Method, system and equipment for acquiring pole piece quality information

A technology of quality information and acquisition method, applied in the field of pole piece quality information acquisition, can solve problems such as inability to evaluate the coating quality of a single small roll, inaccurate correspondence between cell capacity and coating weight, and inaccurate product information traceability. To achieve the effect of reducing workload and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

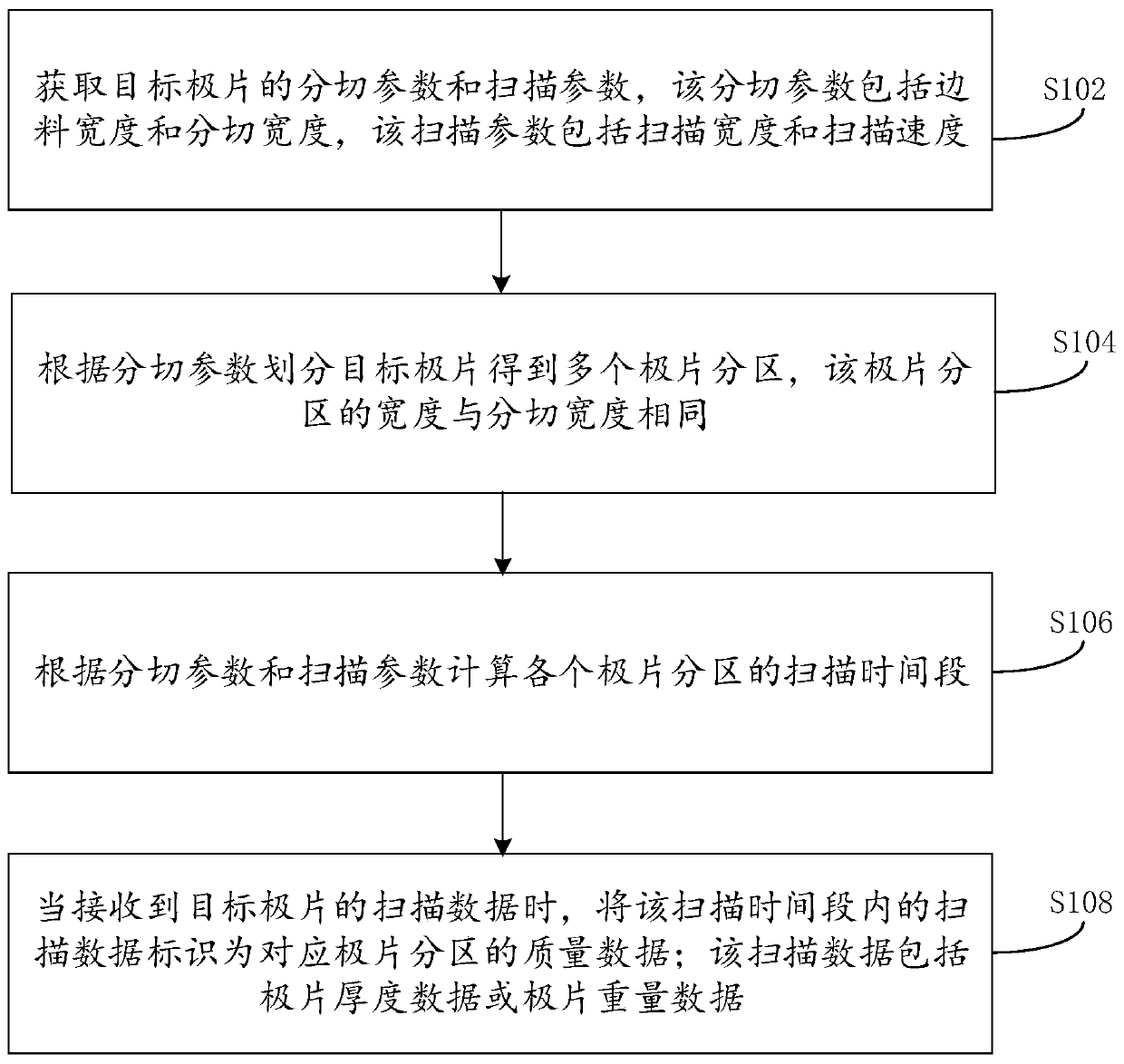

[0038] Such as figure 1 As shown, it is a schematic flow chart of a method for obtaining pole piece quality information provided by an embodiment of the present invention, which consists of figure 1 It can be seen that the method for obtaining pole piece quality information includes the following steps:

[0039] Step S102: Obtain the cutting parameters and scanning parameters of the target pole piece, the cutting parameters include trim width and cutting width, and the scanning parameters include scanning width and scanning speed.

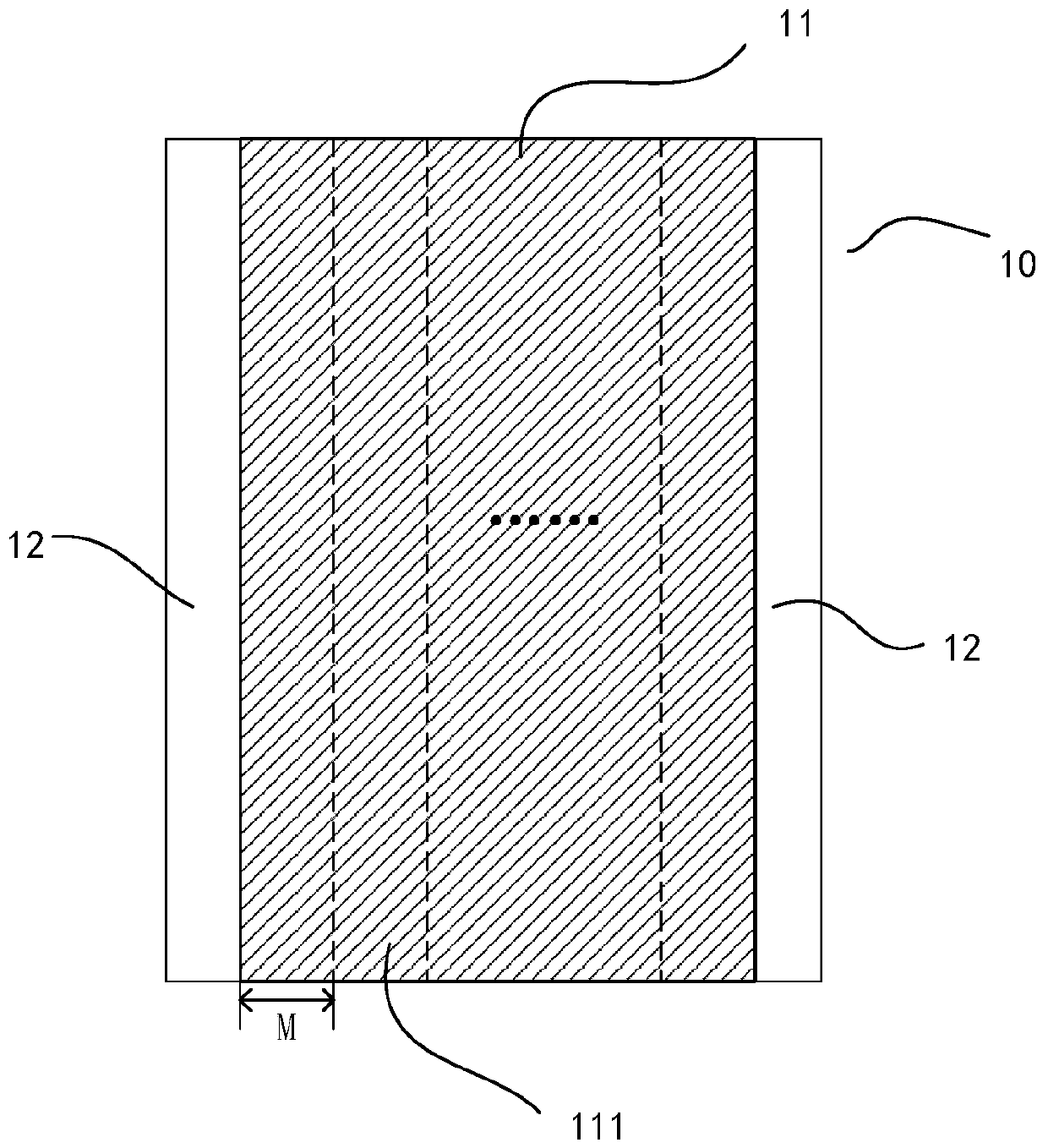

[0040] Here, the target pole piece will be cut into multiple small rolls according to the slitting parameters in the post-production process of the winding core. The width of the small roll is the slitting width. Outside the area is the side material. During the small roll production process, the side material part is cut out from the pole piece according to the width of the side material.

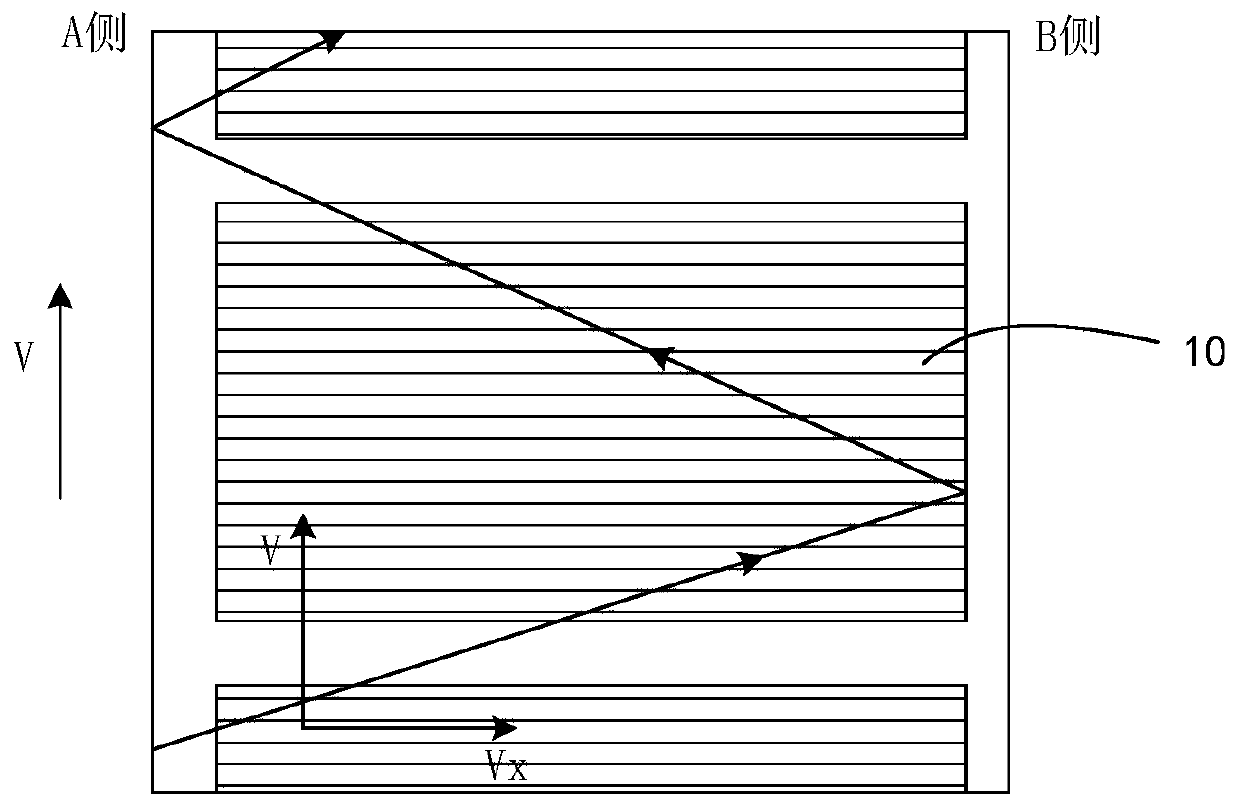

[0041] Scan the target pole piece according to the scan...

Embodiment 2

[0059] exist figure 1 On the basis of the pole piece quality information acquisition method shown, this embodiment provides another pole piece quality information acquisition method, such as Figure 4 As shown, the steps of the method include:

[0060] Step S402: Calculate the quality assessment parameters corresponding to the pole piece zone according to the quality data of the pole piece zone, and the quality assessment parameters include at least one of Mean, coefficient of variation Cov, process capability index Cp, and process comprehensive capability coefficient Cpk.

[0061] After obtaining the quality data corresponding to each pole piece partition, the quality evaluation parameters of each pole piece partition can be calculated according to the quality data, wherein the quality assessment parameters include mean (Mean), coefficient of variation (coefficient ofvariation, Cov), At least one of process capability index (Process Capability, Cp) and process comprehensive ...

Embodiment 3

[0068] In order to improve the utilization rate of the coating information of a single pole piece partition and facilitate the traceability of cell information, in Figure 4 On the basis of the pole piece quality information acquisition method shown, the embodiment of the present invention also provides another pole piece quality information acquisition method. Among them, the method includes:

[0069]Step 30, acquiring the cutting parameters and scanning parameters of the target pole piece, the cutting parameters include the trim width and the cutting width, the scanning parameters include the scanning width and the scanning speed.

[0070] Step 31 , divide the target pole piece according to the cutting parameters to obtain multiple pole piece partitions, and the width of the pole piece partitions is the same as the cutting width.

[0071] Step 32, generating codes for each pole piece partition, the codes are in one-to-one correspondence with the pole piece partitions. Here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com