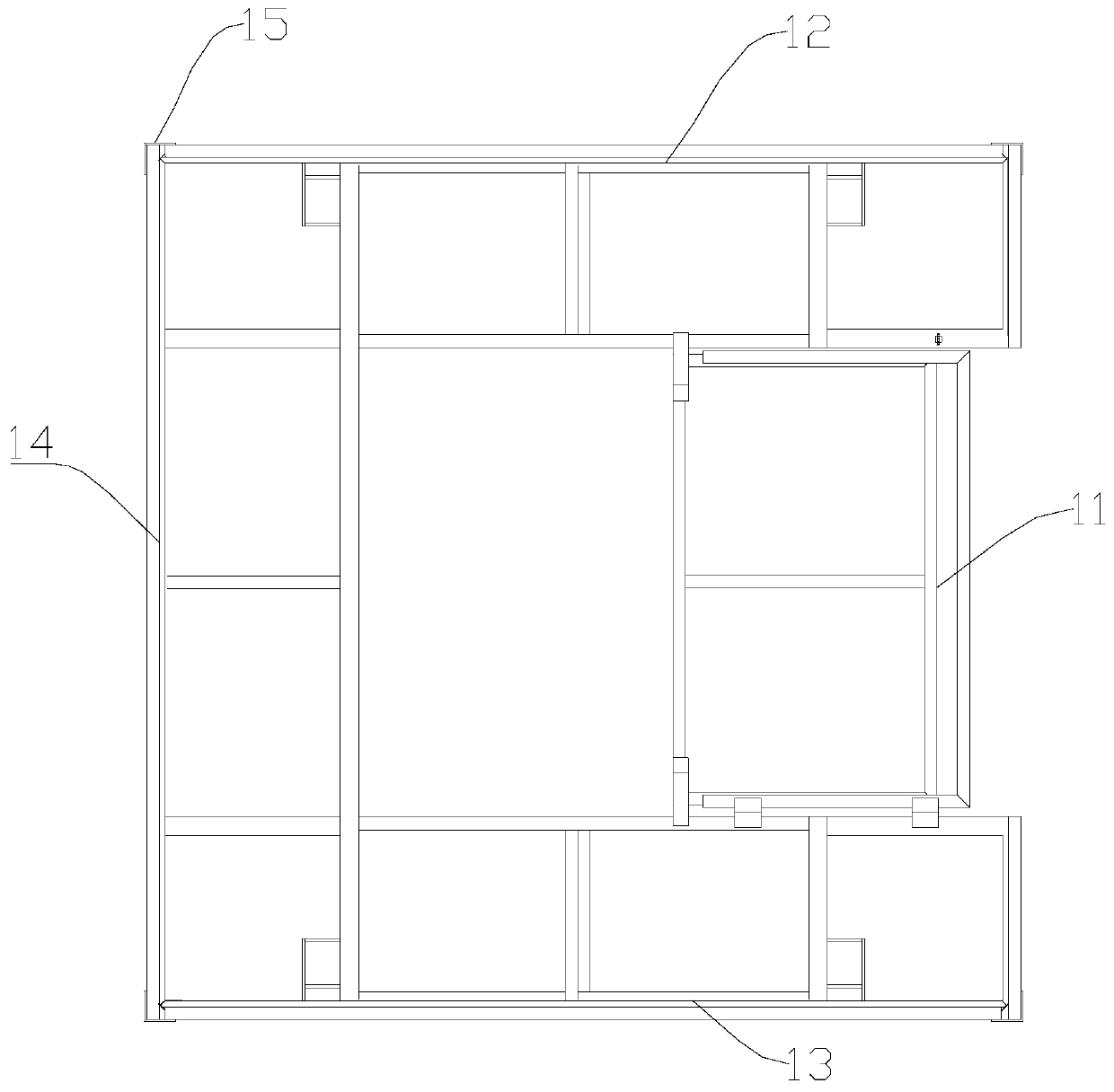

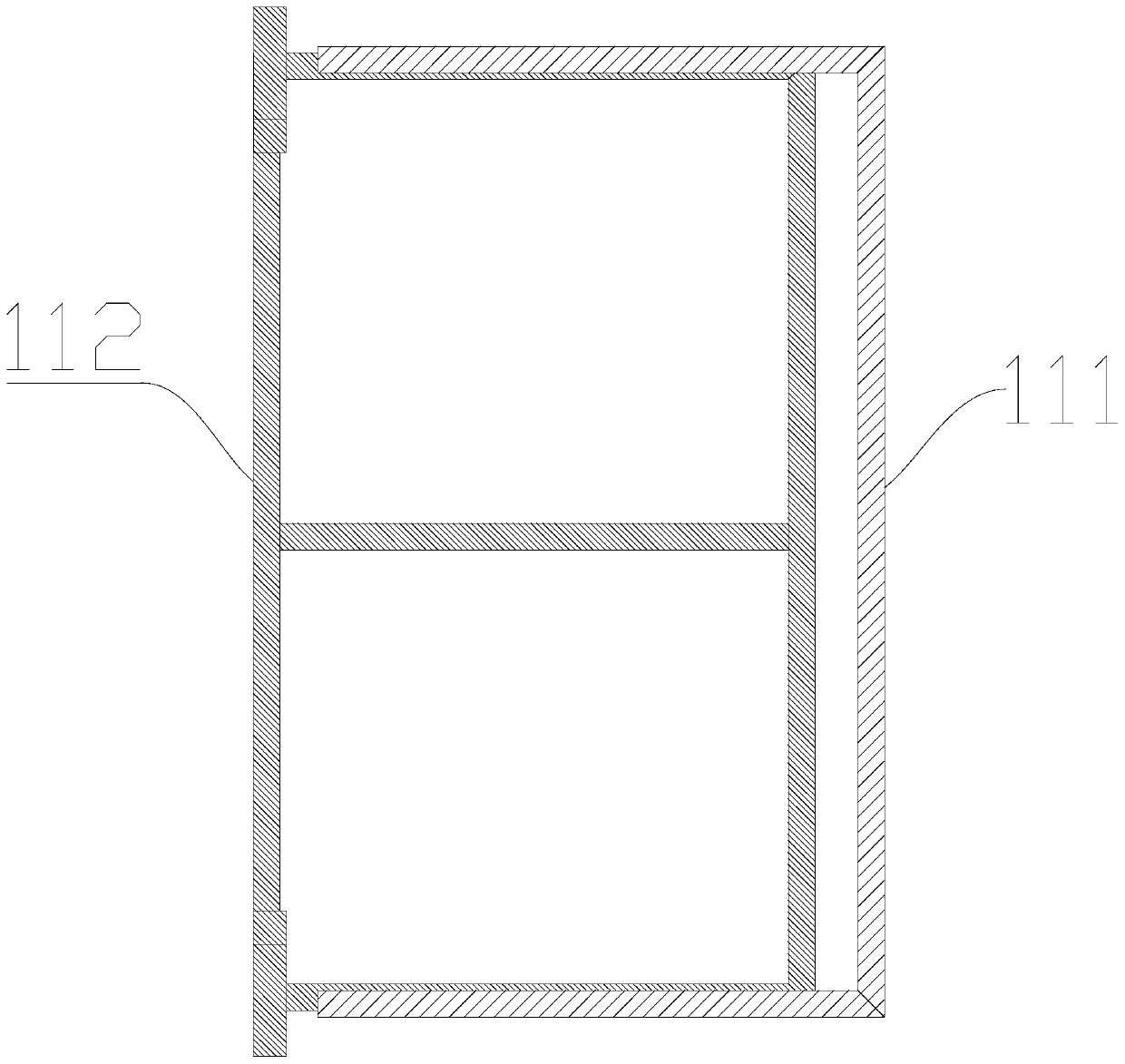

[0055] Such as figure 2 As shown, the bottom frame structure 1 includes a folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com