An adaptive anti-swing shock device for dangerous goods storage vehicles

An impact device and storage vehicle technology, which is applied in the direction of freight vehicles, article transport vehicles, motor vehicles, etc., can solve the problems of destroying the structure of the tank body, endangering driving safety, and impacting anti-corrosion coatings, so as to improve driving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

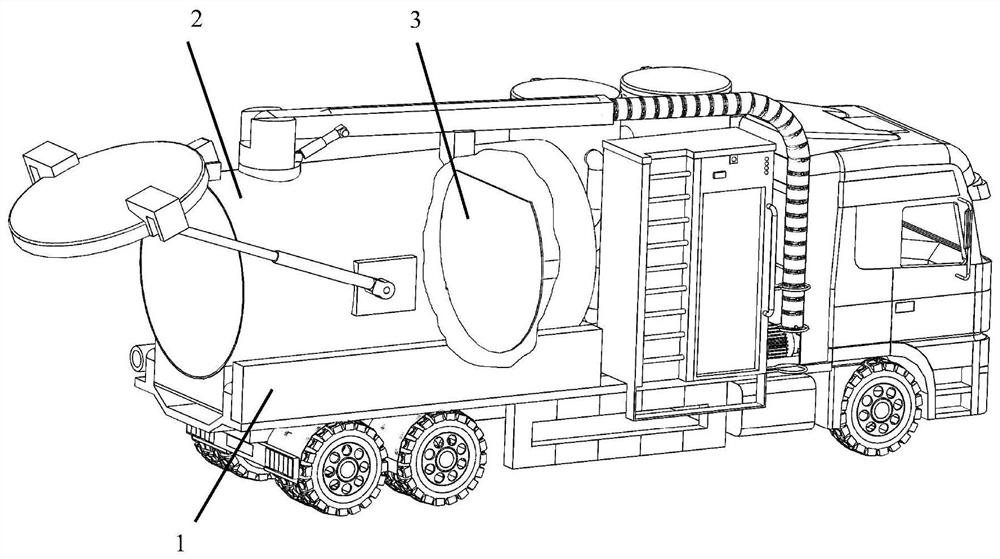

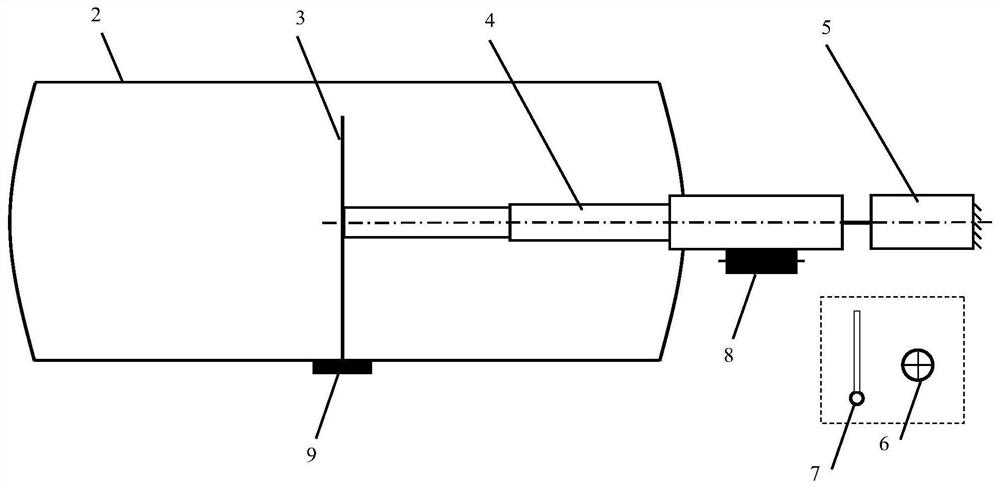

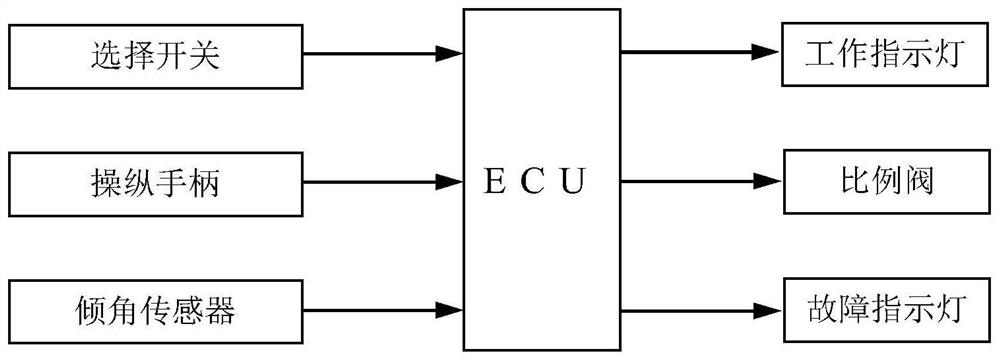

[0014] like Figure 1-Figure 3 As shown, in order to achieve the above purpose, the present invention proposes an adaptive anti-swing impact device for dangerous goods storage vehicles, which includes a discharge push plate 3, a multi-stage hydraulic cylinder 4, a joystick 7 and a selection switch 6 , the discharge push plate 3 is located in the inner cavity of the storage main tank 2, and the storage main tank 2 is placed on the chassis 1 of the dangerous goods storage vehicle, and the leaked dangerous goods are sucked and stored in the storage main tank 2 by vacuum negative pressure, and the storage main tank 2 is unloaded. The front end of the material push plate 3 is connected to the piston rod of the multi-stage hydraulic cylinder 4 arranged along the axial direction of the storage main tank 2. The cylinder body of the hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com