Sticker attaching equipment for surface of solid wood door

A technology of solid wood doors and stickers, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of heavy workload of workers, achieve the effect of reducing workload, reducing friction, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

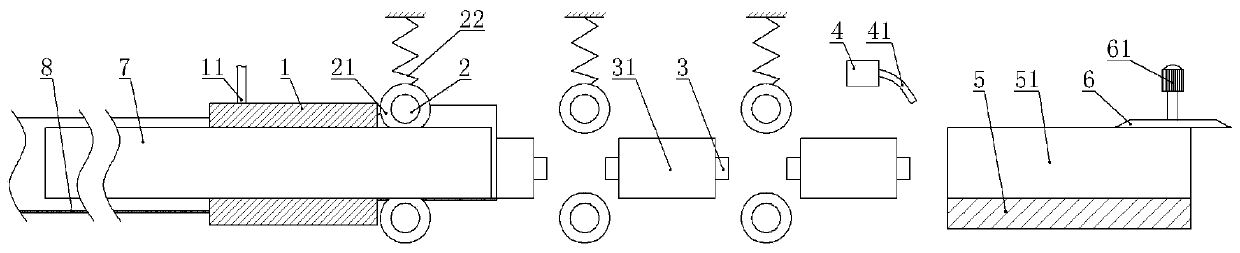

Embodiment 2

[0043] On the basis of Example 1, such as image 3 As shown, the right side of the extrusion mechanism in this embodiment is also provided with an air source 4 and a grinding and cutting mechanism in sequence from left to right. The air source 4 in this embodiment is a fan, and the air source 4 is fixed on the frame by bolts , the air source 4 is connected with an air outlet pipe 41, and when the door frame 7 with the sticker 8 on the surface passes through the air outlet pipe 41, the glue is dried by the air discharged from the air outlet pipe 41.

[0044] Grinding and cutting mechanism comprises support seat 5, and support seat 5 is provided with the support groove 51 that opening faces upwards, and the width of support groove 51 is greater than the width of door frame 7, and the height of support groove 51 bottoms and the first channel 12 bottom surface heights, support The height of the side wall of the groove 51 is the same as that of the door frame 7 , that is, when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com