Oil-tight vibration exciter and vibrating screen

A vibration exciter, oil leakage technology, applied in the direction of filter screen, engine components, engine lubrication, etc., can solve the problems of reduced life, waste of lubricating oil, weakened bearing lubrication, etc. The effect of reducing the defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

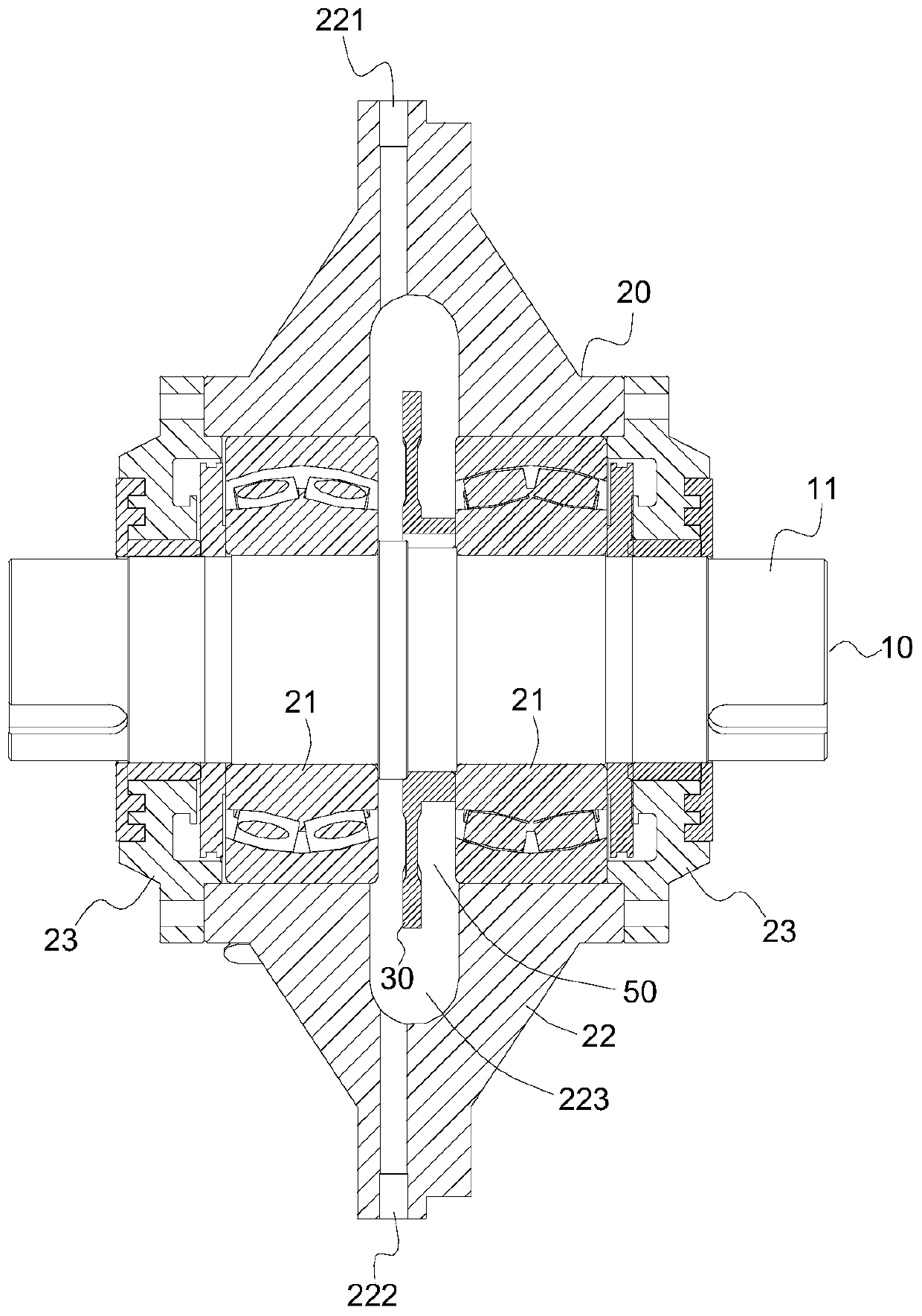

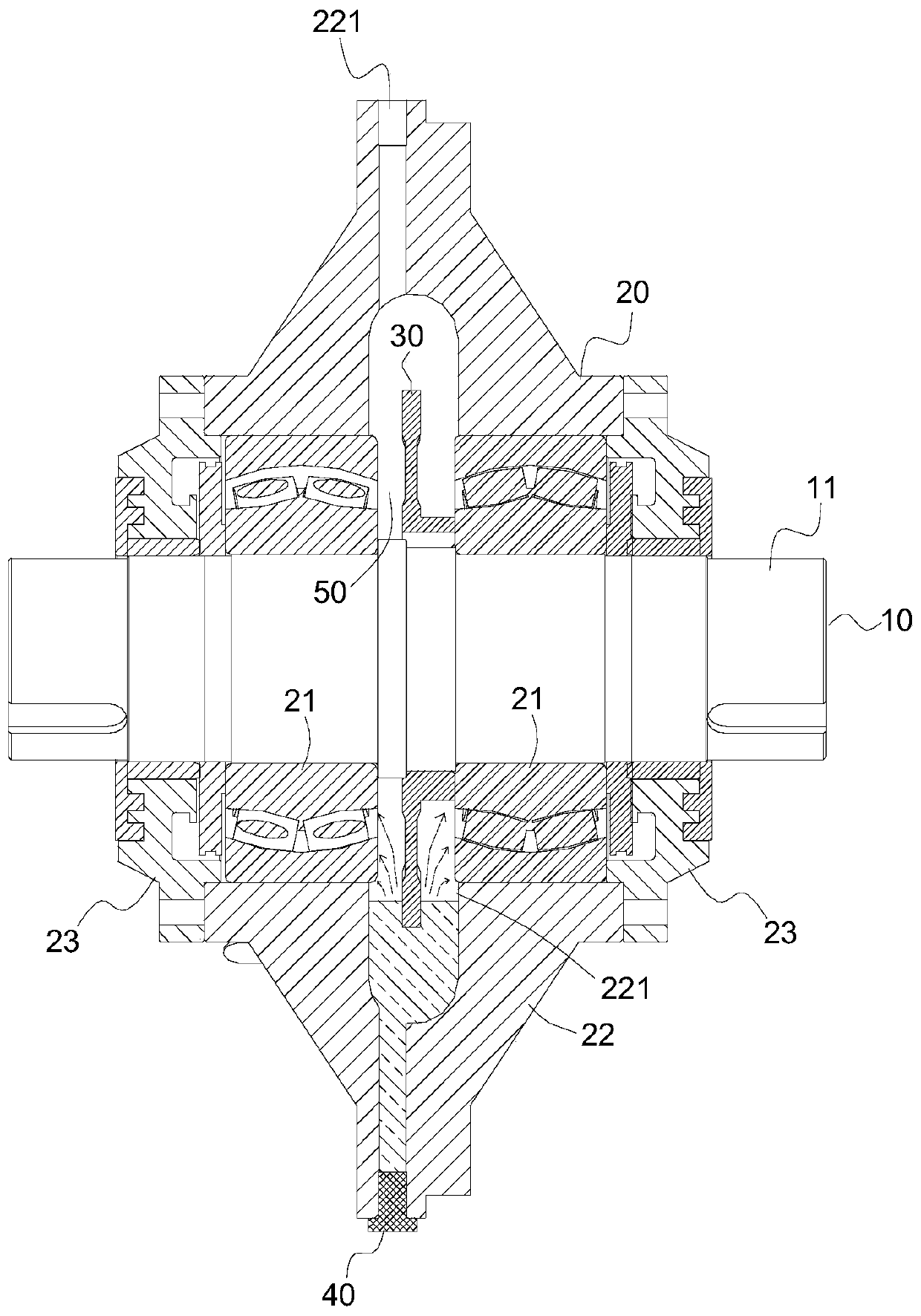

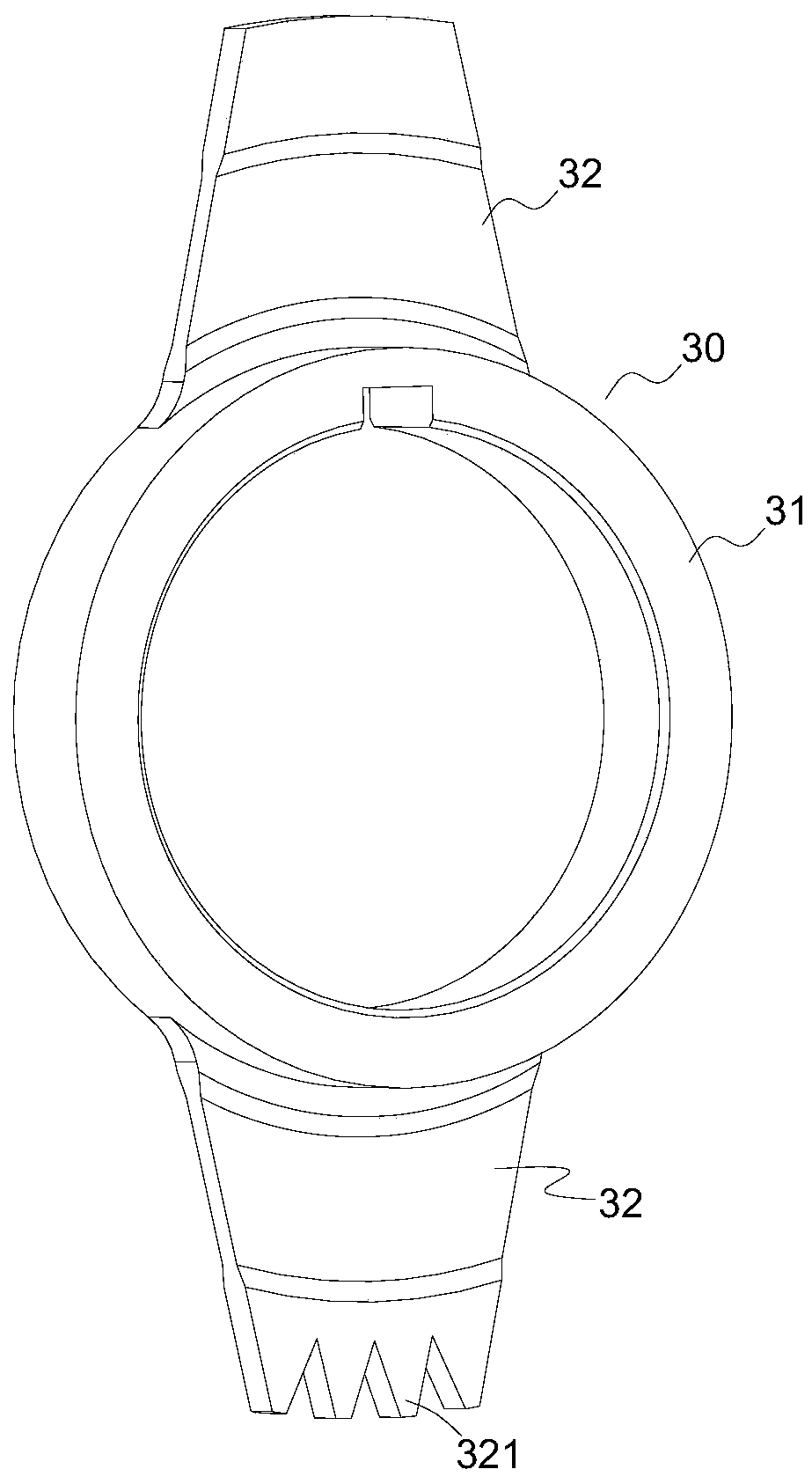

[0027] In order to better illustrate the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

[0028] At present, the lubrication structure of the vibrator is usually that an oil tank cover is arranged on the bearing assembly, and an oil chamber for containing lubricating oil is formed between the mailbox cover, the bearing seat and the bearing parts; in actual use, the oil chamber in the oil chamber The liquid level of the lubricating oil needs to be higher than the connection between the bearing seat and the bearing, or even higher than the connection between the main shaft assembly and the bearing, otherwise there is no lubrication or only a small amount of lubrication between the main shaft assembly and the bearing; therefore, the oil tank cover The connection with the main shaft assembly and the bearing seat needs to be provided with a complicated sealing method, which is usually a grease lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com