Application of a Multifunctional Organogel in Sensors

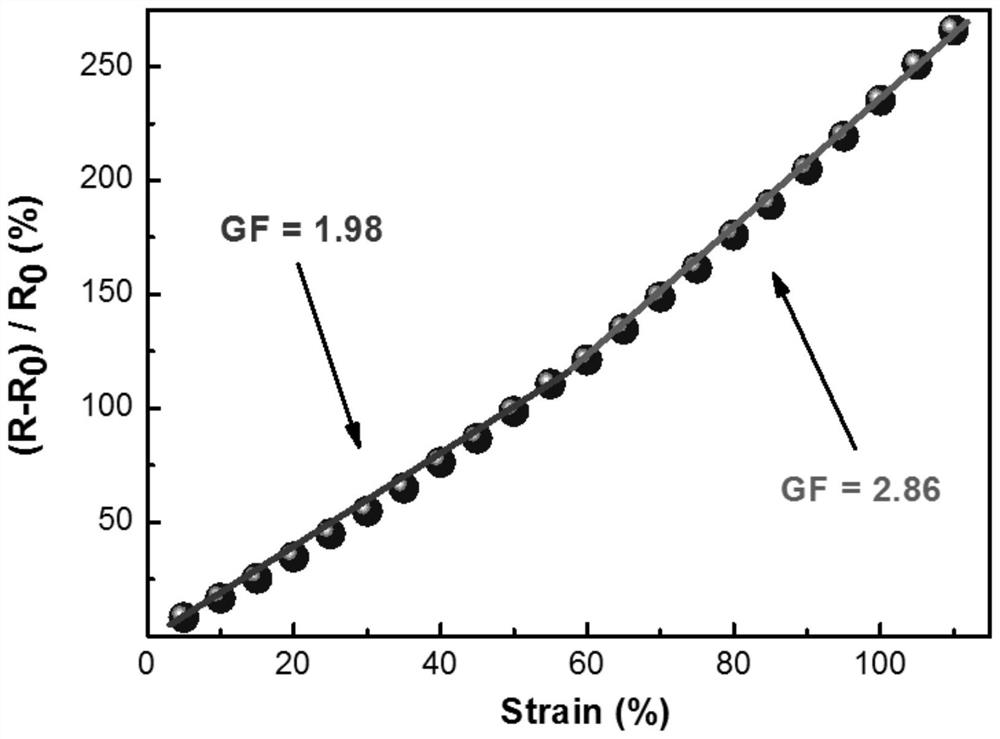

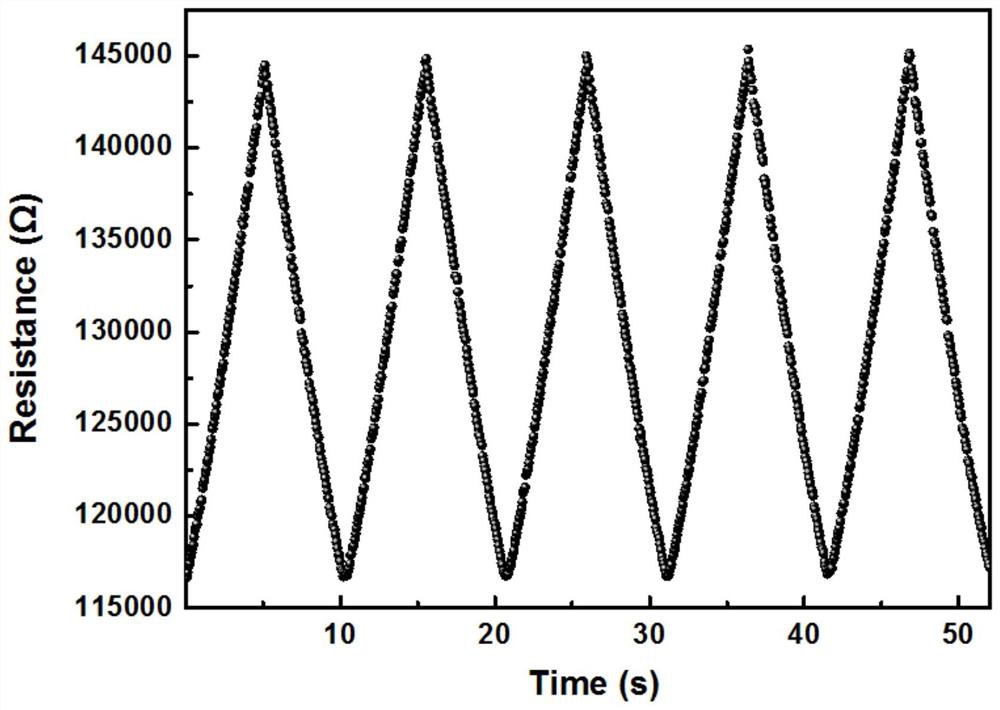

An organogel, multi-functional technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of unsuitable sensor manufacturing, poor air stability, short service life, etc., and achieve good chemical stability and good stretchability. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The raw materials of the multifunctional gel of the present embodiment include: 15ml of propylene carbonate, 5ml of N-acryloylmorpholine, 0.081g of 1-hydroxycyclohexyl phenone, 0.024g of polyethylene glycol diacrylate and 2.87 g Lithium bistrifluoromethylsulfonyl imide.

[0050] This embodiment includes the following steps:

[0051] The first step: measure 15ml of propylene carbonate and 5ml of N-acryloylmorpholine into a 50ml beaker, then weigh 0.081g of 1-hydroxycyclohexyl phenone and 0.024g of polyethylene glycol diacrylate, Finally, 2.87 g of lithium bistrifluoromethanesulfonimide (LiTFSI) was weighed and added to the beaker, and the solution in the beaker was ultrasonically dispersed for 20 minutes to completely dissolve the solid.

[0052] The second step: pour the solution prepared in the first step into a transparent sheet mold, and then place the sheet mold under a UV lamp with a wavelength of 365nm and a power of 400W to irradiate it for 10 minutes to cure it...

Embodiment 2

[0055] The raw materials of the multifunctional gel of the present embodiment include: 15ml of propylene carbonate, 5ml of N-acryloylmorpholine, 0.081g of 1-hydroxycyclohexyl phenone, 0.024g of polyethylene glycol diacrylate and 2.87 g Lithium bistrifluoromethylsulfonyl imide.

[0056] This embodiment includes the following steps:

[0057] The first step: measure 15ml of propylene carbonate and 5ml of N-acryloylmorpholine into a 50ml beaker, then weigh 0.081g of 1-hydroxycyclohexyl phenone and 0.024g of polyethylene glycol diacrylate, Finally, 2.87 g of lithium bistrifluoromethanesulfonimide (LiTFSI) was weighed and added to the beaker, and the solution in the beaker was ultrasonically dispersed for 20 minutes to completely dissolve the solid.

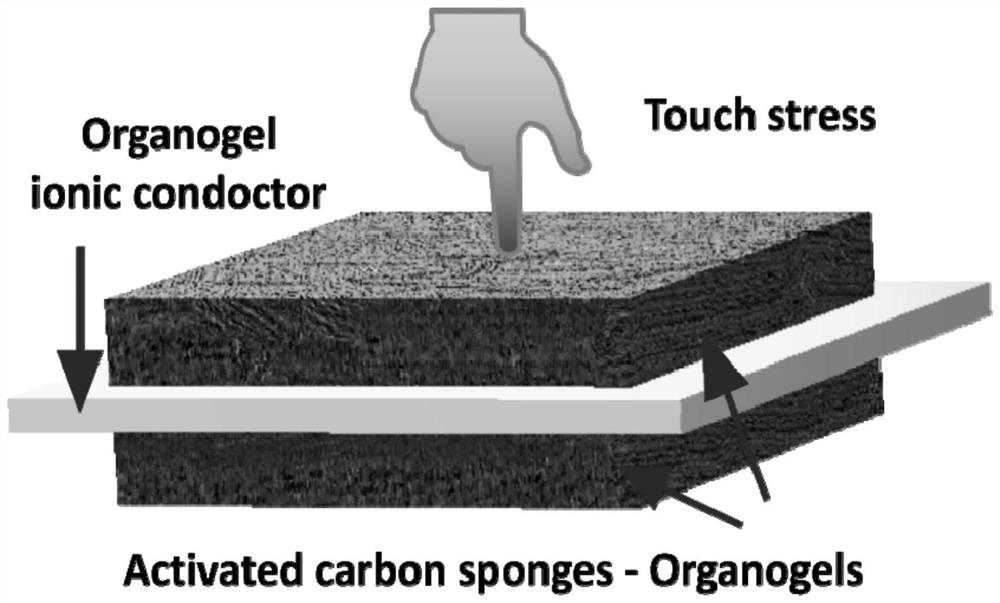

[0058] Step 2: Pour the solution prepared in the first step between two carbon sponges, and then place the carbon sponge under heating conditions (heating temperature 60°C, time 10h) to solidify the solution between the two carbon spo...

Embodiment 3

[0063] The raw materials of the multifunctional gel of the present embodiment include: 10ml of tributyl phosphate, 10ml of ethyl acrylate, 0.134g of 2-methyl-2-(4-morpholinyl)-1-[4-(methyl Thio)phenyl]-1-propanone, 0.024 g of polyethylene glycol diacrylate and 2.94 g of lithium 4,5-dicyano-2-trifluoromethylimidazolium (LiDTI).

[0064] This embodiment includes the following steps:

[0065] Step 1: Measure 10ml of tributyl phosphate and 10ml of ethyl acrylate into a 50ml beaker, then weigh 0.134g of 2-methyl-2-(4-morpholinyl)-1-[4-( Methylthio)phenyl]-1-propanone and 0.024g of polyethylene glycol diacrylate, and finally weighed 2.94g of 4,5-dicyano-2-trifluoromethylimidazolium lithium (LiDTI) into the beaker. The solution in the beaker was dispersed ultrasonically for 30 minutes to completely dissolve the solids.

[0066] The second step: pour the solution prepared in the first step into a transparent sheet mold, and then place the sheet mold under an ultraviolet lamp with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com