A Highly Reliable Displacement Classification Mechanism for Pumps

A reliable and pump technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of complex system structure, reliability impact, product status control and maintenance workload, etc. Reliability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

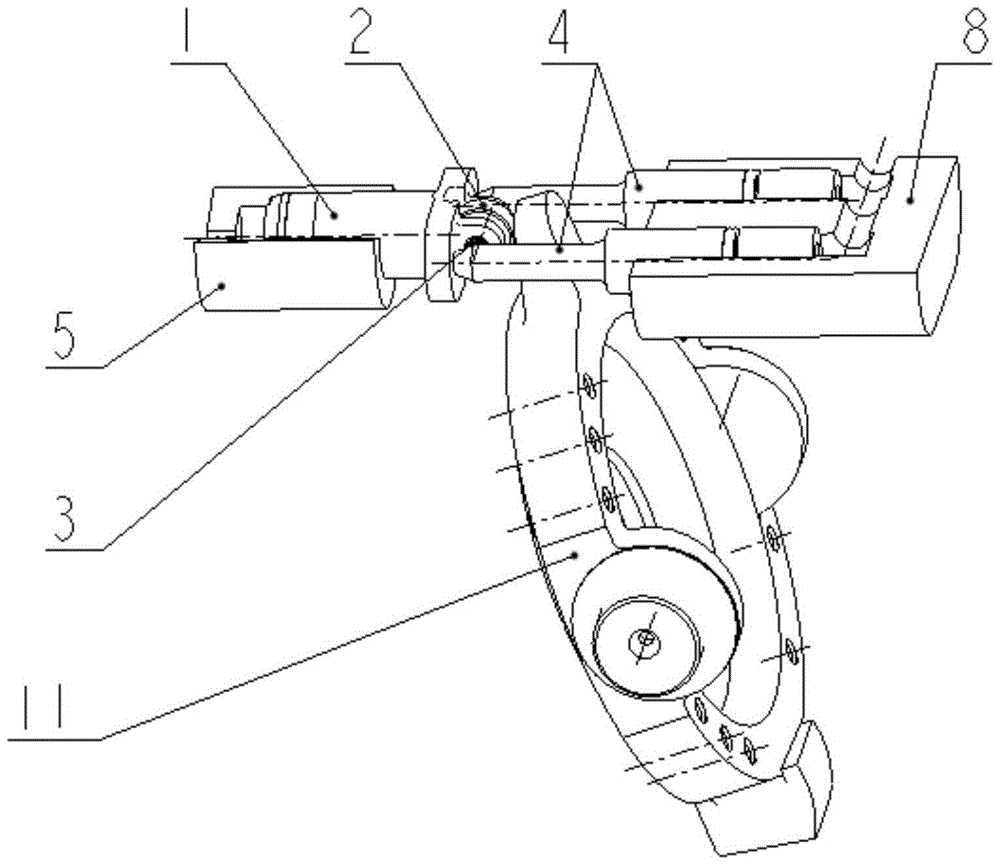

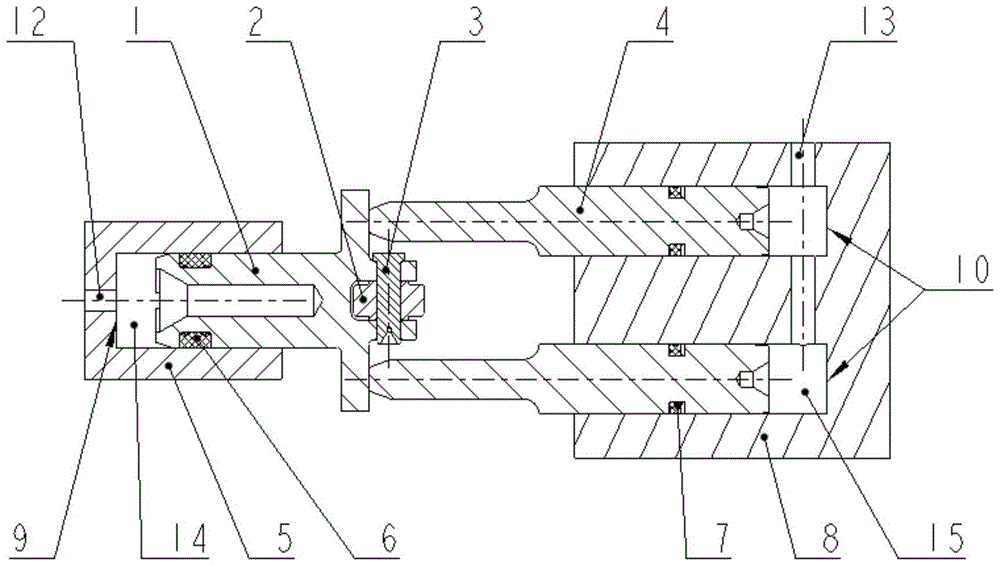

[0019] Such as figure 1 and 2 As shown, a high-reliability displacement gearing mechanism for a pump includes a piston 1, a roller 2, a pin 3, a push rod 4, a piston seat 5, a piston seal 6, a push rod seal 7, a push rod seat 8 and a pendulum Frame 11, two push rods 4 are symmetrically arranged on both sides of the large-diameter end face of piston 1 in the axial direction of piston 1, roller 2 is installed in the roller groove in the middle of the large-diameter end of piston 1, the material of roller 2 is bearing steel, pin 3 Through the center hole of the roller groove of the roller 2 and the piston 1, the material of the pin 3 is high-strength stainless steel, the roller 2 rests on the lug position of the swing frame 11, the piston 1 forms a piston chamber 14 in the piston seat 5, and the high-pressure oil flows from the piston The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com