A kind of water jet cutting equipment with magnetic reinforcement for mining

A kind of cutting equipment and reinforced technology, which is applied in the direction of metal processing equipment, used abrasive processing devices, explosion generating devices, etc., can solve the problem of not being able to automatically adjust the cutting angle of the cutting nozzle and automatically change the cutting nozzle, and cannot guarantee the cutting nozzle Problems such as the target distance between the end nozzle and the anchor rod and the poor fixing effect of the clamping part can achieve the effect of increasing the anchor withdrawal efficiency, increasing the fixing effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

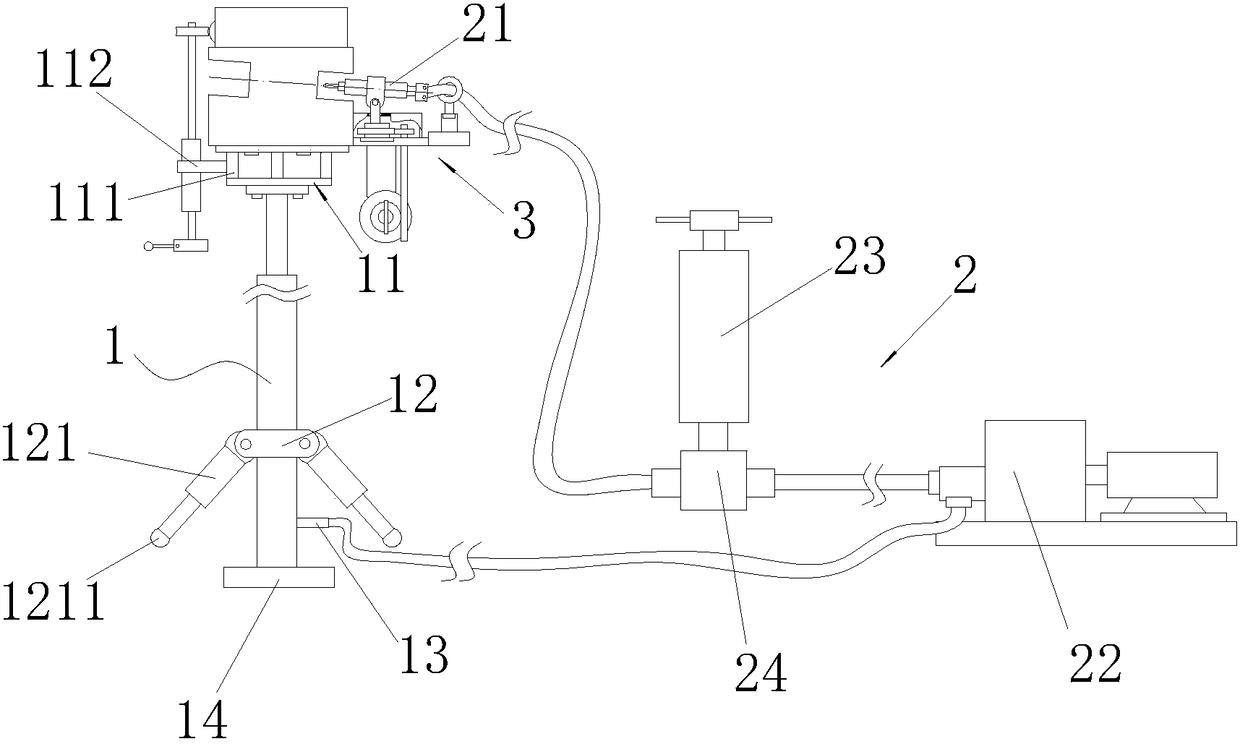

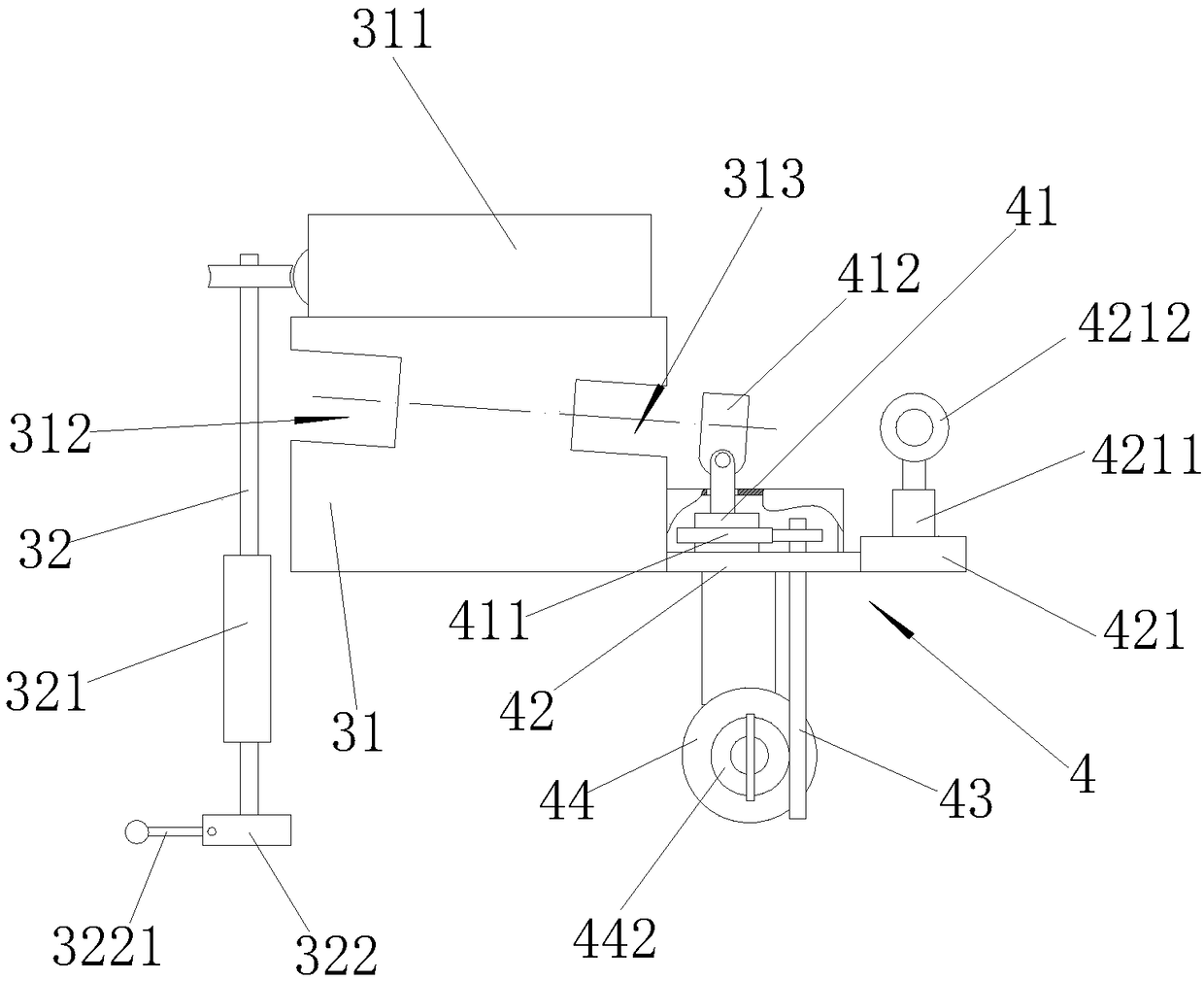

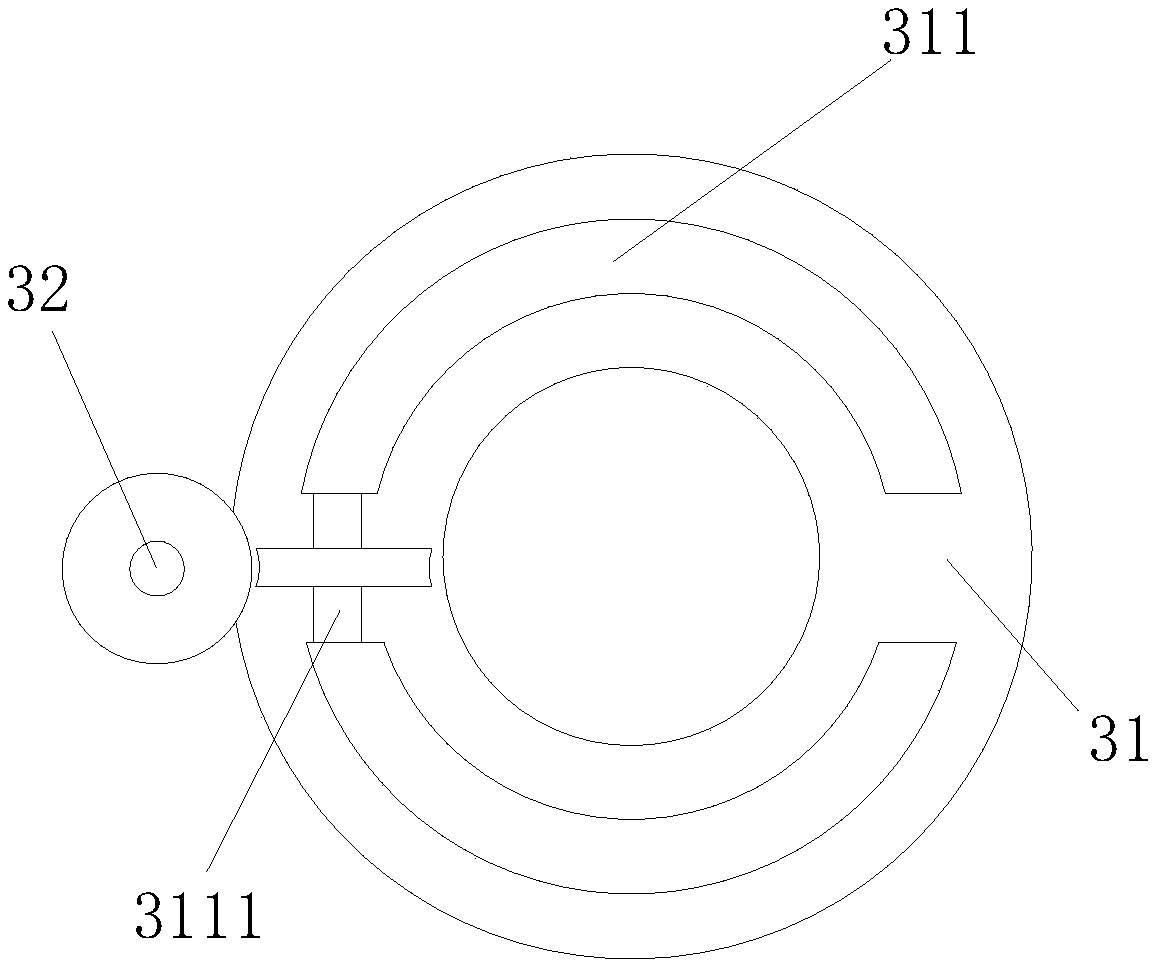

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the magnetically reinforced anchor-removing water jet cutting equipment for mining includes a single hydraulic prop 1 and an abrasive jet launching device 2, and also includes an anchor-removing device 3, and the anchor-removing device 3 includes an annular cylinder seat 31 And the opening and closing magnetic threaded rod 32, the upper end of the annular cylinder seat 31 is symmetrically equipped with a semi-annular magnetic box 311, and the left end of the semi-annular magnetic box 311 is equipped with a driving rod 3111, and the driving rod 3111 is connected to the opening and closing by a bevel gear. The bevel gears on the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com