Winding machine of transformer

A technology for transformers and winding machines, which is applied in the manufacture of inductors/transformers/magnets, coils, electrical components, etc. It can solve the problems of large size of winding machines, unreasonable design of gluing device, cumbersome adjustment and operation of wire inlet device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

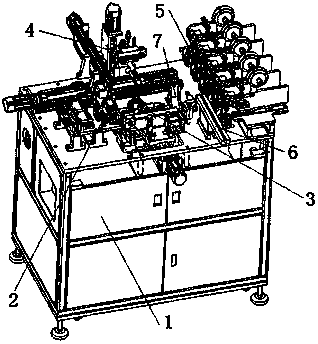

[0079] combine Figure 1~Figure 12 It can be seen that a winding machine for a transformer in the present invention includes a chassis 1, and the top of the chassis 1 is respectively provided with a threading sleeve device 2, a wire tube transmission turnover device 3, a transformer turnover feeding device 4, a glue application device 5, a transformer The feeding device 6 and the blanking track 7, the wire pipe transfer turnover device 3 is movably connected between the threading casing device 2 and the transformer turnover feeding device 4, and the transformer turnover feeding device 4 is movably connected to the transformer feeding device 6 , Between the line pipe transfer turnover device 3, the glue applicator 5 and the blanking track 7.

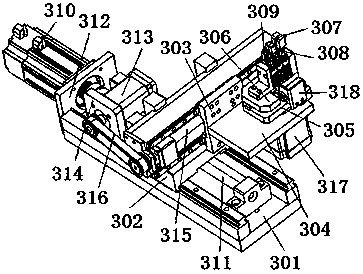

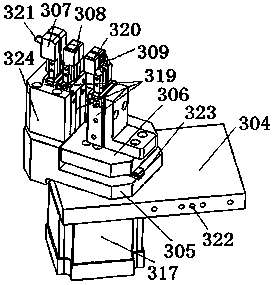

[0080] The wire tube conveying turnover device 3 includes a horizontal rail frame A301 fixed on the top of the cabinet 1, and the horizontal rail frame A301 is provided with a longitudinal rail frame A302 that moves horizontally along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com