Pipe culvert-soil interaction test system and test method thereof for uneven deformation

A test system, uniform deformation technology, applied in the field of pipe and culvert test system, to achieve the effect of reliable test results, good practicability and adaptability, and simple structure of the test system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

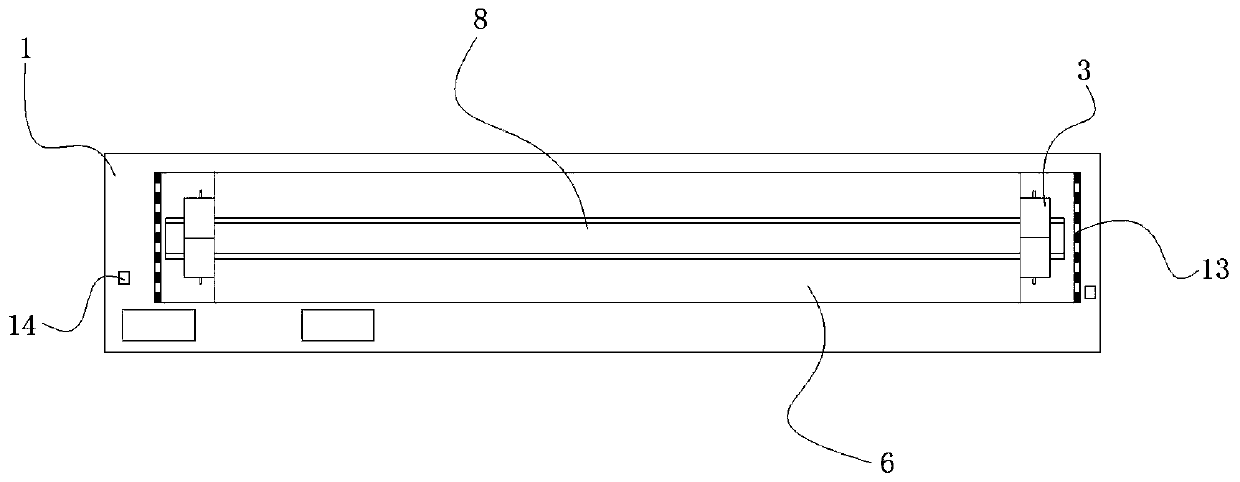

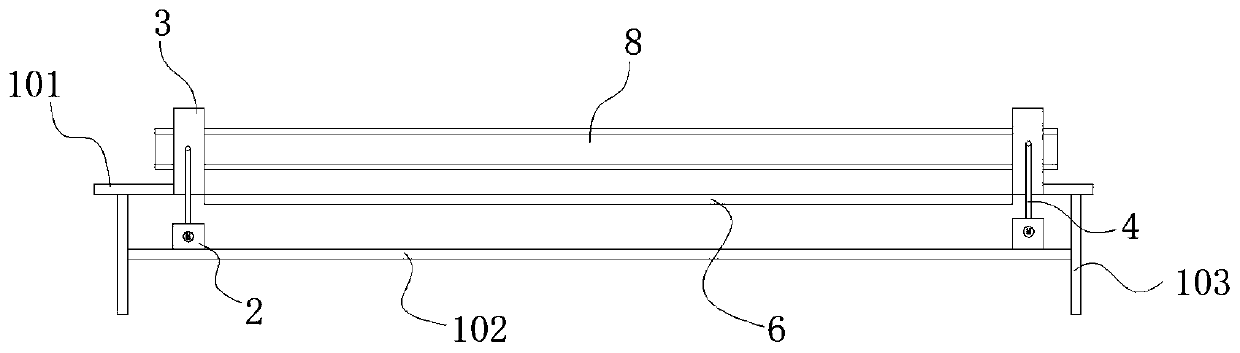

[0030] see figure 1 and figure 2 , this embodiment discloses a pipe-culvert-soil interaction test system for uneven deformation, including a test bench 1, a pipe-culvert test tank, two sets of driving systems and a test data acquisition system.

[0031] The test bench 1 includes an upper platform board 101 and a lower platform board 102 , and supporting legs 103 supporting the upper platform board 101 and the lower platform board 102 . A rectangular hole 1011 is arranged on the surface of the upper platform board 101 .

[0032] see Figure 4 , the pipe culvert test tank includes a test tank bottom plate 6 and two test tank side plates 5 . The bottom plate 6 of the test tank is fixed on the lower surface of the upper platform plate 101 . The bottom plate 6 of the test tank blocks the middle part of the rectangular hole 1011 . The side plate 5 of the test tank is arranged vertically on the upper surface of the bottom plate 6 of the test tank.

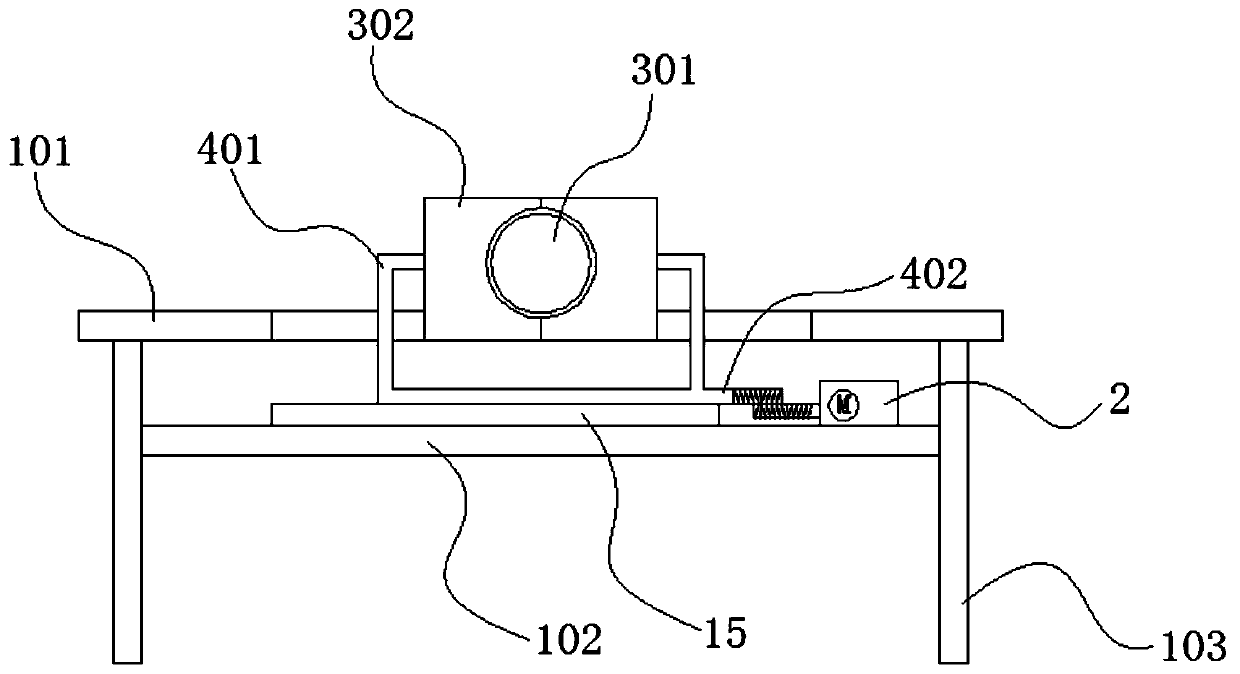

[0033] see image 3 , each...

Embodiment 2

[0038] This embodiment discloses a test method for the pipe and culvert test system described in Example 1, comprising the following steps:

[0039] 1) Put the test bench 1 in an appropriate position and turn on the power. Adjust the two sets of pipe culvert clamps 3 to their original positions.

[0040] 2) Place the pipe culvert 8 in the center and clamp it with the pipe culvert clamp 3 .

[0041] 3) Apply lubricating oil on the upper surface of the bottom plate 6 of the test tank. Soil is filled in the rectangular frame until the soil covers the upper surface of the pipe culvert 8 .

[0042] 4) Set up the test data acquisition system, and read the initial value after debugging.

[0043] 5) Adjust the transmission rod 4 to simulate the settlement of the pipe culvert 8 .

[0044] 6) Record the reading of the pointer on the scale according to the number of the test bench, and the monitoring equipment collects the test data.

[0045] 7) Remove the test data acquisition syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com