Apparatus for additively manufacturing three-dimensional objects

A three-dimensional object and additive technology, applied in the direction of additive manufacturing, processing manufacturing, metal processing equipment, etc., can solve problems such as time-consuming and energy-incapable implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

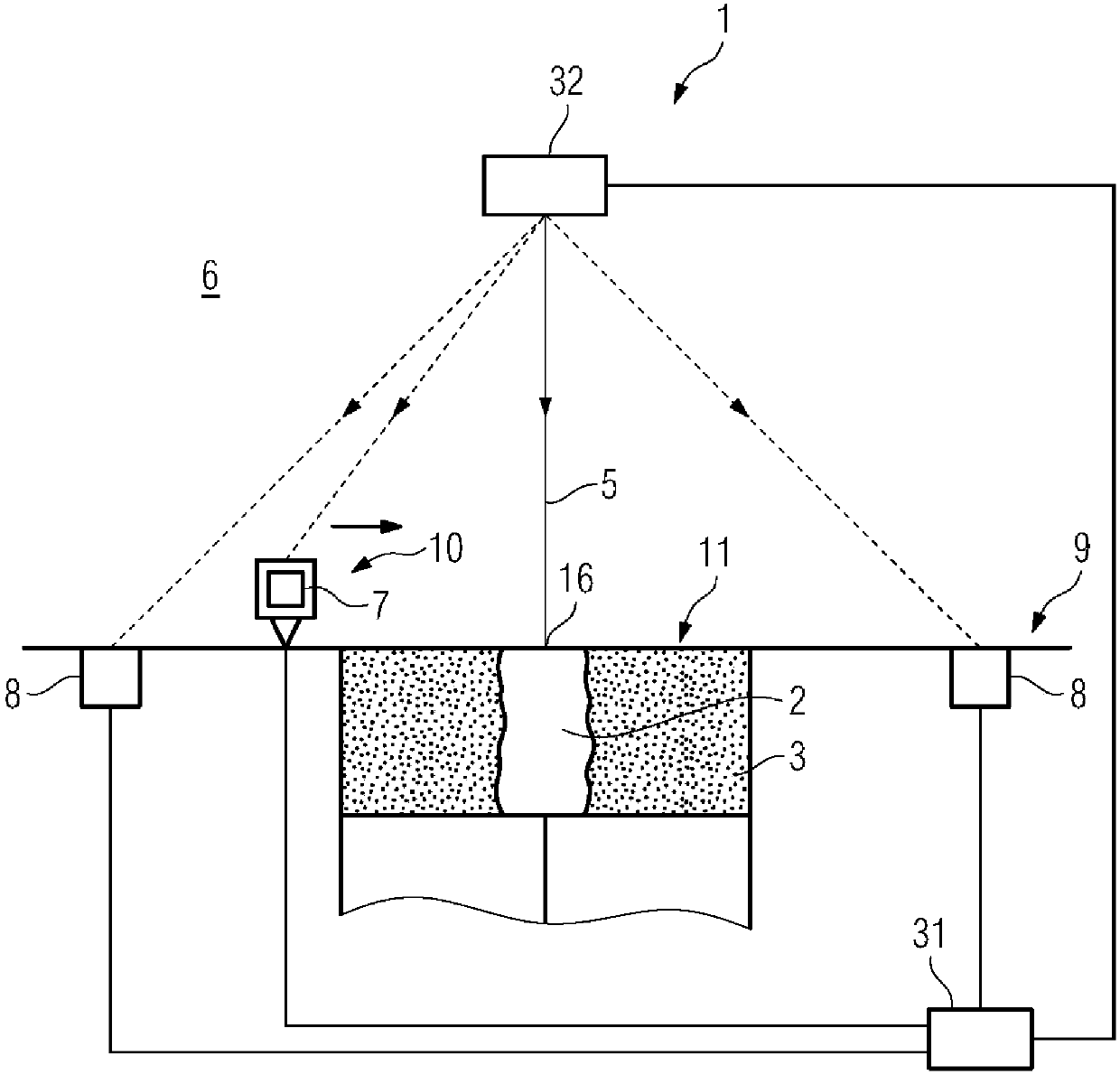

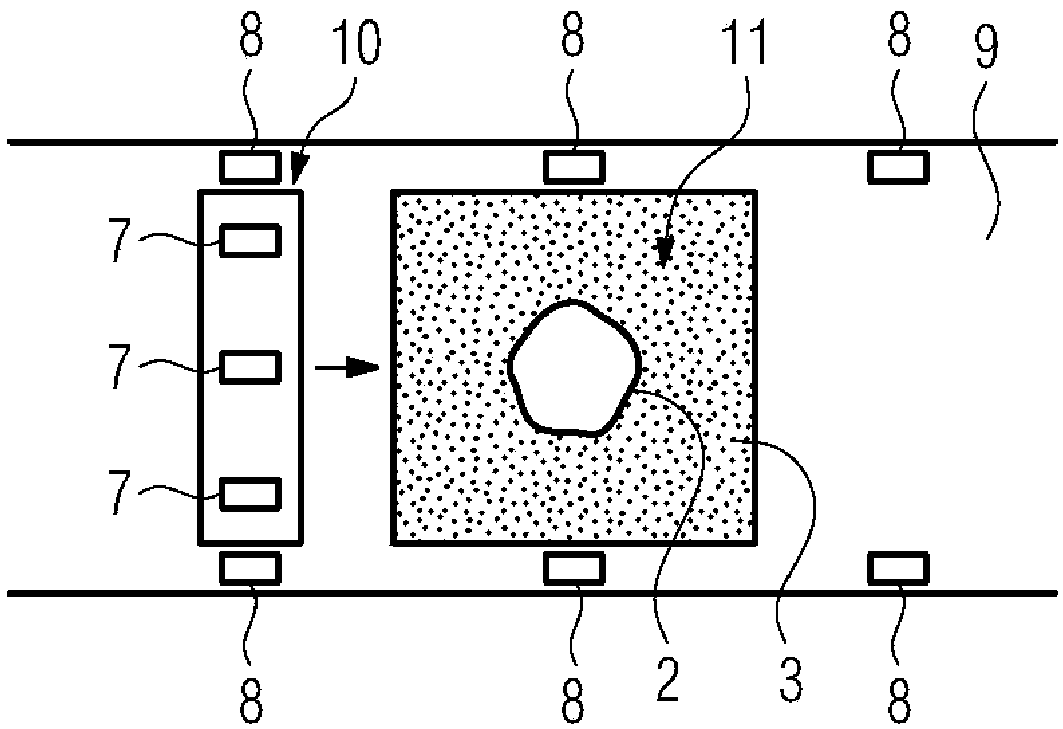

[0042] figure 1 A device for the additive production of a three-dimensional object 2 is shown by selectively irradiating and curing layers of a building material 3 which can be cured by means of an energy beam 5 guided into the interior of a process chamber 6 of the device 1 by selectively irradiating and curing them layer by layer in succession 1. The device 1 comprises determining means 7 , 8 adapted to determine at least one parameter of the energy beam 5 . Thus, an energy beam 5 can be generated and guided via the irradiation device 32 , in particular in such a way that the energy beam 5 is incident on the determination device 7 , 8 . The energy beam 5 incident on the respective determination device 7 , 8 is shown via dashed lines to emphasize that the energy beam 5 can be directed to the respective determination device 7 , 8 . as from figure 1 It follows that the determining devices 7 , 8 are arranged inside the process chamber 6 .

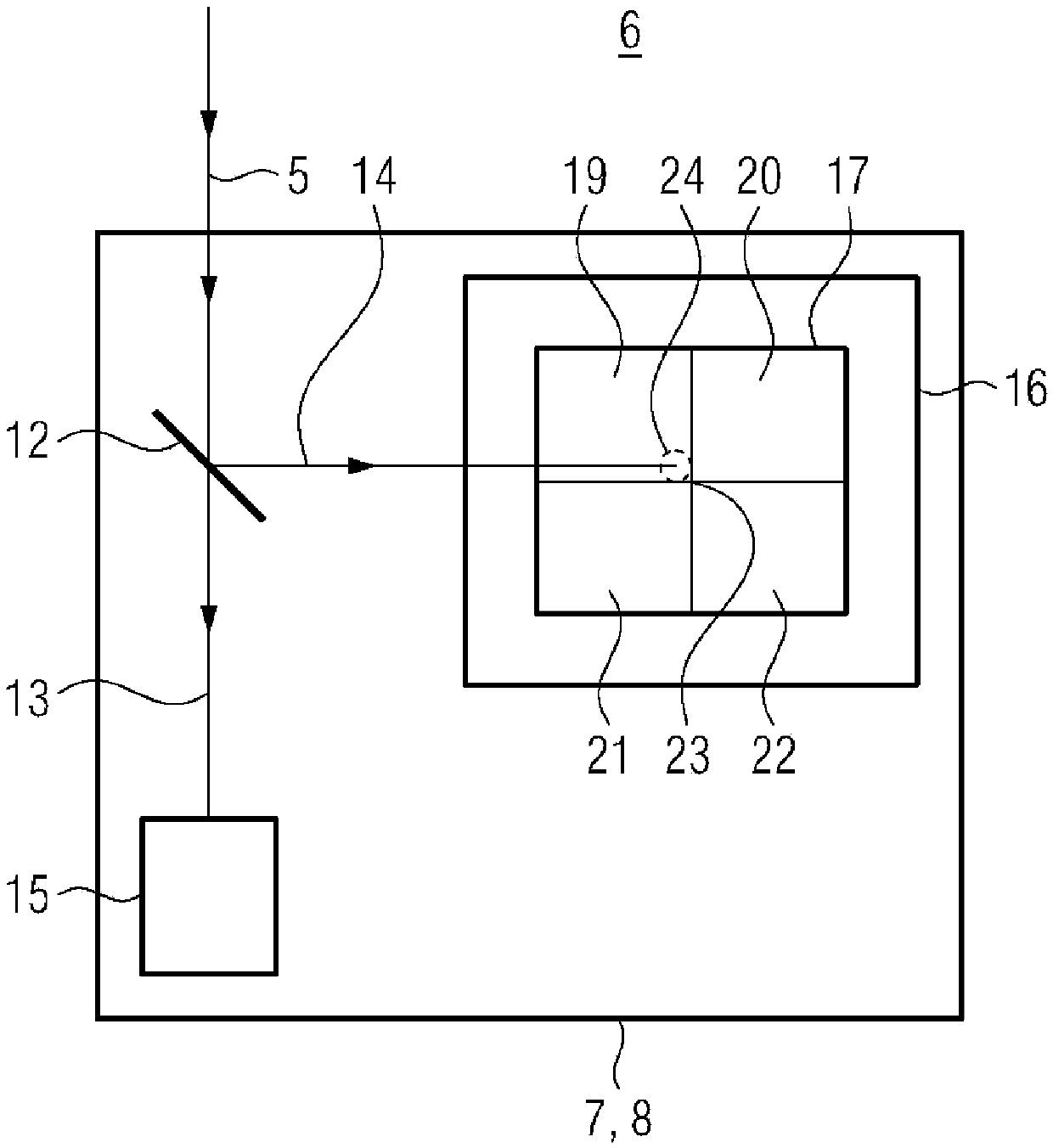

[0043] Determining device 7 ( fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com