Mechanism for raising and lowering vehicle window glass

A lifting mechanism and window glass technology, applied in vehicle parts, manual mechanisms, windshields, etc., can solve the problems of window glass tilting, encouragement, etc., and achieve the effect of preventing window glass from tilting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

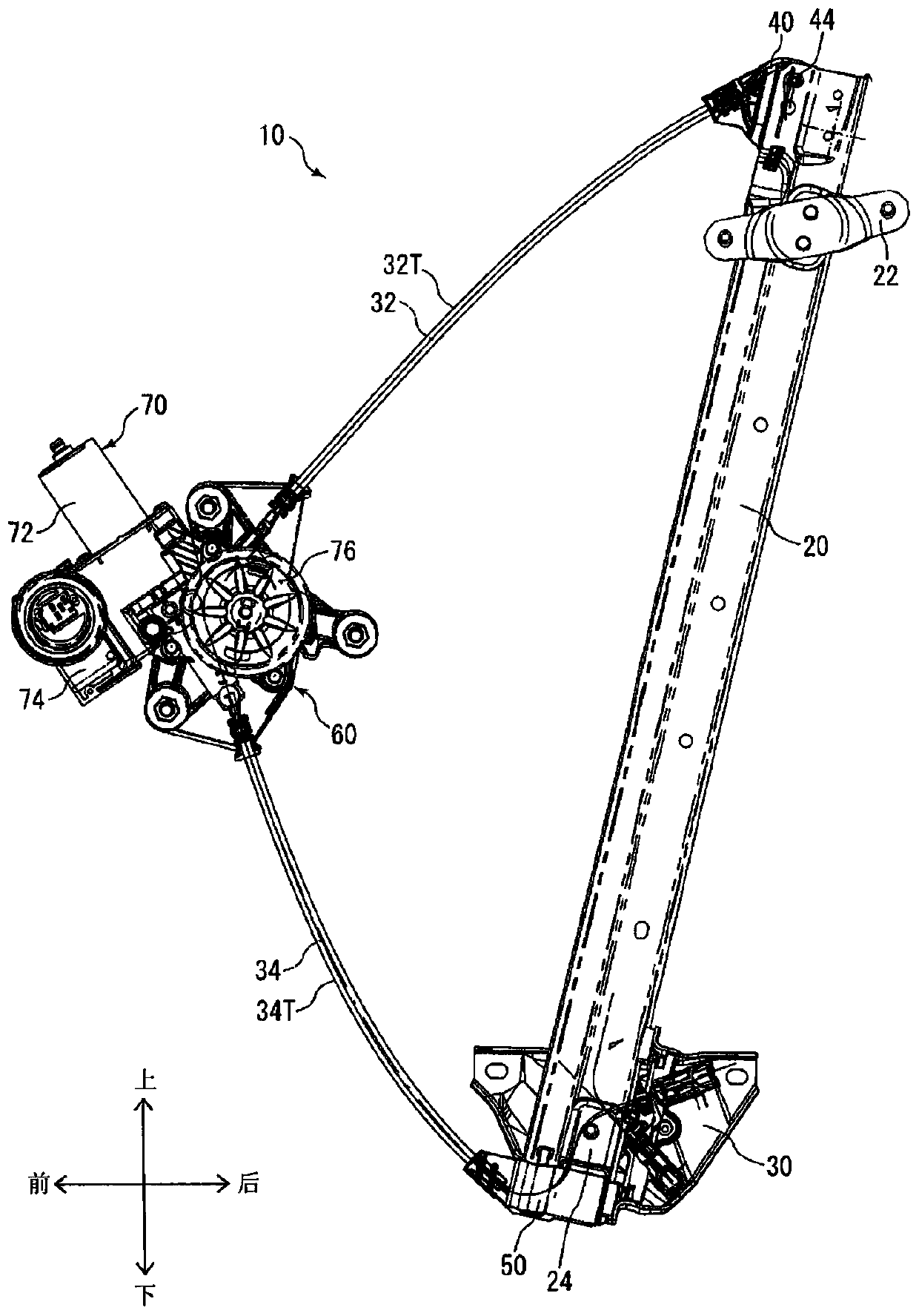

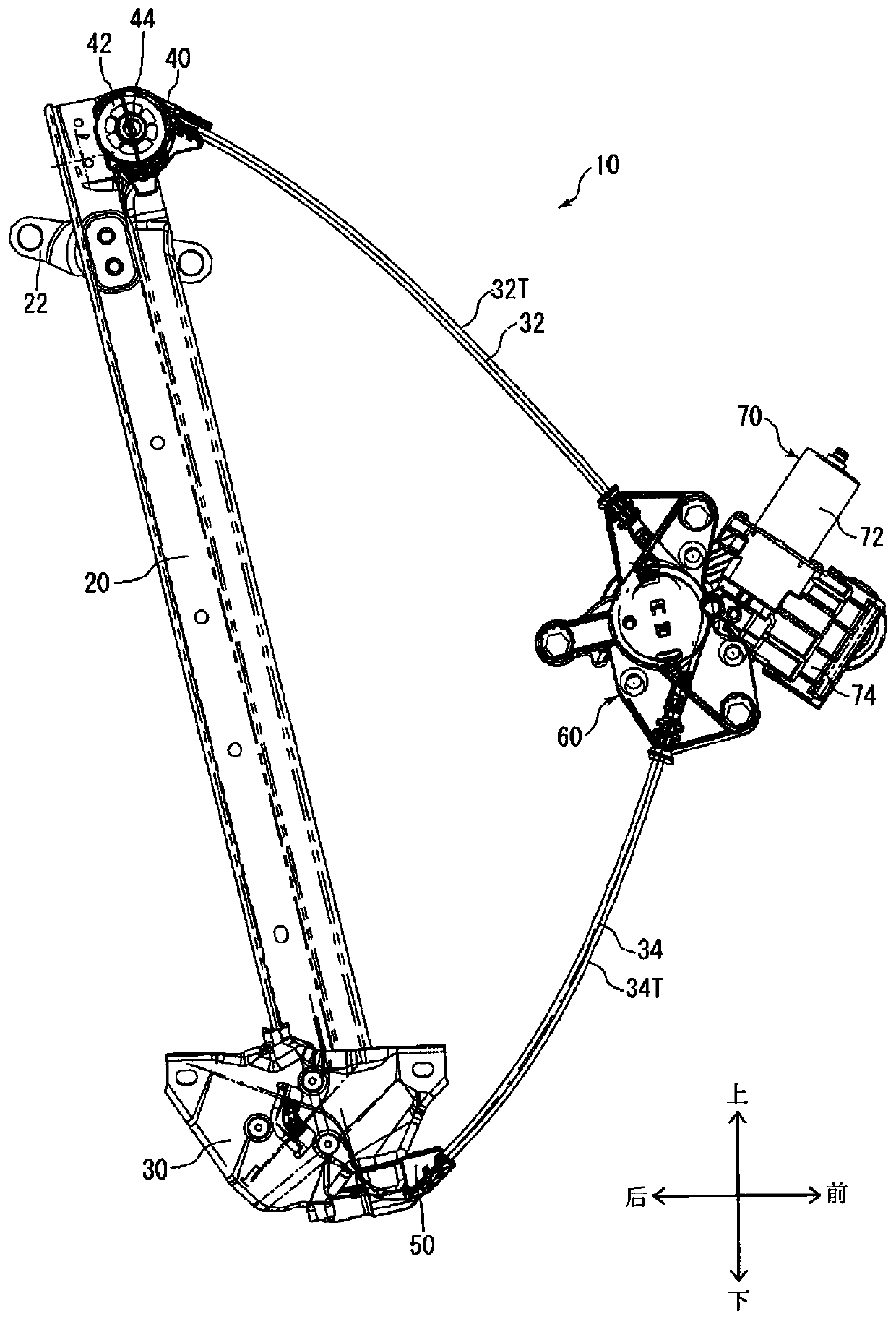

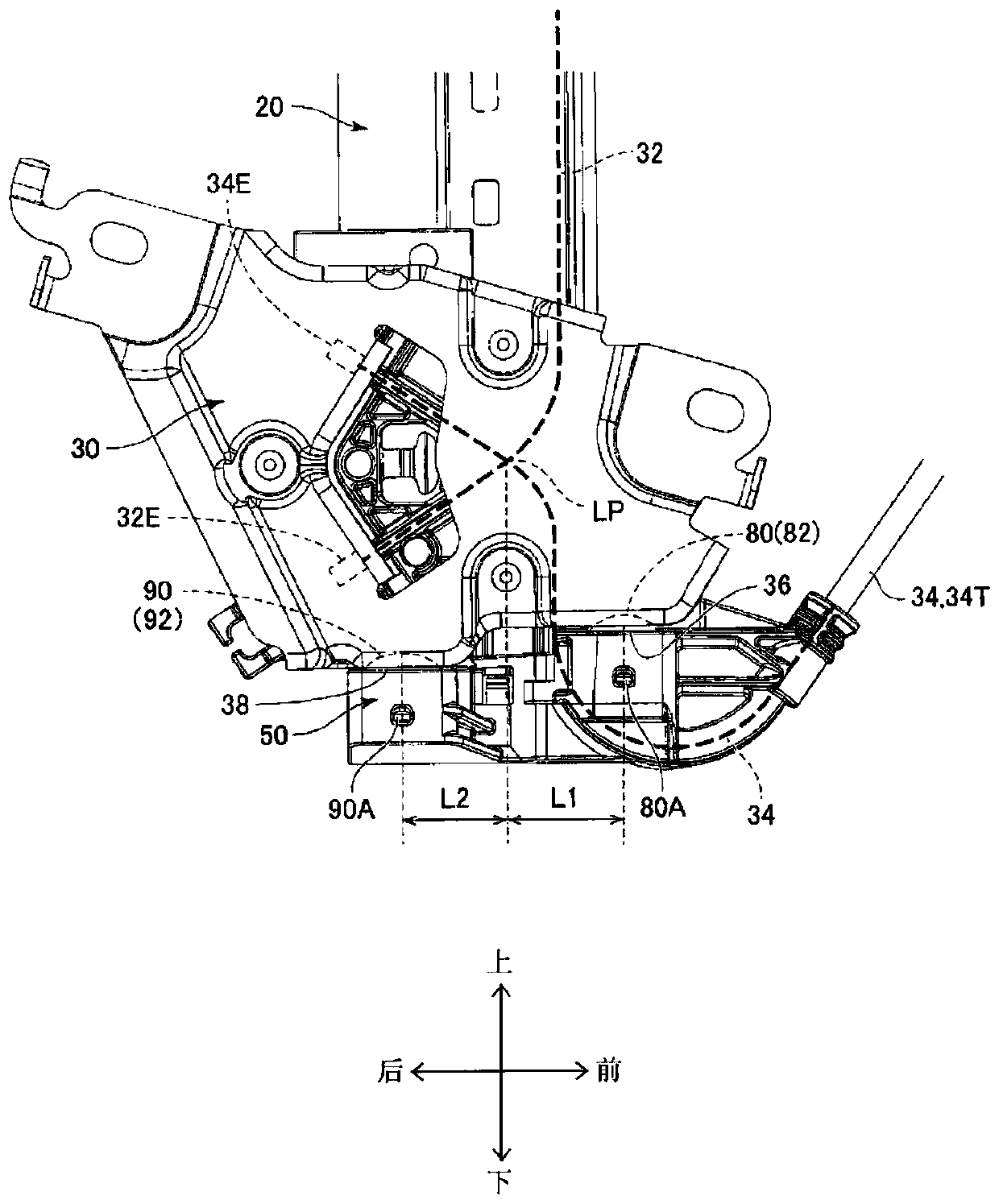

[0020] refer to Figure 1 to Figure 6 A vehicle window lift mechanism (window regulator) 10 according to the present embodiment will be described. The directions in the following description are based on the arrow-line directions described in the drawings. exist Figure 1 ~ Figure 2 and Figure 3 ~ Figure 6 Among them, the structure of the vehicle window lift mechanism 10 (in particular, the structure of the carrier plate 30 and the lower guide member 50) is different, but this is only for the convenience of drawing. Figure 1 ~ Figure 2 It is an orientation of a conceptual diagram showing the basic structure of the window glass lift mechanism 10 for a vehicle, and the characteristic parts of the window glass lift mechanism 10 for a vehicle according to this embodiment (the structure of the support plate 30 and the lower guide member 50, and the two The support structure near the bottom dead center (falling end) of the component) is expressed in Figure 3 ~ Figure 6 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com