Distribution barrel overturning device

A technology for turning barrels and barrel walls is applied in the field of automation of weaving dye factories, which can solve the problems of reducing work efficiency, multi-manpower, consumption, etc., and achieve the effects of improving controllability, improving flexibility, and improving automation and work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

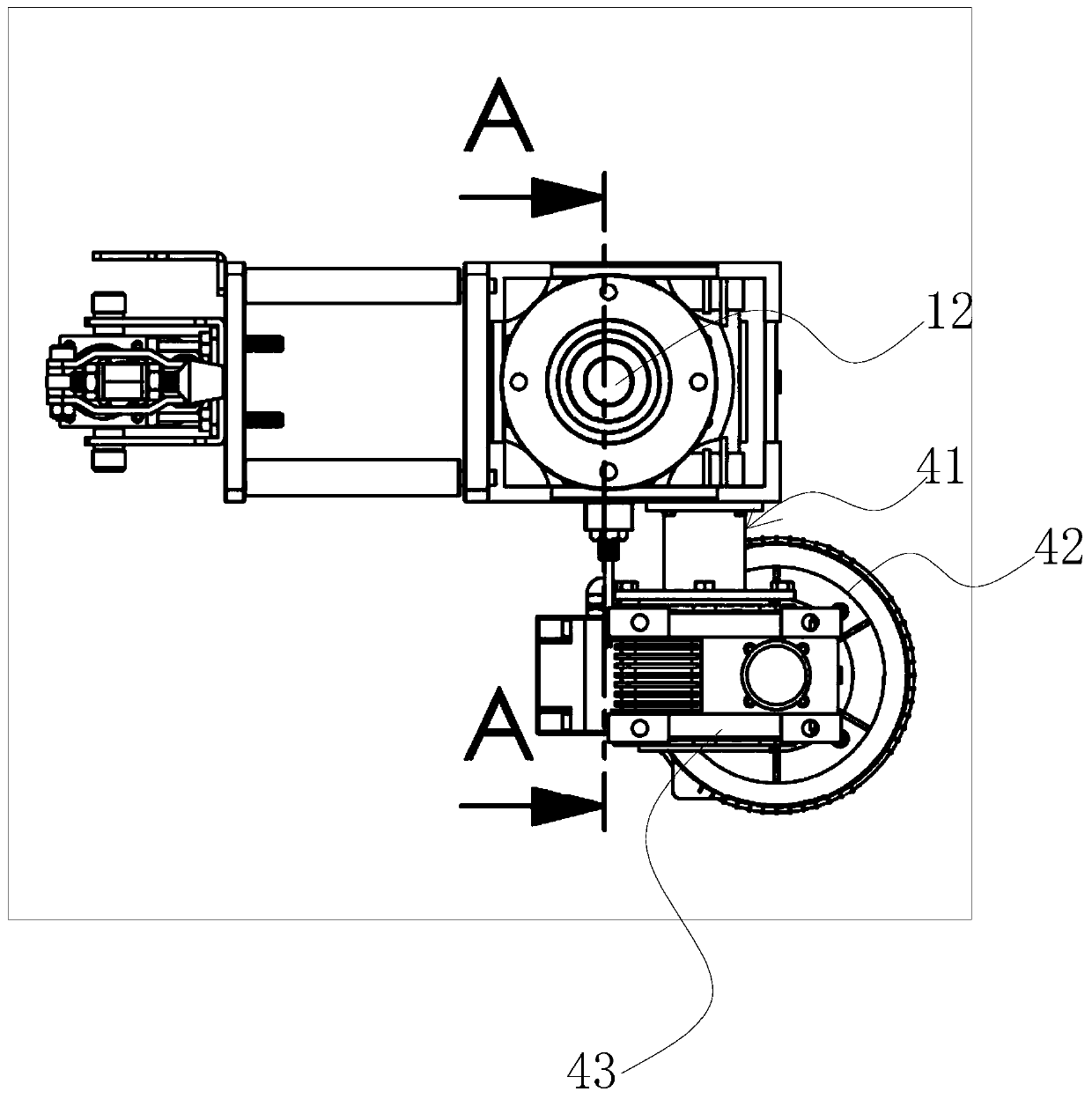

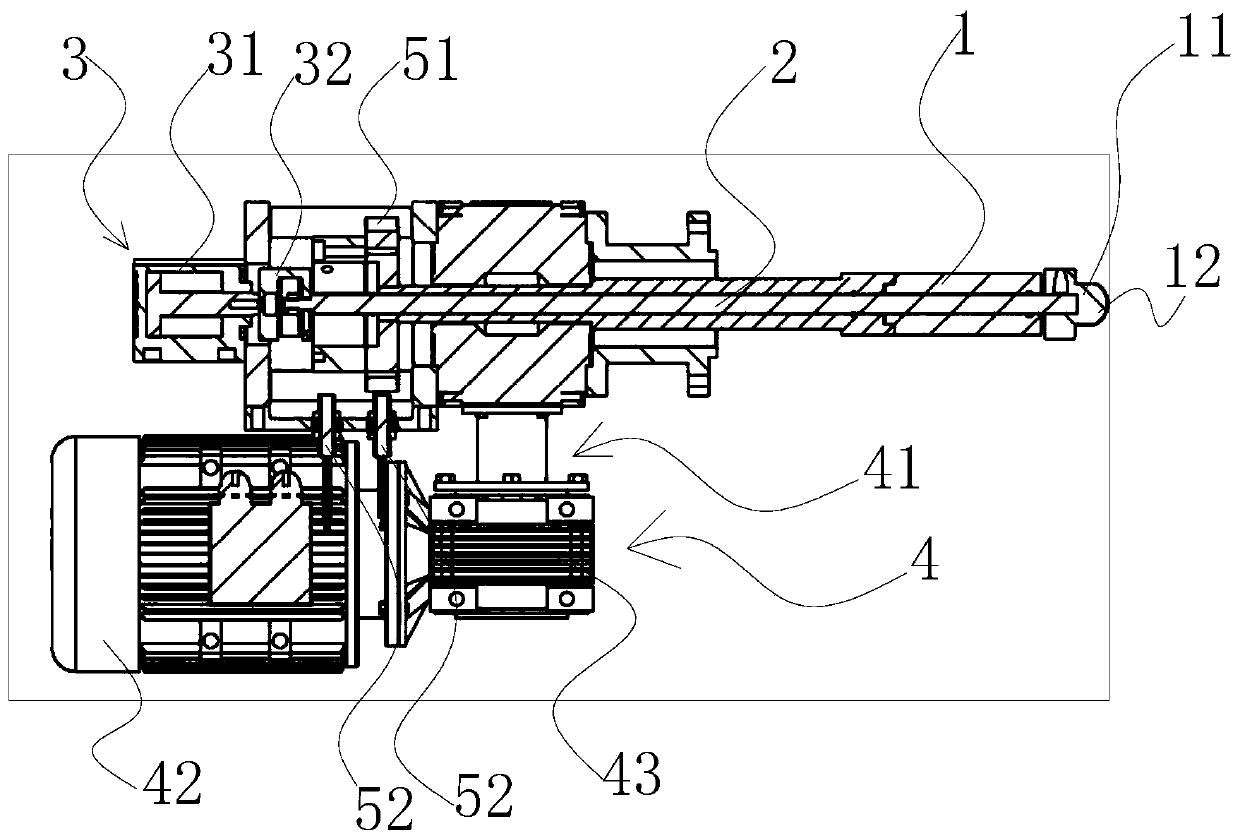

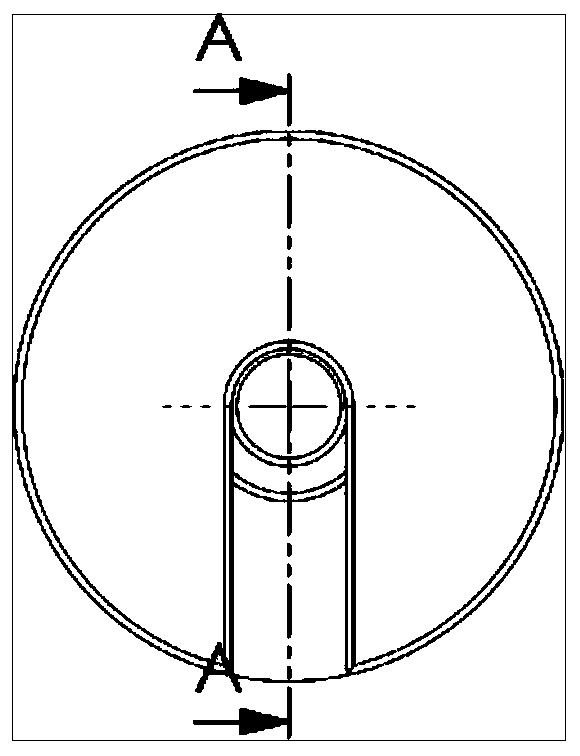

[0028] Such as figure 1 and figure 2 As shown, the present embodiment has opened a kind of delivery bucket turning device, comprises the first bucket turning structure, and the first bucket turning structure comprises a barrel pressure bar 1 with a keg wall contact portion 11 at one end, and the keg wall contact portion 11 is used In order to connect the outer wall of the keg, the end of the barrel pressing rod 1 away from the contact portion 11 of the keg wall has a turning bar 2, the turning bar 2 and the pressing bar 1 can be set as one body or can be a split structure and connected to each other. The end of the barrel rod 2 far away from the barrel pressing rod 1 is connected with a telescopic control mechanism 3 for the telescopic barrel turning lever 2 and a rotation control mechanism 4 for circumferentially rotating the barrel turning lever 2, and the telescopic control mechanism 3 and the rotation control mechanism 4 are both connected on the controller.

[0029] Sp...

Embodiment 2

[0039] This embodiment is similar to Embodiment 1, the difference is that the distribution bucket turning device of this embodiment also includes a second bucket turning structure opposite to the first bucket turning structure, and the second bucket turning structure is the same as the first bucket turning structure. The structure has the same structure, and the keg 6 is located between the first turning structure and the second turning structure. Of course, if Figure 8 As shown, the outer wall of the keg here has two opposite pressure grooves 61 .

[0040] When put into use, the keg 6 is placed in the middle of the first turning structure and the second turning structure. After the installation is completed, the bucket turning action can be started. Here, the opposite resistance force on both sides is mainly used to complete the bucket turning action on the keg 6 to ensure the stability of the keg 6, and here the pressing platform 12 is circumferentially outward and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com