Piston head

A technology for piston head and pressure relief, applied in the field of piston head, can solve the problems of lower reliability of internal combustion engine, increase of crankcase pressure, air leakage of intake valve or exhaust valve, etc., so as to reduce the consumption of lubricating oil and improve the lubricating performance. , to avoid the effect of increased pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

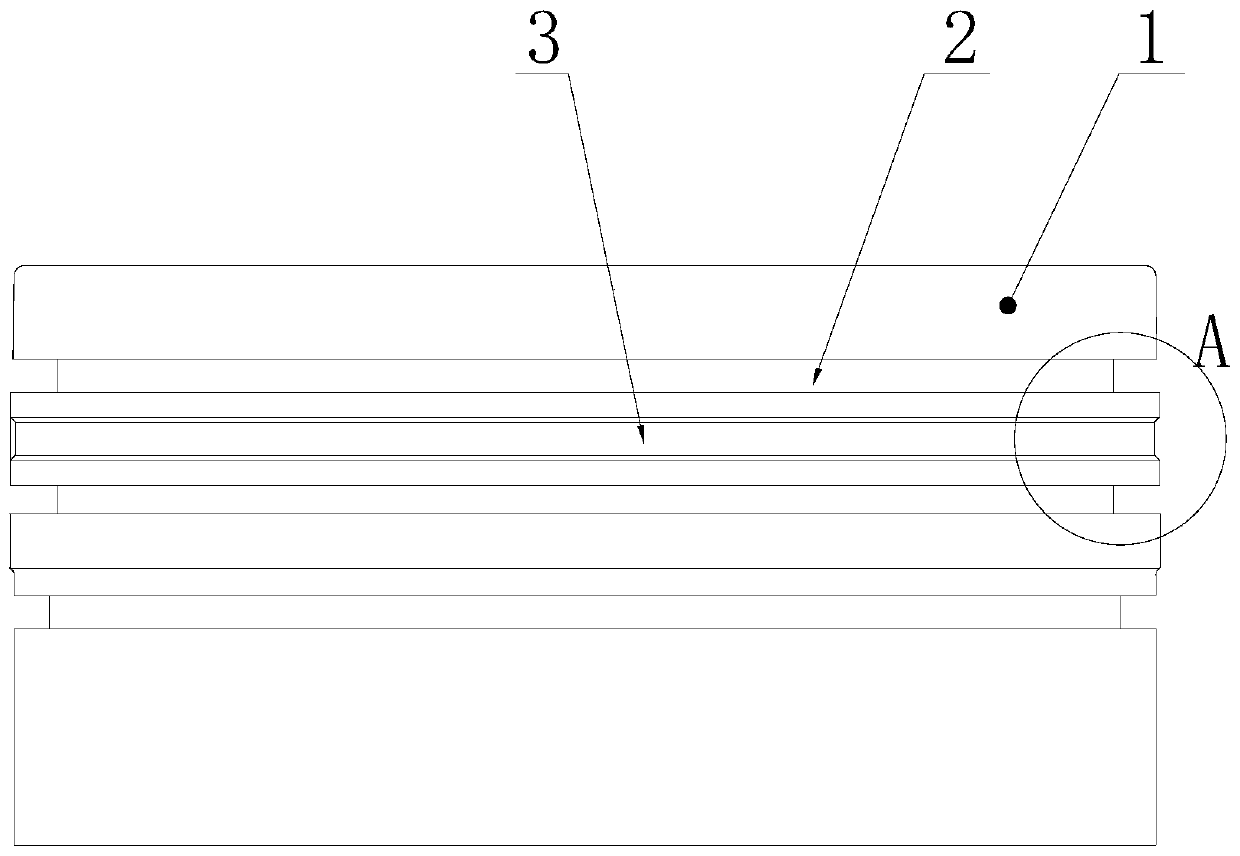

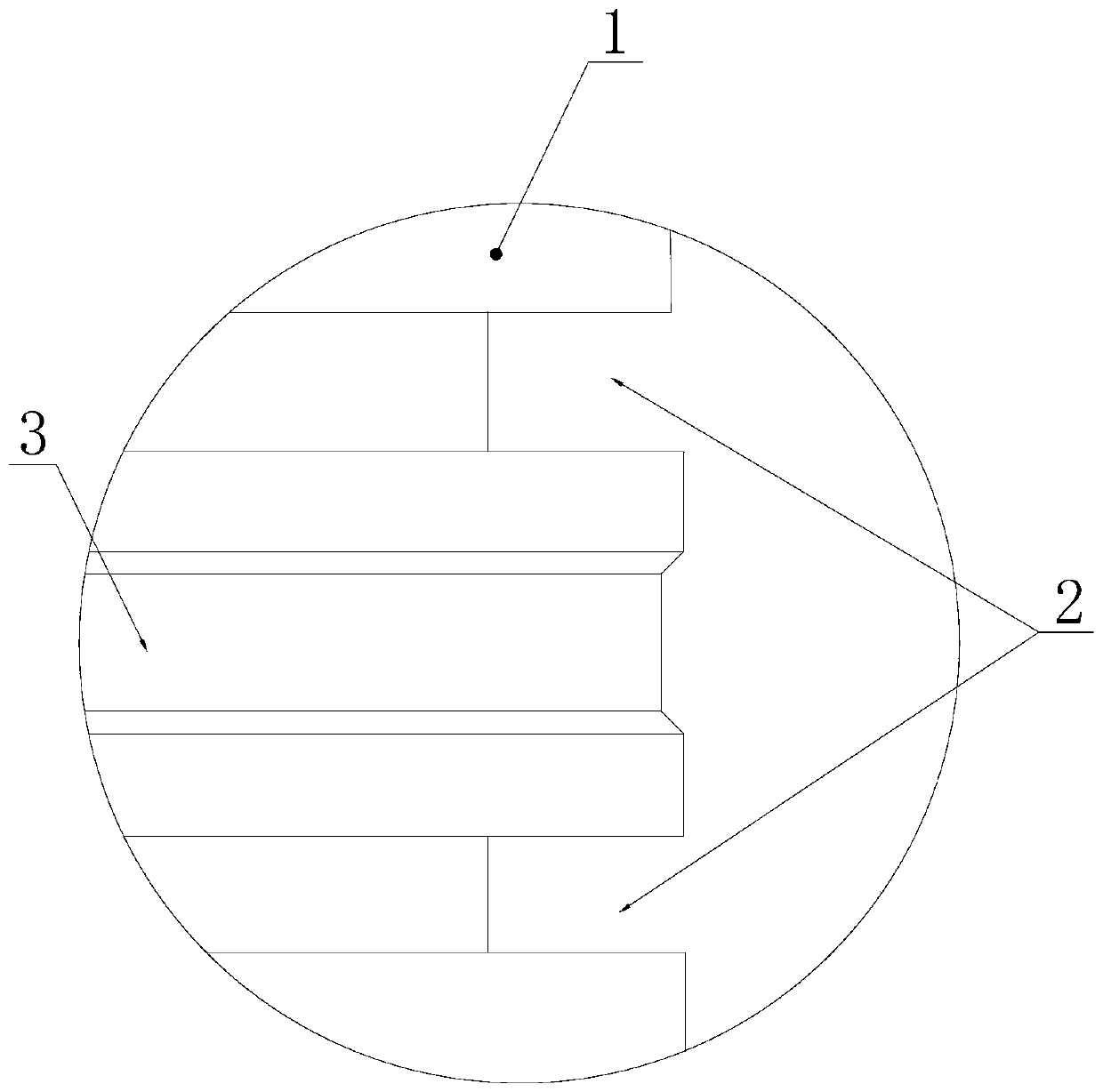

[0020] see figure 1 and figure 2 , is a specific embodiment of a piston head. The piston head includes a piston head body 1. In this embodiment, the diameter of the piston head body is 208 mm, which is formed by processing conventional materials in the field of gas engines. The circumferential side wall of the piston head body 1 is provided with at least two seal ring grooves 2 for installing seal rings, and there is a distance between adjacent seal ring grooves 2. In this embodiment, the number of seal ring grooves is Three, from top to bottom are the first seal ring groove, the second seal ring groove, and the third seal ring groove. The three seal ring grooves are all processed into conventional seal ring grooves in the field of gas engines, and are used to install gas The ring can also be used to install the oil ring according to actual needs, and the distance between the first sealing ring groove and the second sealing ring groove is 16mm. A pressure relief cut-off ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com