High-evacuation-rate high-pressure starting box

A high-pressure starting and emptying rate technology, which is applied to machines/engines, rocket engine devices, jet propulsion devices, etc., can solve problems such as affecting the inversion performance of the capsule, uneven pressure on the surface of the capsule, and adverse effects on the liquid emptying rate. Achieve the effect of improving the working life of the starting box, good pressure equalization effect, and improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

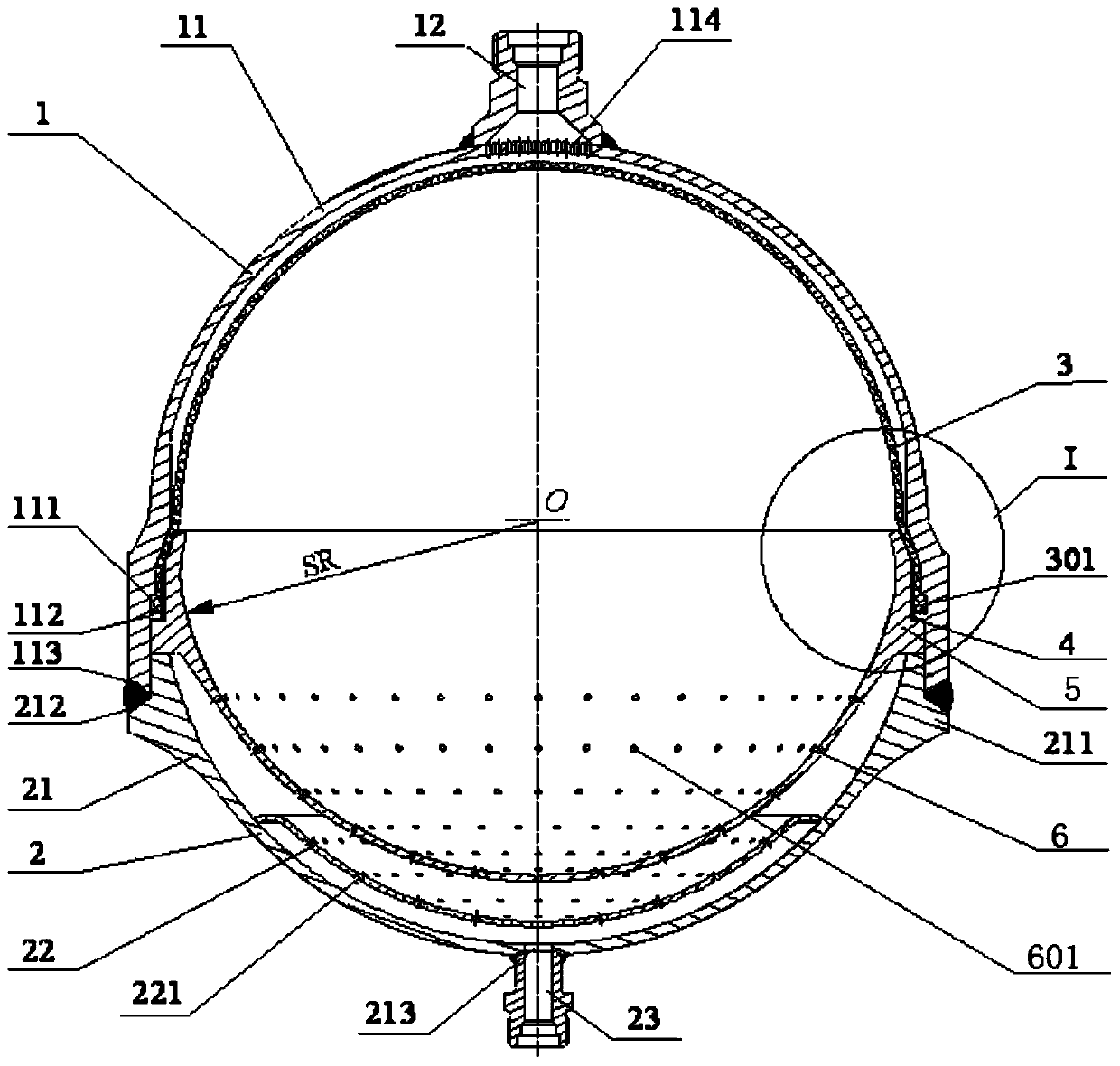

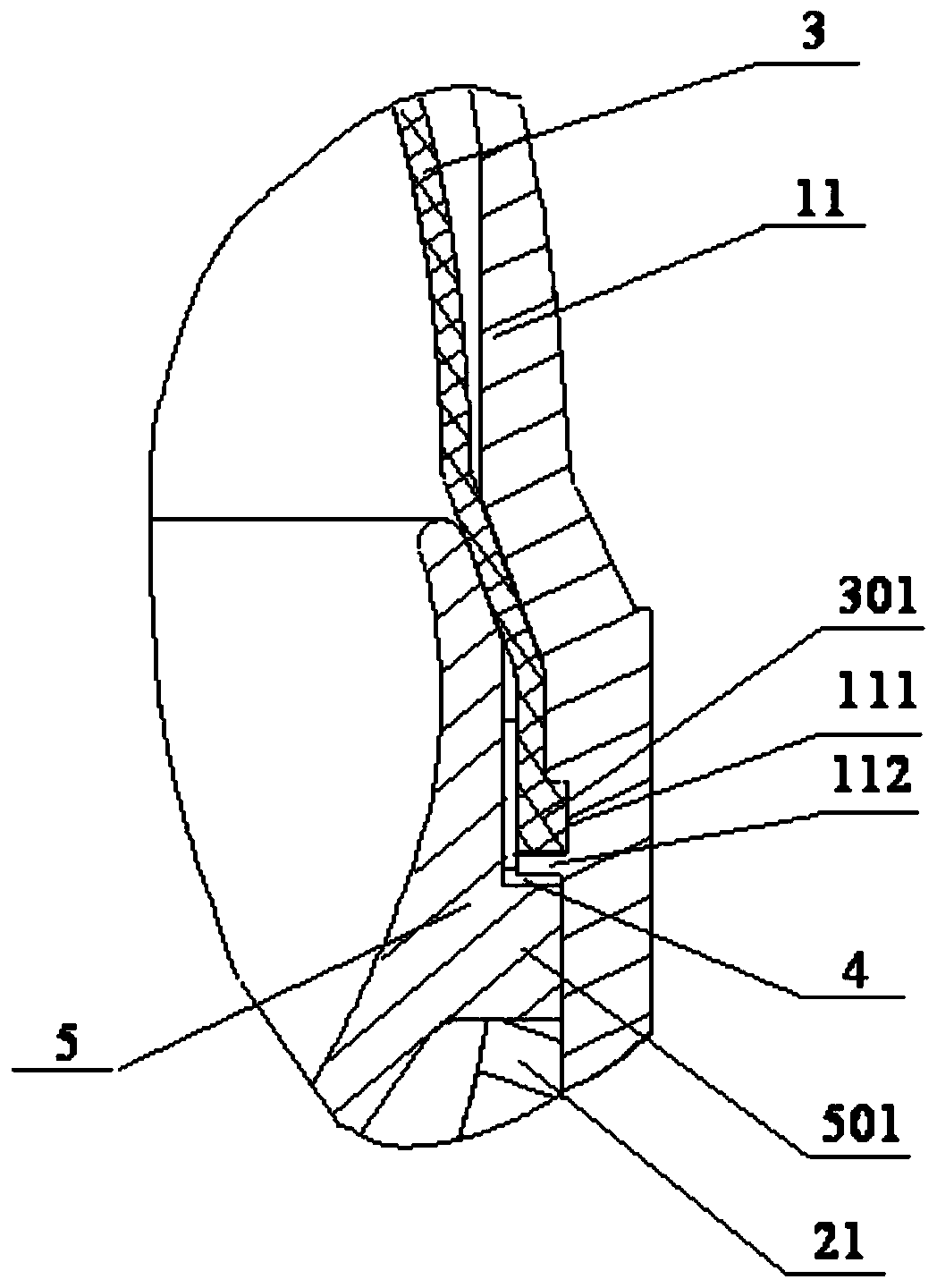

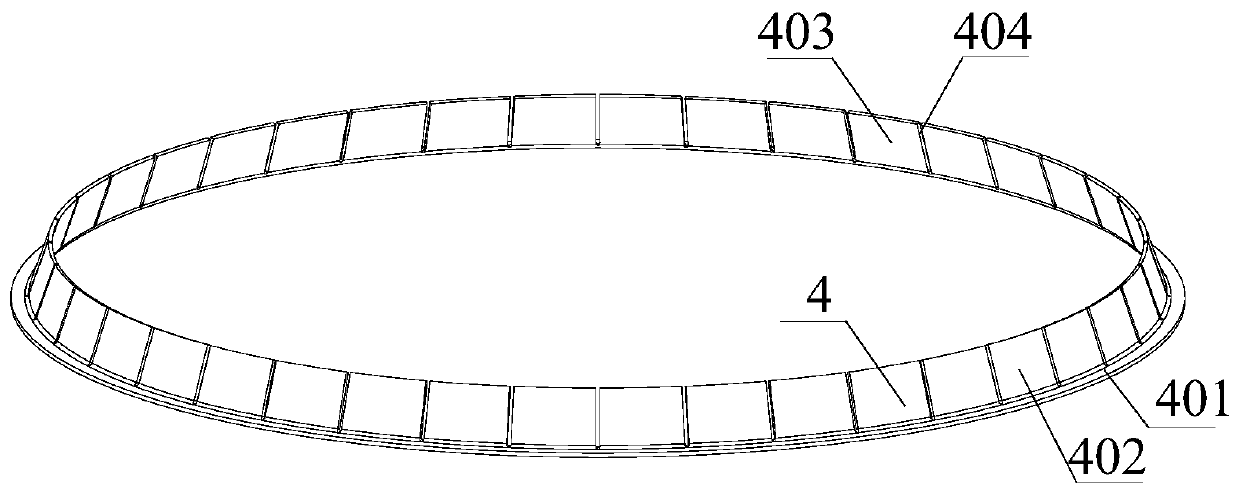

[0032] like Figure 1-Figure 3 As shown, the high-pressure starter box includes a liquid chamber assembly 1 , an air chamber assembly 2 , a capsule 3 , a capsule compression ring 5 and a first-stage flow equalizing plate 6 .

[0033]Wherein, the liquid chamber assembly 1 includes a first hemispherical shell 11 and a liquid nozzle 12 welded on the first hemispherical casing 11, the liquid nozzle 12 is used for filling and supplying liquid, and a three-way nozzle ( (not shown) for connecting the liquid nipple to the starter tank fill line and the starter tank supply line. The inner side of the first hemispherical shell 11 is provided with an annular groove 111 and a first annular shoulder 112 near the open end. The first annular shoulder 112 is arranged closer to the open end than the annular groove 111. The opening of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com