Coal blending combustion evaluation method and system

An evaluation method and technology for blending coal, which are applied in the field of evaluation methods and systems for blending coal blending, and can solve problems such as calculating combustion efficiency, boiler safety, and increasing auxiliary machine output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

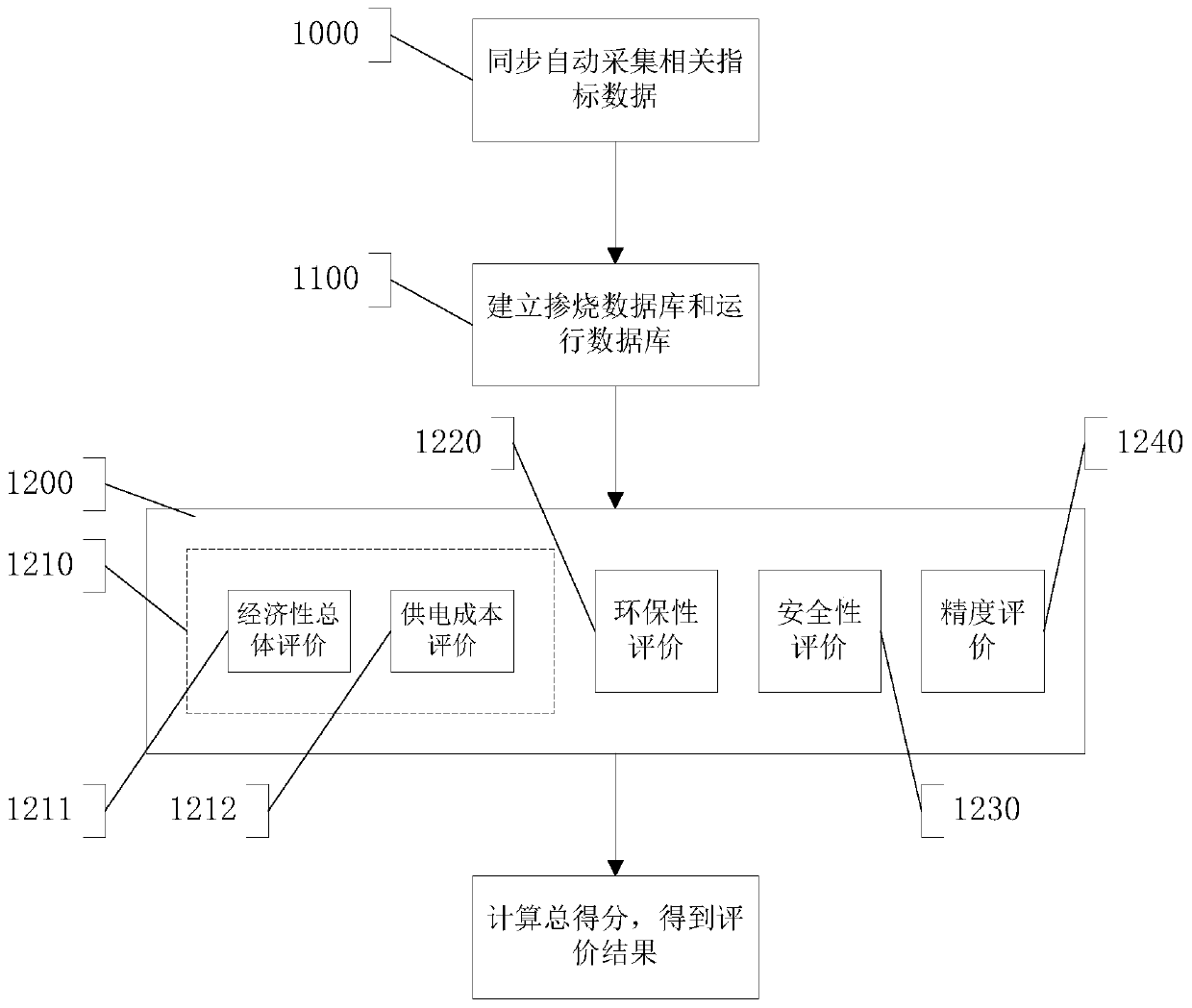

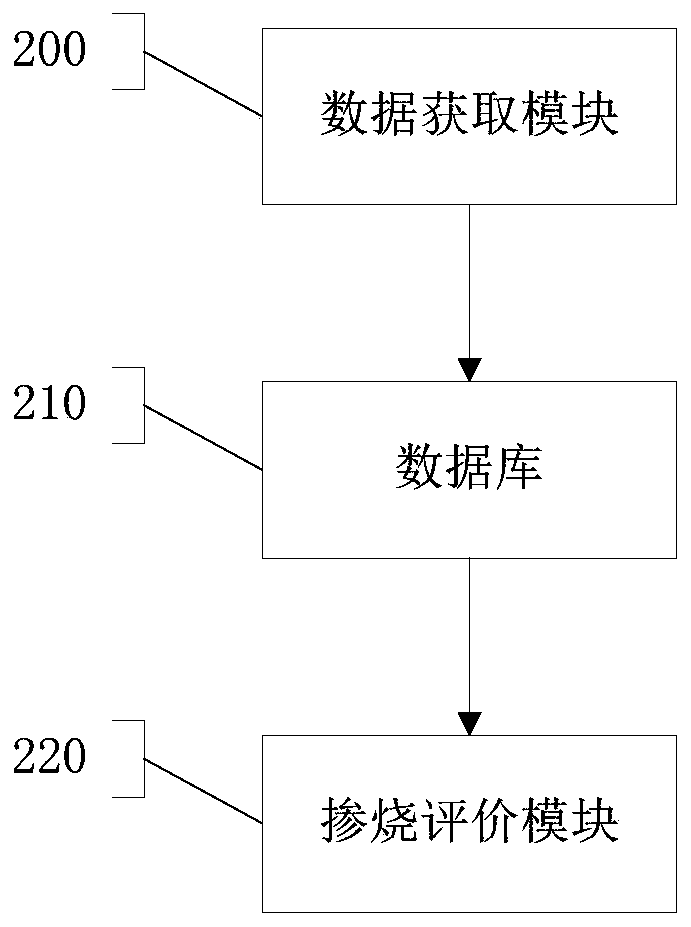

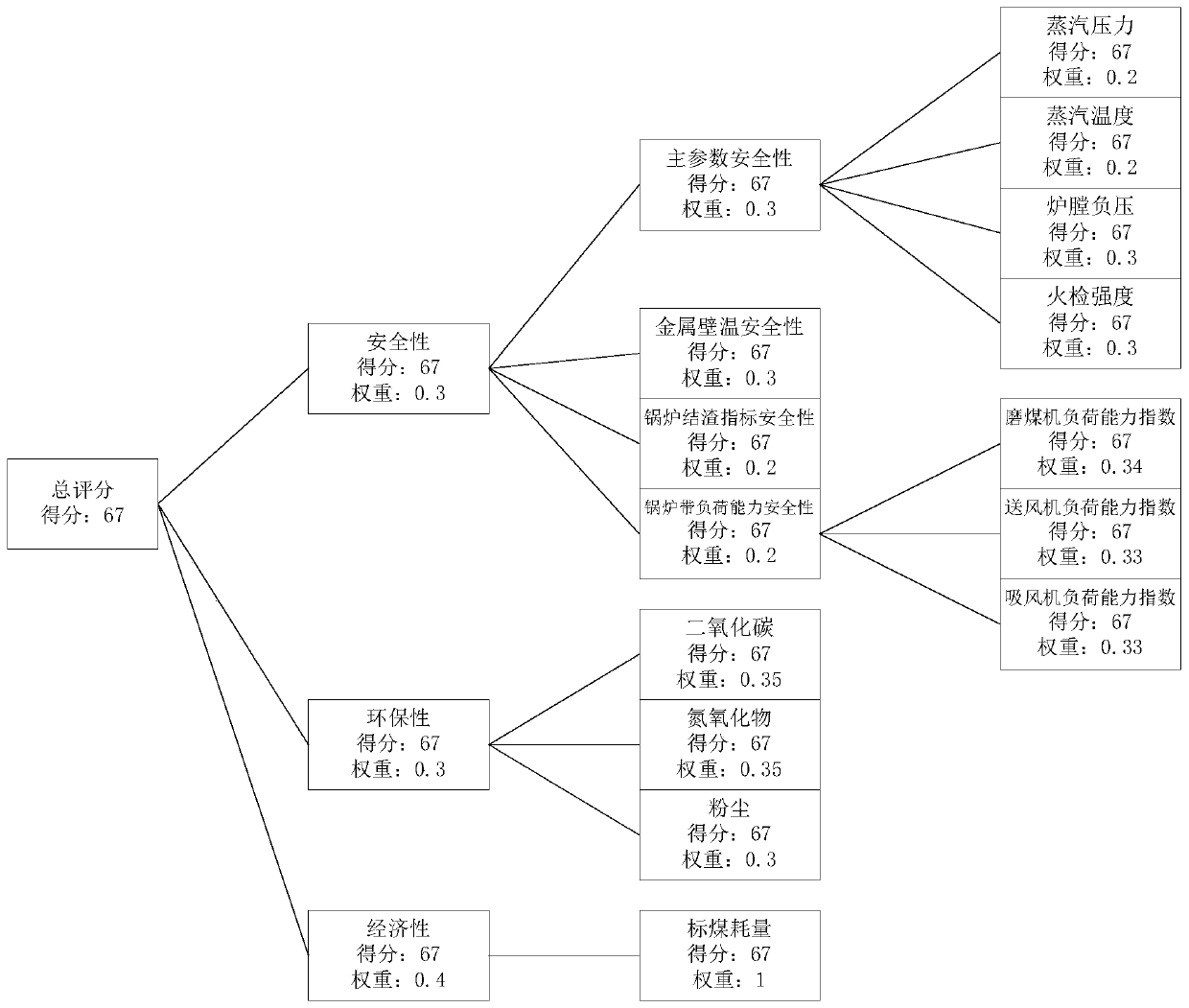

[0091] Such as figure 1 , 2 As shown, in step 1000, the data acquisition module 200 synchronously automatically collects relevant index data, and the relevant index data includes at least one of boiler combustion result data, various index data of coal entering the furnace, and power generation. The relevant index data can be divided into two categories, including at least one of the basic parameters and the effect parameters. Basic parameters are input parameters, which refer to parameters that have a decisive influence on the operation mode of the unit and the safe, economic and environmental protection operation of the unit. Once the basic parameters change, the unit operation mode must be adjusted accordingly to adapt to this change, generally including load , Coal type. Effect-type parameters, that is, output parameters, are parameters that characterize the performance of the unit. These parameters are not adjustable and are the response to the boiler combustion effect. ...

Embodiment 2

[0104] The system generates an evaluation analysis report based on the evaluation of the program and automatically collected relevant index data, which is convenient for providing optimization feedback suggestions for fuel management, and provides specific and targeted guidance.

[0105] The system synchronously collects SIS system data in real time, combines the real-time blending situation of the unit, and the combustion performance feedback data, establishes a database of blended combustion and operation, and uses the big data mining technology based on case library optimization to mine the conditions of the unit under different loads and different coal types. The best operating mode under.

[0106] Based on the coal bunker dynamic monitoring function described above, the system will automatically count the operating cycle of each coal type milled by each coal mill, and provide a reference for the regular change of coal types, such as high volatile coal types in one coal mill Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com